Electrochemical modification treatment method of carbon fiber surface

A treatment method, carbon fiber electrode technology, applied in fiber treatment, physical treatment, anodic oxidation, etc., can solve the problems that the deposition process is difficult to control, difficult to realize industrialization, etc., and achieve mild treatment conditions, simple operation, and controllable graft density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Reflux the multi-walled carbon nanotubes with aqua regia (concentrated nitric acid: concentrated sulfuric acid=1:3) for 9-10 hours, centrifuge for 15 minutes, discard the upper solution part, wash the precipitate with deionized water, and then centrifuge for 15 minutes, repeat the process Step 3 times. Dry in an oven at 60°C for 12 hours. Then weigh 0.1 mg of the above-mentioned carboxylated carbon nanotubes and dissolve them in 10 mL of acetonitrile solution, disperse them evenly with ultrasonic waves, and prepare a 0.01 mg / mL electrolyte solution.

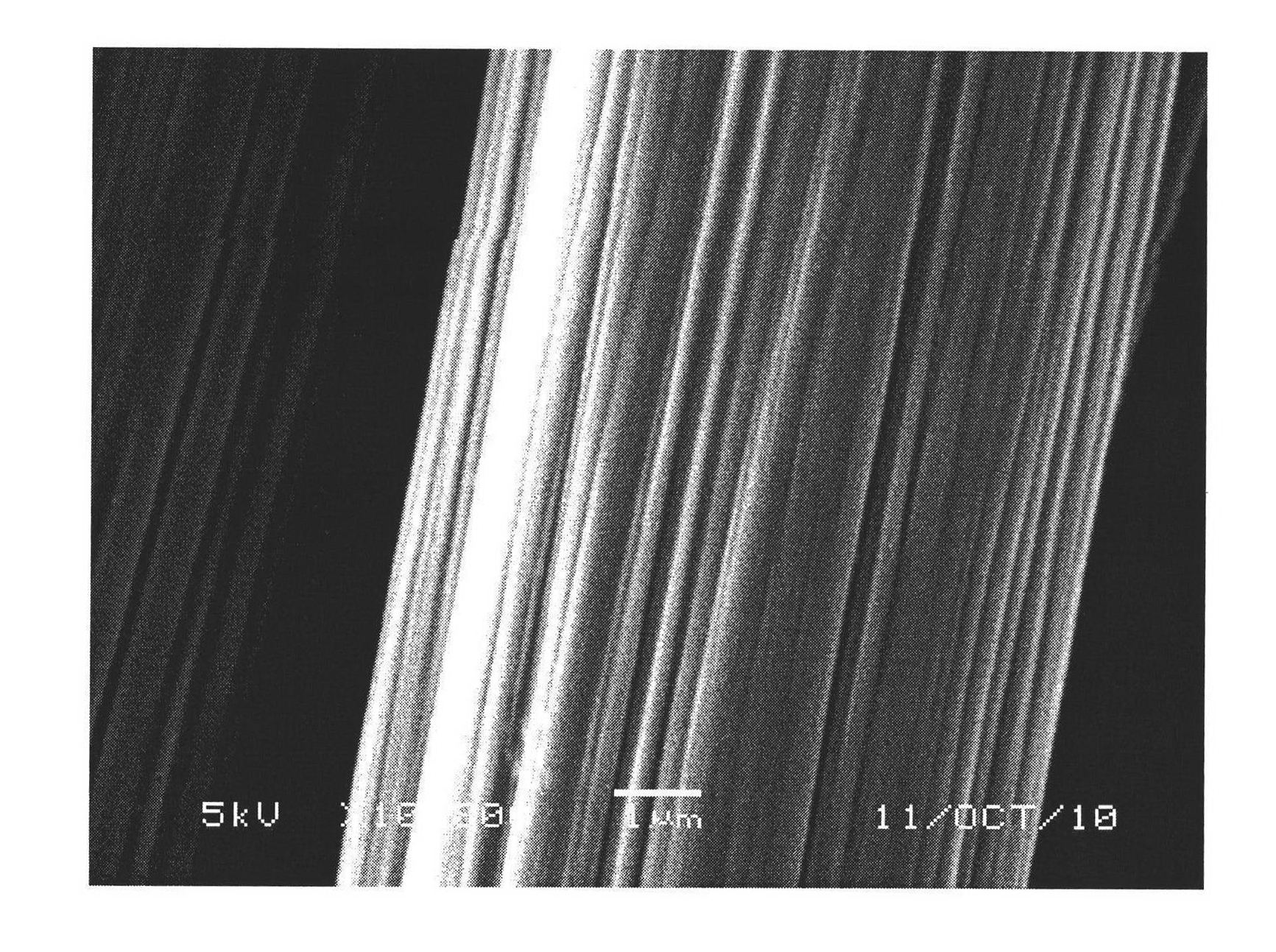

[0026] Take polyacrylonitrile carbon fiber and wind it on the tetrafluoroethylene plate as the anode electrode of the electrochemical workstation. figure 1 is a scanning electron microscope image of polyacrylonitrile carbon fiber. In the electrolyte solution, the platinum electrode was used as the cathode electrode, the temperature of the solution was controlled at 25°C, and a constant voltage of 1.0V was applied to the ...

Embodiment 2

[0028] Carboxylation-modified multi-walled carbon nanotubes were prepared according to the method shown in Example 1, and dried in an oven at 80° C. for 6 hours. Weigh 100 mg of the above-mentioned carboxylated carbon nanotubes and disperse them in 10 ml of tetrahydrofuran solution, uniformly disperse them with ultrasonic waves, and prepare a 10 mg / mL electrolyte solution.

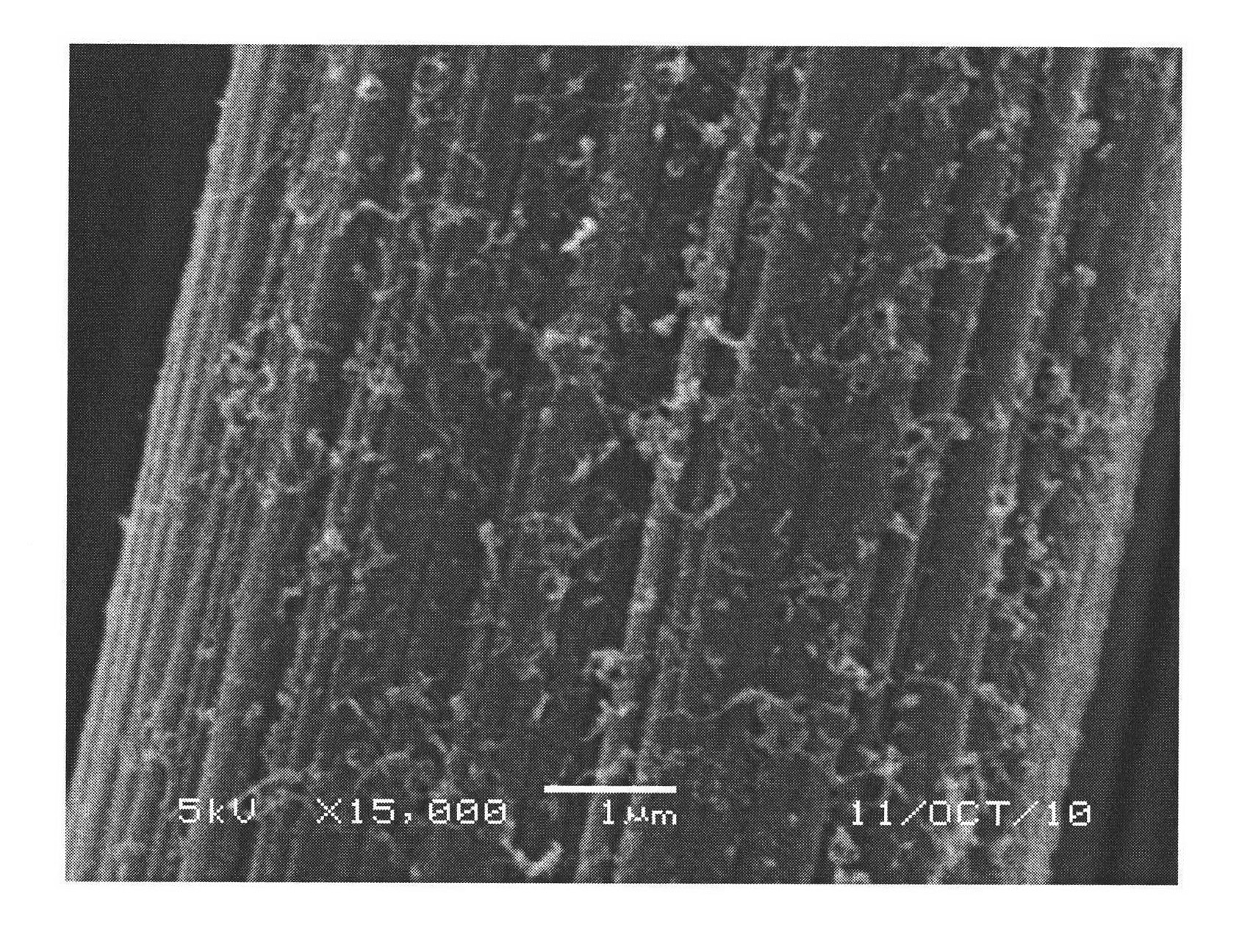

[0029] Take polyacrylonitrile carbon fiber and wind it on a tetrafluoroethylene plate as the anode of the electrochemical workstation, the platinum wire as the cathode, and the Ag / AgCl electrode as the reference electrode. The carbon fibers were immersed in the electrolyte solution at a temperature of 25 ° C, and a voltage of 5 V was applied to electrolyze for 30 minutes through a CHI660A electrochemical workstation, and ultrasonic waves were applied during the process to disperse. Then the carbon fiber was taken out, cleaned by ultrasonic wave for 30 minutes, and then dried at 120° C. for 4 hours to obtai...

Embodiment 3

[0031] Single-walled carbon nanotubes were taken, and carboxylated-modified single-walled carbon nanotubes were prepared by the method shown in Example 1, and dried in a drying oven at 80° C. for 6 hours. Weigh 50 mg of the dried carboxylated carbon nanotubes and dissolve them in 10 mL of ethanol to prepare a 5 mg / mL electrolyte solution.

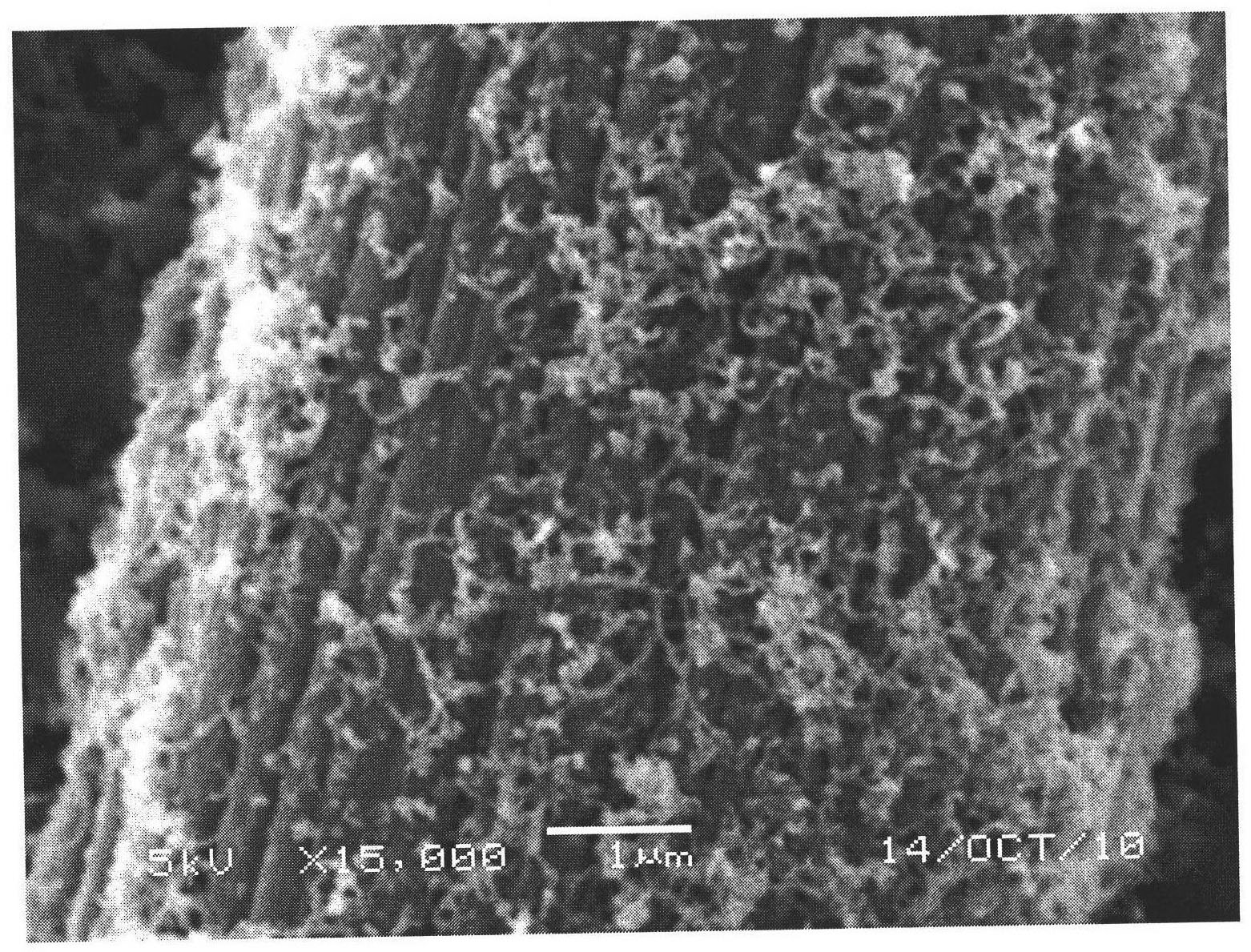

[0032] The polyacrylonitrile carbon fiber was wound on the tetrafluoroethylene plate as the anode of the electrochemical workstation, the platinum wire was used as the counter electrode, and the Ag / AgCl electrode was used as the reference electrode. The carbon fiber is immersed in the electrolyte solution, the pH of the solution is controlled at 10.0 and the temperature is 25 ° C, and the carbon fiber electrode is treated with a constant current of 10 mA for 30 minutes through the Autolab electrochemical workstation, and ultrasonic waves are applied during the process for effective dispersion. Then the carbon fibers were taken out, cleaned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com