Harmlessness treatment method for freon

A treatment method, freon technology, applied in the field of environmental engineering technology and chemical industry, can solve the problems of easy deactivation of catalysts, carbon deposition in equipment, residual chemical reagents, etc., to reduce production costs and operating costs, high conversion efficiency, simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

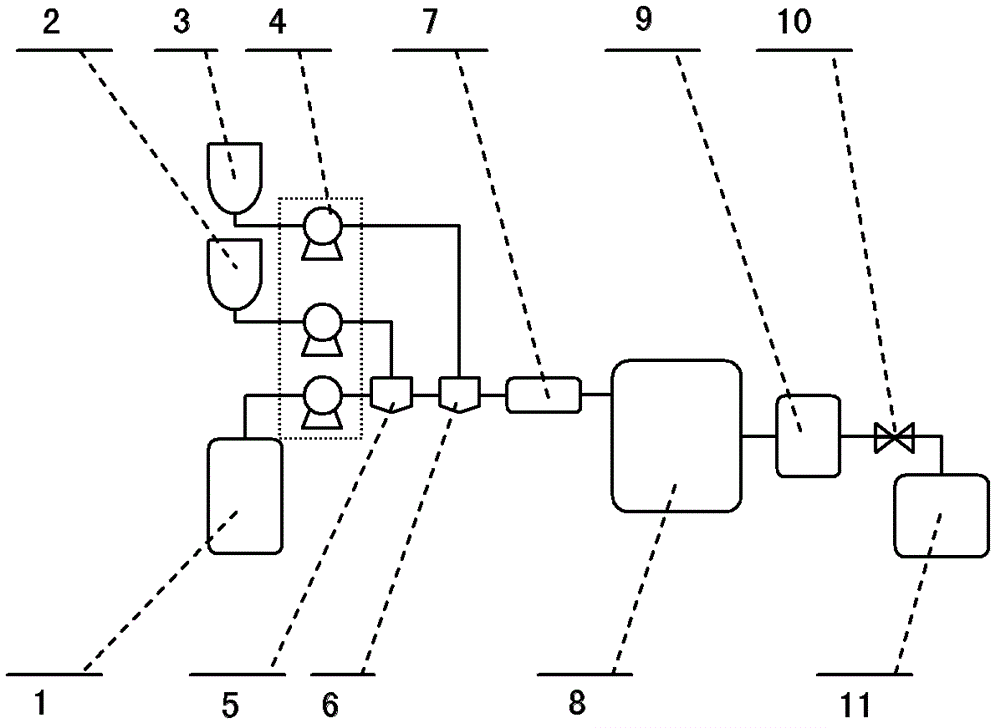

Image

Examples

Embodiment 1

[0029] In an autoclave hydrothermal reactor, Freon 12 (CF 2 Cl 2 , R12) for decomposition treatment, the oxidizing agent H 2 o 2 The addition rate is 60%, the molar ratio of NaOH and R12 is 5:1, placed in a SUS 316 hydrothermal tube reactor, and the water filling rate is controlled to be 35%. After the hydrothermal oxidation reaction was carried out at a temperature of 200° C. and a pressure of 20 MPa for 6 minutes, the reactor was quickly taken out, cooled with water, and the reaction was terminated. Quantitative analysis by HPLC showed that the decomposition rate of Freon reached 99.9%.

Embodiment 2

[0031] In an autoclave hydrothermal reactor, Freon 22 (CHF 2 Cl, R22) for decomposition treatment, the oxidizing agent H 2 o 2 The addition rate is 80%, the molar ratio of KOH and R12 is 6:1, placed in a SUS 316 hydrothermal tube reactor, and the water filling rate is controlled to be 35%. After the hydrothermal oxidation reaction was carried out at a temperature of 250° C. and a pressure of 26 MPa for 10 minutes, the reactor was quickly taken out, cooled with water, and the reaction was terminated. Quantitative analysis by HPLC showed that the decomposition rate of Freon reached 100%.

Embodiment 3

[0033] Using a continuous hydrothermal reactor, Freon 22 (CHF 2 Cl, R22) for decomposition treatment, the oxidizing agent H 2 o 2 The addition rate is 80%, the molar ratio of NaOH and R12 is 6:1, the temperature of the hydrothermal system is controlled at 200° C., and the pressure is 20 MPa to carry out continuous hydrothermal decomposition of Freon. HPLC analysis of the product showed that the decomposition rate of Freon reached 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com