Refractory compound powder material preparation device and preparation method

A powder material and preparation device technology, applied in the field of powder metallurgy, can solve the problems of many intermediate links, difficult to remove, and affect the purity of refractory compound materials, and achieve the effects of small environmental impact, solving synthesis problems, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 Preparation device and preparation method of refractory compound powder material of the present invention

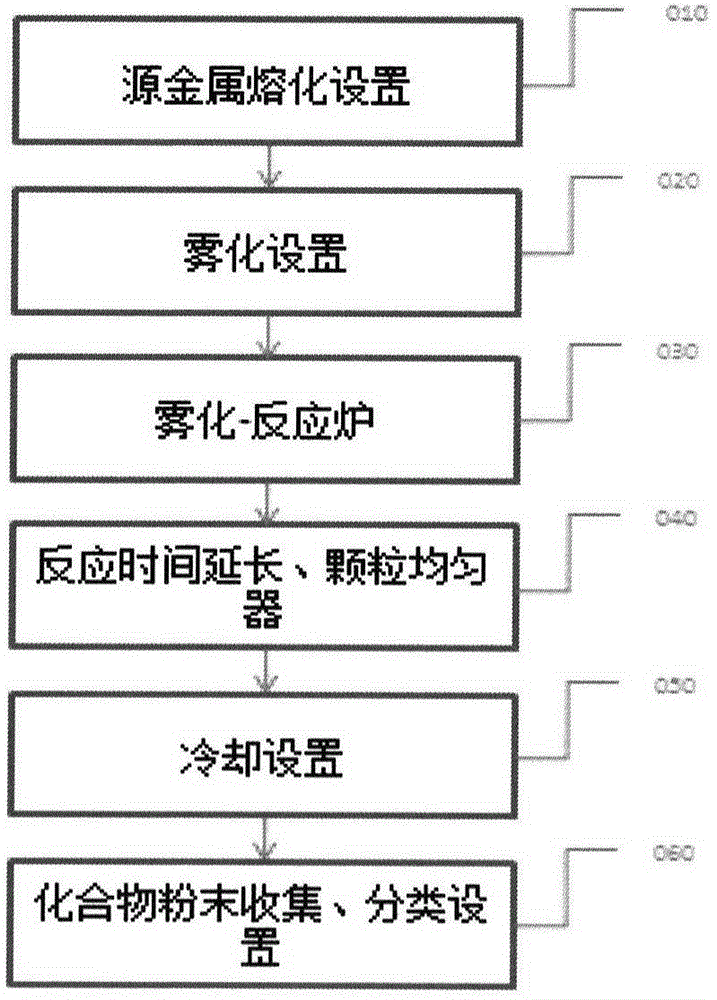

[0025] figure 1 It is a schematic flow chart of the method according to the present invention, relates to a refractory compound powder material preparation device, including the following settings:

[0026] Set 010, smelting setting, heat the source metal to melt it;

[0027] Set 020, atomization setting, atomize the molten metal to make it into droplets;

[0028] Set 030, the reaction furnace, to allow the metal droplets to react with the reaction gas, so that the metal droplets are converted into refractory compound powder;

[0029] Set 040, extend the reaction time, particle homogenizer, execute the reaction, post-synthesis processing;

[0030] Set 050, cooling settings, to perform particle cooling treatment;

[0031] Setting 060, Particle Collection and Classification Setup, performs particle collection and classification of refractory compoun...

Embodiment 2

[0042] Embodiment 2 Refractory compound powder material preparation device of the present invention

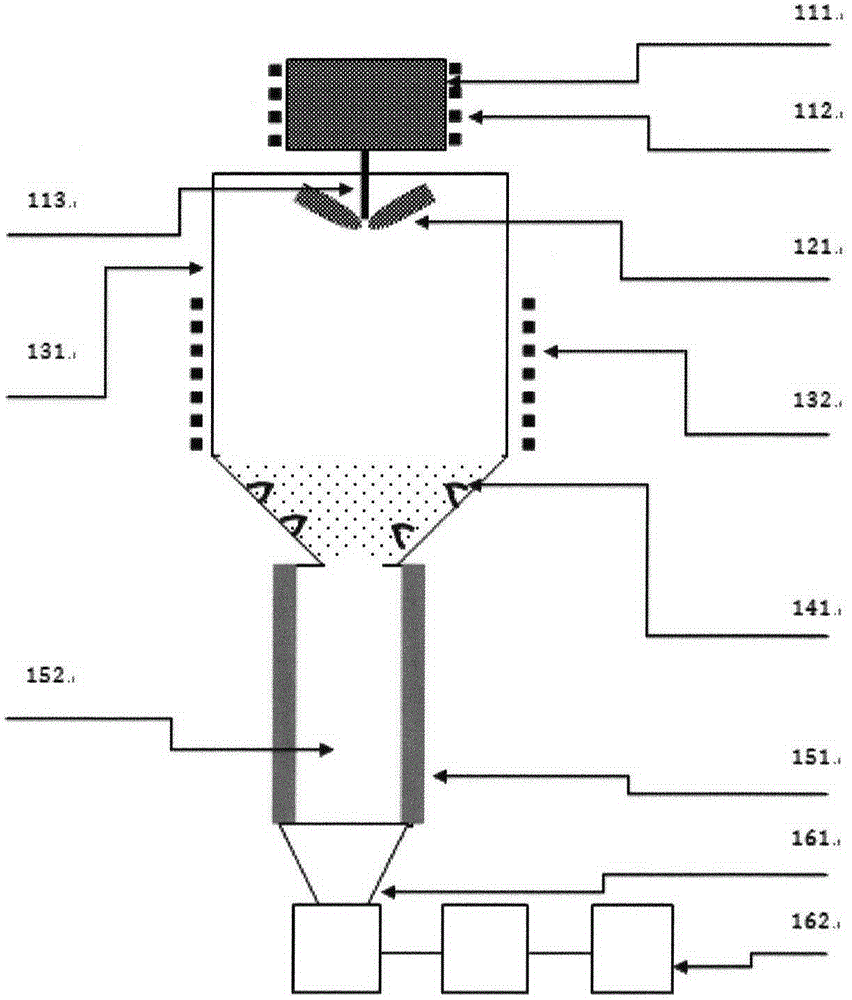

[0043] figure 2 It is a schematic diagram of the device structure of Example 1 provided by the present invention, which relates to a high-purity, refractory compound powder material preparation device, including the following:

[0044] Set 111, the source metal crucible (container), cylindrical or conical, made of high temperature resistant materials (such as: stainless steel, graphite, zirconia, boron nitride, aluminum nitride);

[0045] Setting 112, a crucible heater, is located on the periphery of the source metal crucible. Heating methods are: resistance heating, electromagnetic induction heating. Resistive heating has low cost but slow heating speed; while electromagnetic induction heating has fast heating speed but high cost;

[0046] Setting 113, metal liquid guide pipe, made of high temperature resistant materials (such as: stainless steel, graphite, zirconia, boro...

Embodiment 3

[0055] Embodiment 3 Refractory compound powder material preparation device of the present invention

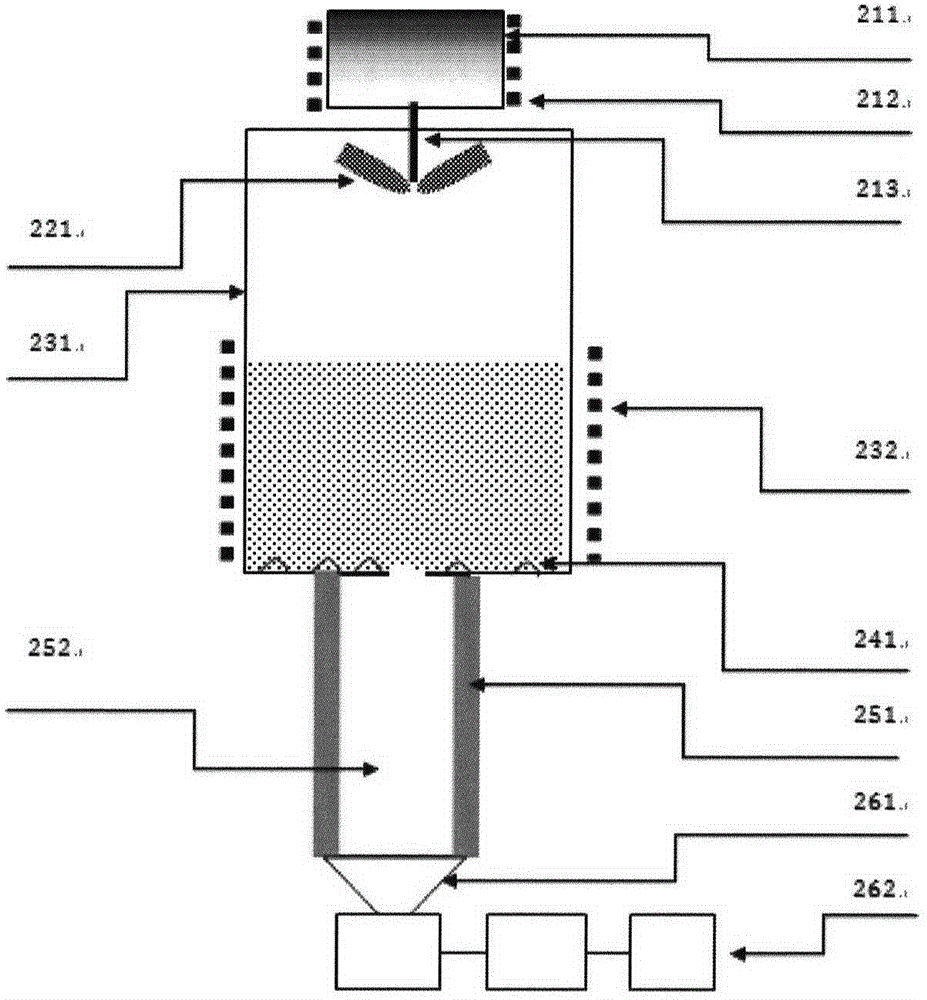

[0056] image 3 It is a schematic diagram of the device structure of Example 2 provided by the present invention, which relates to a high-purity, refractory compound powder material preparation device, including the following:

[0057] Set 211, the source metal crucible (container), cylindrical or conical, made of high temperature resistant materials (such as: stainless steel, graphite, zirconia, boron nitride, aluminum nitride);

[0058] Setting 212, a crucible heater, is located on the periphery of the source metal crucible. Heating methods are: resistance heating, electromagnetic induction heating. Resistive heating has low cost but slow heating speed; while electromagnetic induction heating has fast heating speed but high cost;

[0059] Setting 113, metal liquid guide pipe, made of high temperature resistant materials (such as: stainless steel, graphite, zirconia, boron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com