Carbon fiber electrode used for diphenol microsensor

A carbon fiber electrode and micro sensor technology, applied in the field of electrochemistry, can solve the problems of small RC time constant of electrochemical cell, reduction of electric double layer capacitance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

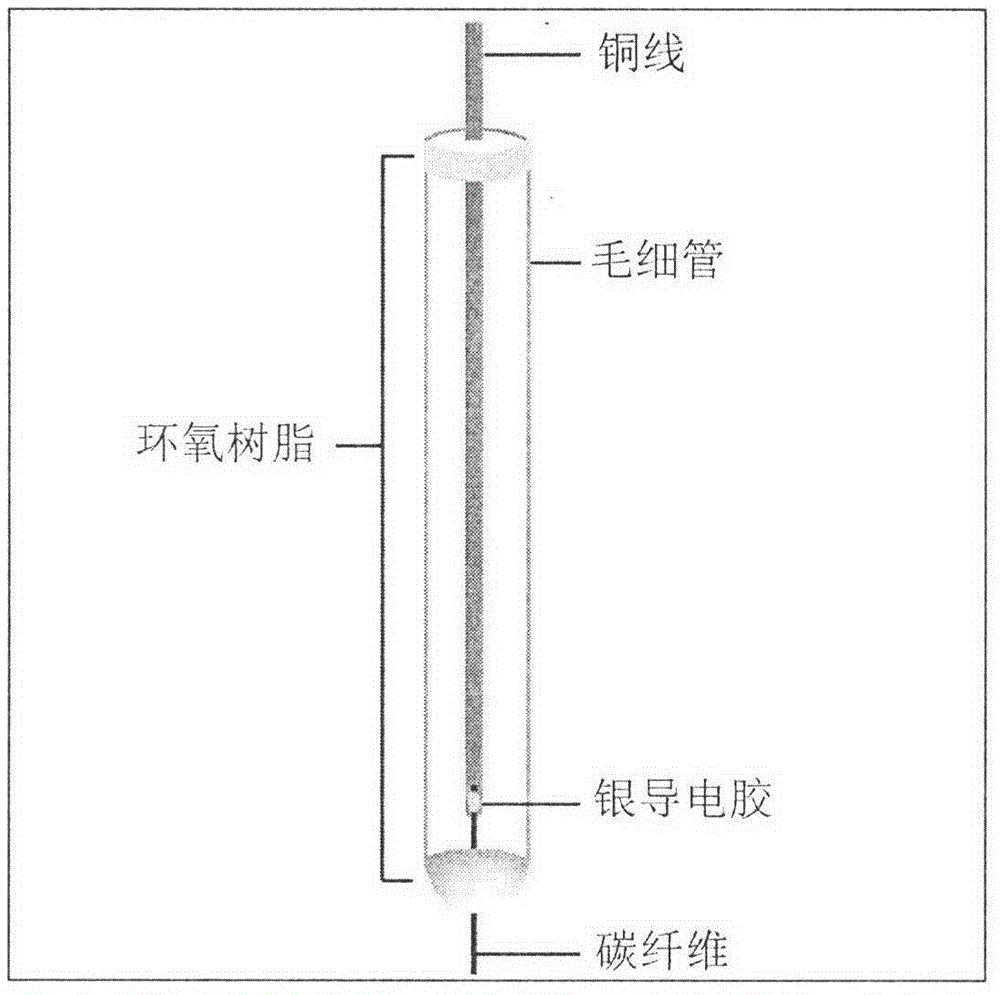

[0020] Assembly of carbon fiber electrodes

[0021] (1) Sonicate a carbon fiber with a diameter of about 6 μm in acetone and distilled water for 2 to 3 minutes, select a carbon fiber to bond the carbon fiber and copper wire with silver conductive glue, and dry at room temperature;

[0022] (2) Cut the capillary to a length of 5-6 cm, burn both ends of the capillary with an alcohol lamp to make the opening shrink smaller, and use it for packaging;

[0023] (3) Encapsulate the bonded carbon fiber in the capillary with epoxy resin, fully dry it at room temperature, and then cut the length of the exposed carbon fiber to 0.8-1mm.

Embodiment 2

[0025] carbon fiber modification

[0026] (1) Immerse the assembled carbon fiber electrode in dilute H 2 SO 4 , the potential is set to 0V ~ 1.7V, and the cyclic voltammetry scan is performed until a stable cyclic voltammetry image appears;

[0027] (2) Immerse the assembled electrode into an acetonitrile solution containing a certain concentration of lithium perchlorate and EDOT monomer, and pass high-purity nitrogen gas for several minutes to eliminate the interference of oxygen. The constant potential polymerization is adopted, the polymerization potential is set at 1.2-1.4V, and the polymerization time is set at 10-15s.

Embodiment 3

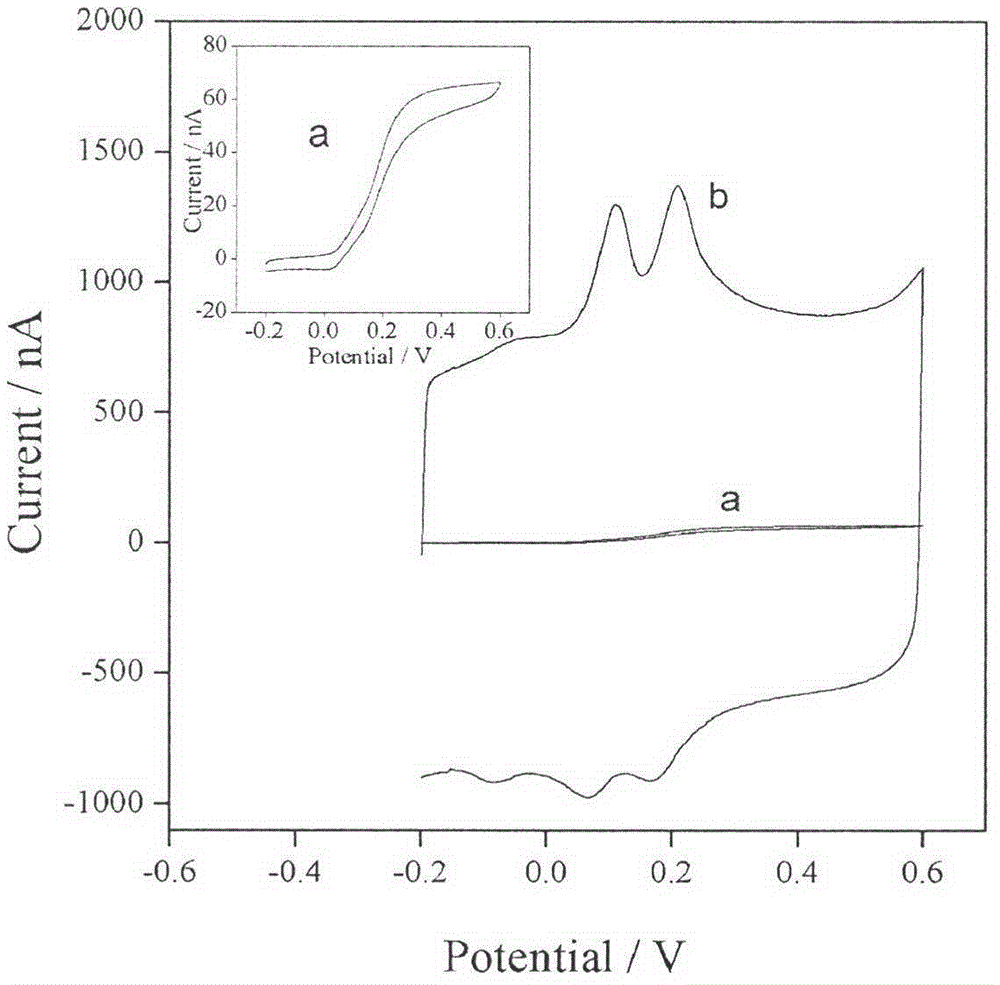

[0029] Detection of hydroquinone and catechol

[0030] (1) Add a certain concentration of hydroquinone and pyrocatechol into the PBS buffer solution with a pH of 7, carry out cyclic voltammetry scanning at a potential of -0.2V to 0.6V, and a scan rate of 0.1V / s. Oxidation potentials of hydroquinone and catechol were observed;

[0031] (2) Using the standard addition method, hydroquinone and catechol were added to the constantly stirring PBS solution at their respective oxidation potentials, and the respective detection ranges and detection limits were calculated on the obtained current-time curves.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com