Alkaline earth fluoride nano granule preparation method

An alkaline earth metal and nanoparticle technology is applied in the preparation of chlorides, calcium/strontium/barium fluoride, magnesium fluoride, etc., and achieves the effects of simple preparation method, simple process operation, and easy large-scale preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

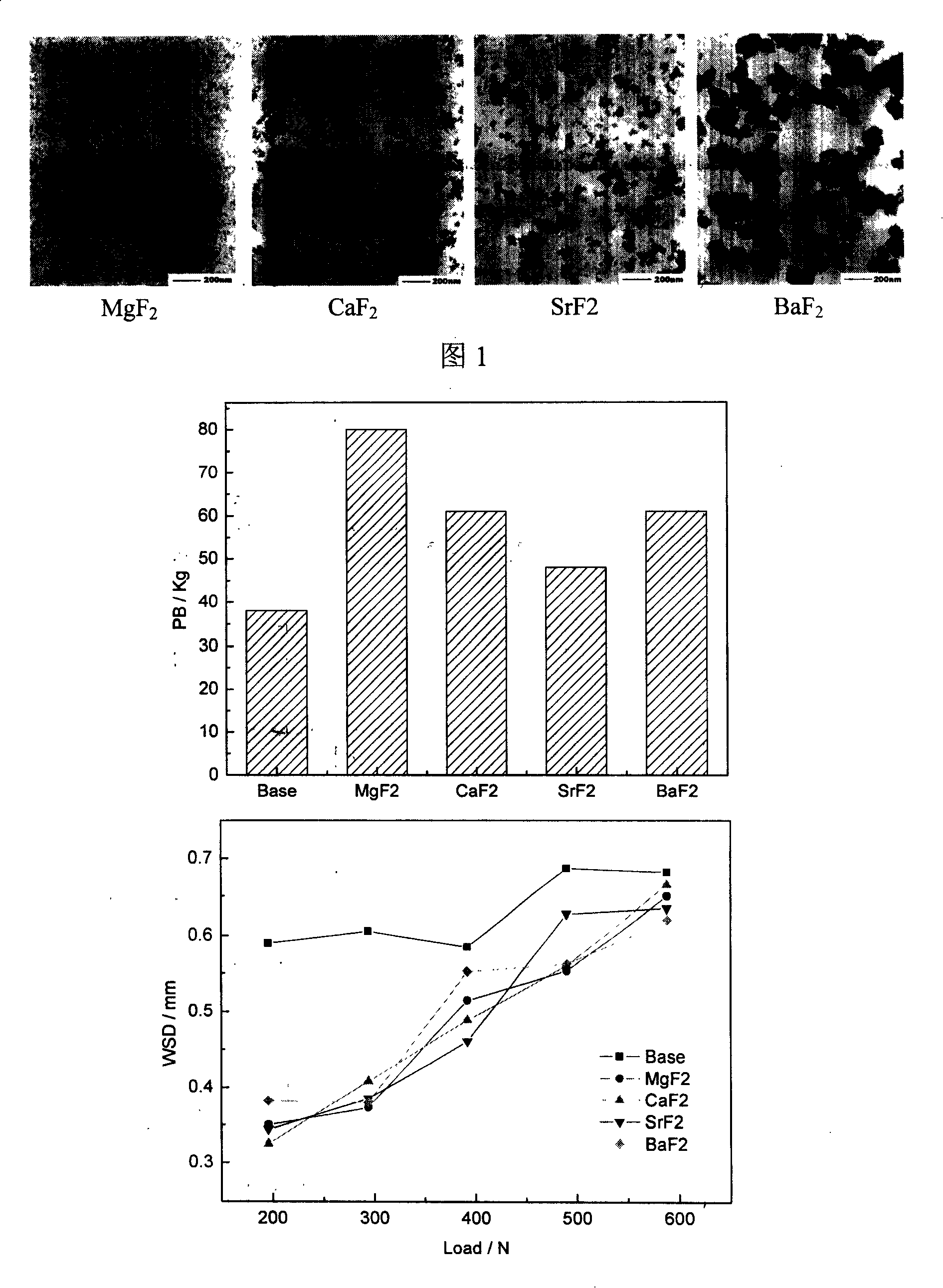

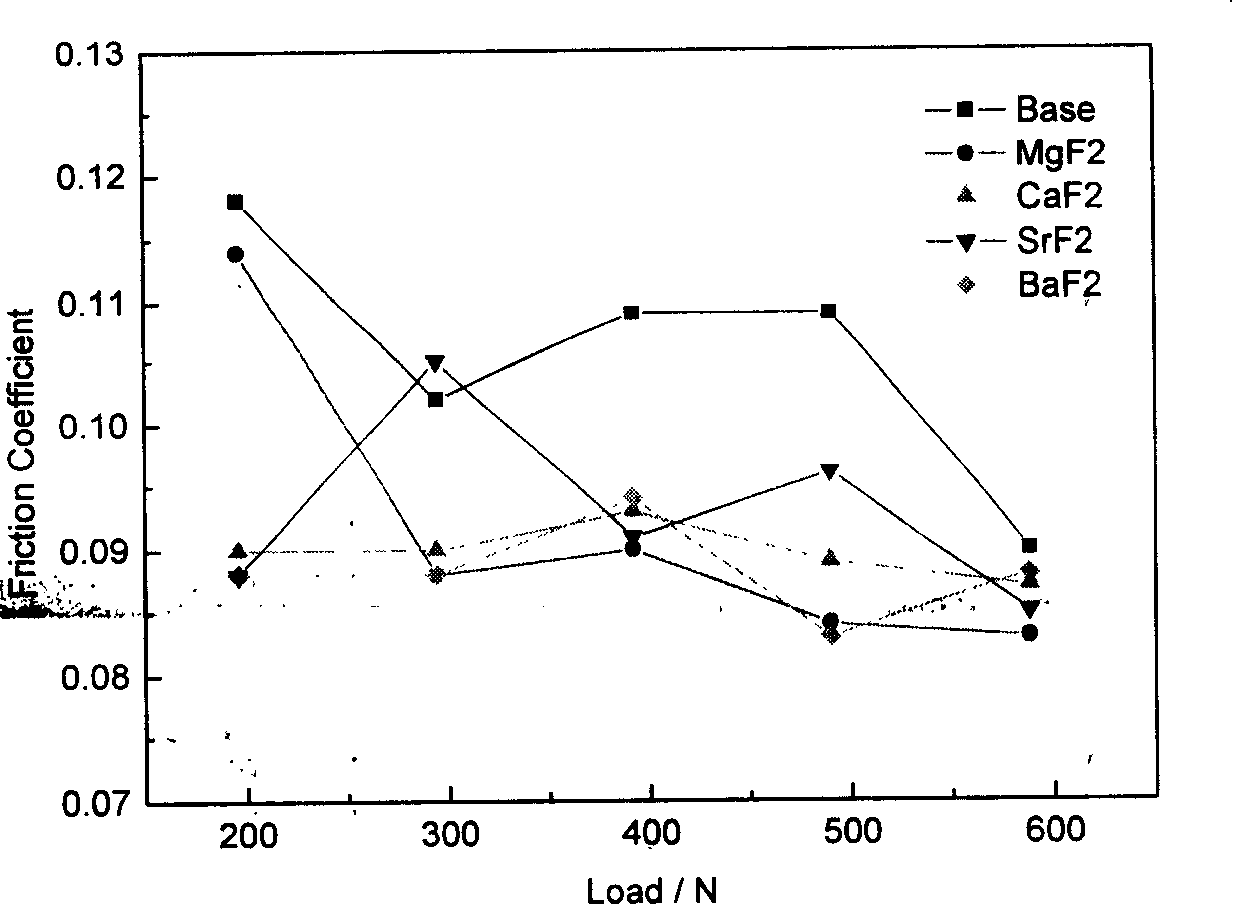

Image

Examples

Embodiment 1

[0017] Dissolve 0.01mol of magnesium chloride and 0.02mol of ammonium fluoride in 100ml of water respectively. After the dissolution is complete, slowly add the ammonium fluoride aqueous solution to the magnesium chloride solution under strong stirring, stir and react at room temperature for 2-5 hours, centrifuge, wash, Vacuum drying to obtain white magnesium fluoride nanoparticles.

Embodiment 2

[0019] Dissolve 0.01mol of calcium chloride and 0.02mol of ammonium fluoride in 100ml of water respectively. After the dissolution is complete, under strong stirring, slowly add the ammonium fluoride aqueous solution to the calcium chloride solution, and stir at room temperature for 2-5 hours. Centrifuge, wash, and vacuum-dry to obtain white calcium fluoride nanoparticles.

Embodiment 3

[0021] Dissolve 0.01mol of strontium chloride and 0.02mol of ammonium fluoride in 100ml of water respectively. After the dissolution is complete, under strong stirring, slowly add the ammonium fluoride aqueous solution to the strontium chloride solution, and stir at room temperature for 2-5 hours. Centrifuge, wash, and vacuum-dry to obtain white strontium fluoride nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com