Active carbon fiber electrodes undivided paired direct electro-oxidation and electro-reduction decolorizing method

An activated carbon fiber and electro-oxidation technology, applied in chemical instruments and methods, oxidized water/sewage treatment, reduced water/sewage treatment, etc., can solve the problems of high efficiency and low consumption, reduce power consumption, improve current efficiency and decolorization efficiency , The effect of solving the problem of high-efficiency and low-consumption decolorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

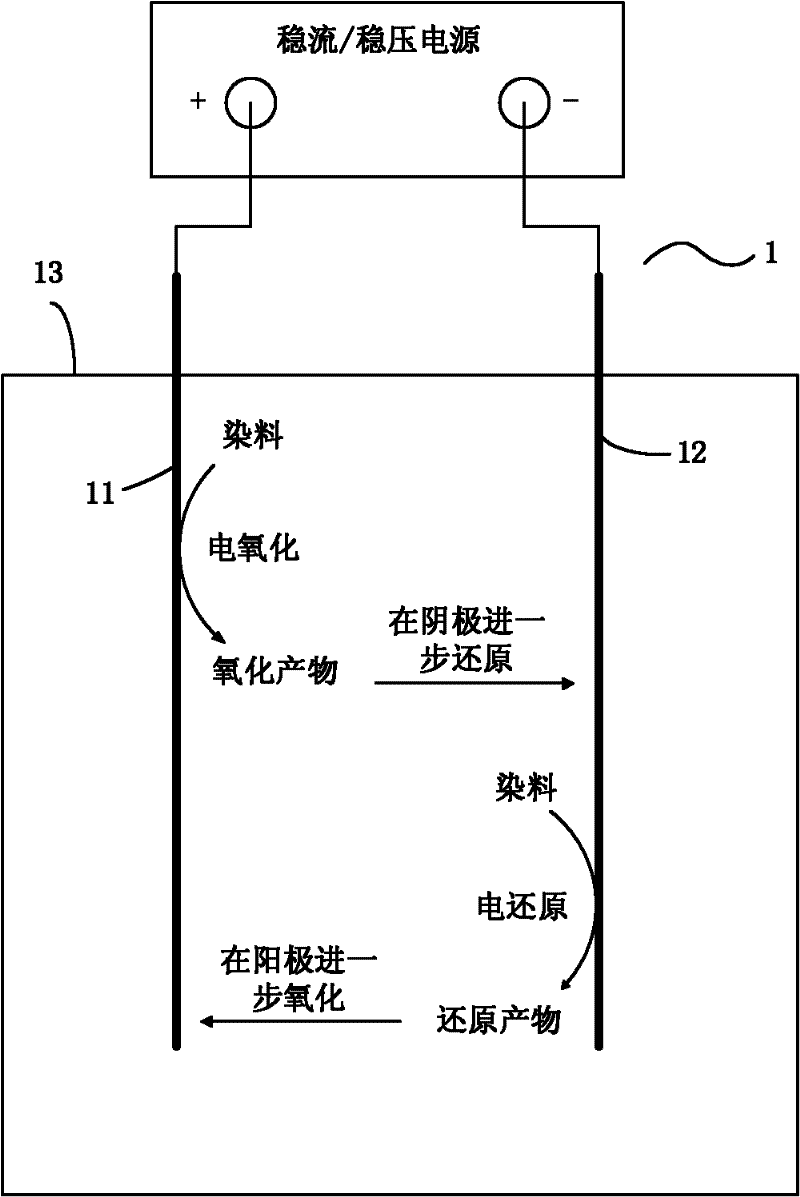

[0032] The reactive brilliant blue KN-R dye waste water that initial concentration is 250mg / L imports in the reaction tank 13 without diaphragm that establishs an activated carbon fiber anode 11 and an activated carbon fiber cathode 12 inside, connects the stabilized voltage / steady current power supply to the activated carbon fiber Anode 11 and activated carbon fiber cathode 12, after electrification, the ACF anode is positively polarized at a potential of 0.6V for 2 hours, and the ACF cathode is negatively polarized at a potential of -0.8V for 2 hours, and then the current density is controlled to 1.0 ~ 1.1mA / cm 2 , paired direct electro-redox decolorization degradation of dye wastewater, the highest decolorization rate reaches 87%.

[0033] Its specific implementation method and process are as follows:

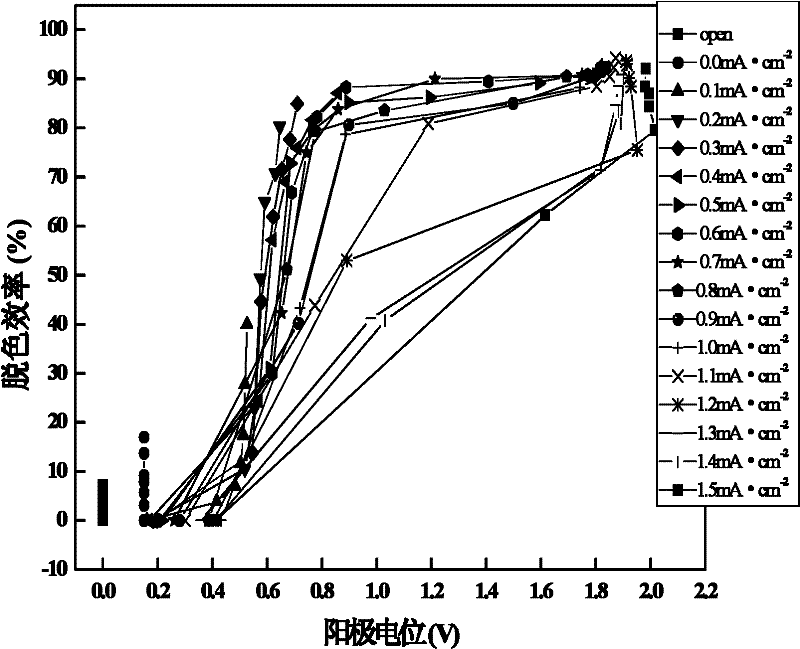

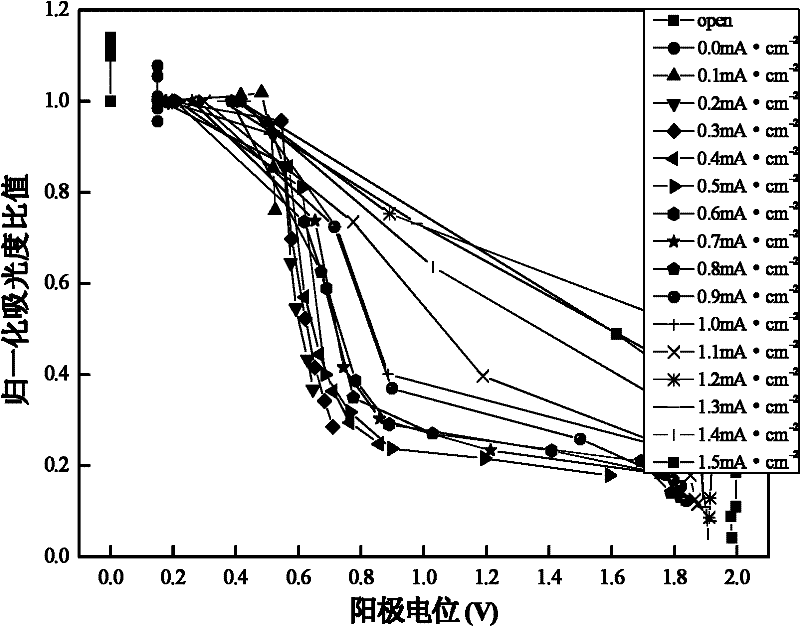

[0034] Such as figure 2 Shown is a schematic diagram of the relationship curve between the decolorization rate of reactive brilliant blue KN-R dye wastewater and the anode...

Embodiment 2

[0041] The second embodiment of the present invention differs from the first embodiment in that, for the amaranth dye wastewater with an initial concentration of 250mg / L, after power-on, the ACF anode is positively polarized for 2 hours at a potential of 0.6V, and the ACF cathode is positively polarized at a potential of 0.6V. Negative polarization at -0.4V potential for 2 hours, and then control the current density to 0.7-0.9mA / cm 2 , paired direct electro-redox decolorization of dye wastewater, the decolorization rate is as high as 96%.

[0042] Its specific implementation method and process are as follows:

[0043] Such as Figure 11 Shown is a schematic diagram of the relationship between the decolorization rate of amaranth dye wastewater and the anode potential. Such as Figure 12 Shown is a schematic diagram of the relationship between the normalized absorbance ratio of amaranth dye wastewater and the anode potential. In an electrolyzer with a diaphragm, according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com