Undivided paired direct electro-oxidation and electro-reduction reactor utilizing activated carbon fiber electrode

An activated carbon fiber and electro-oxidation technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as high efficiency and low consumption, and achieve reduced power consumption, improved current efficiency and decolorization Efficiency, solving the effect of high-efficiency and low-consumption decolorization treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

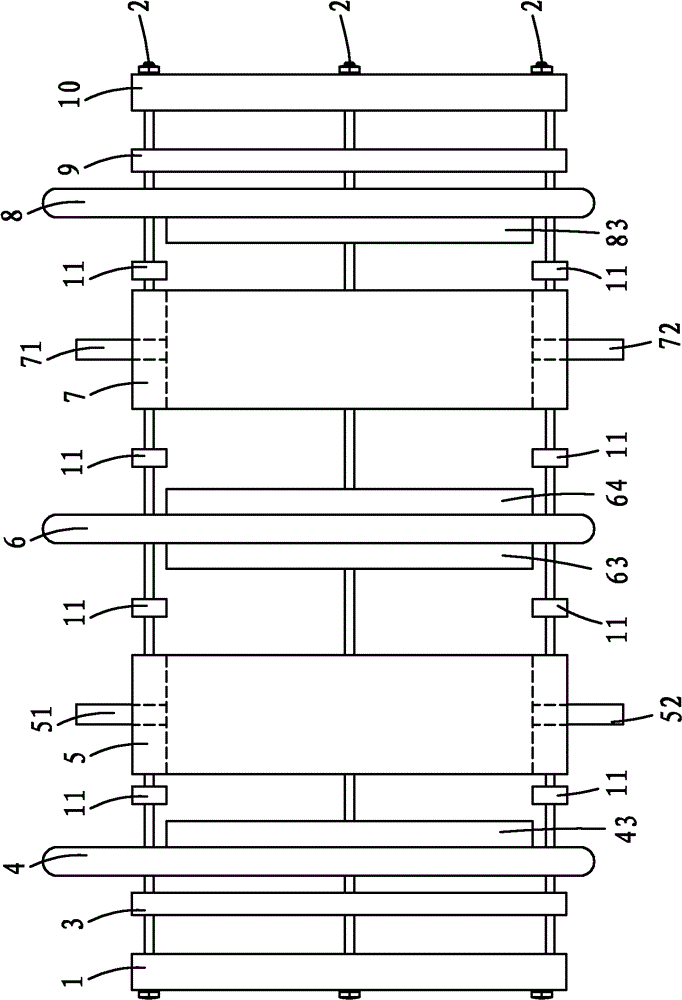

[0017] see figure 1 As shown, a diaphragm-free paired direct electro-oxidation-reduction reactor for activated carbon fiber electrodes includes a first insulating plate 1, and the inner side of the first insulating plate 1 is fixedly connected with a first electrode gasket 3 via bolts 2 in turn. , the first activated carbon fiber terminal electrode 4, the first electrode chamber 5, the activated carbon fiber common electrode 6, the second electrode chamber 7, the second activated carbon fiber terminal electrode 8, the second electrode gasket 9, and the second insulating plate 10; Both sides of the first electrode chamber 5 and the second electrode chamber 7 are provided with sealing rings 11; the upper parts of the first electrode chamber 5 and the second electrode chamber 7 are provided with water outlet pipes (51, 71) and their lower parts are provided with Water inlet pipe (52,72) is arranged.

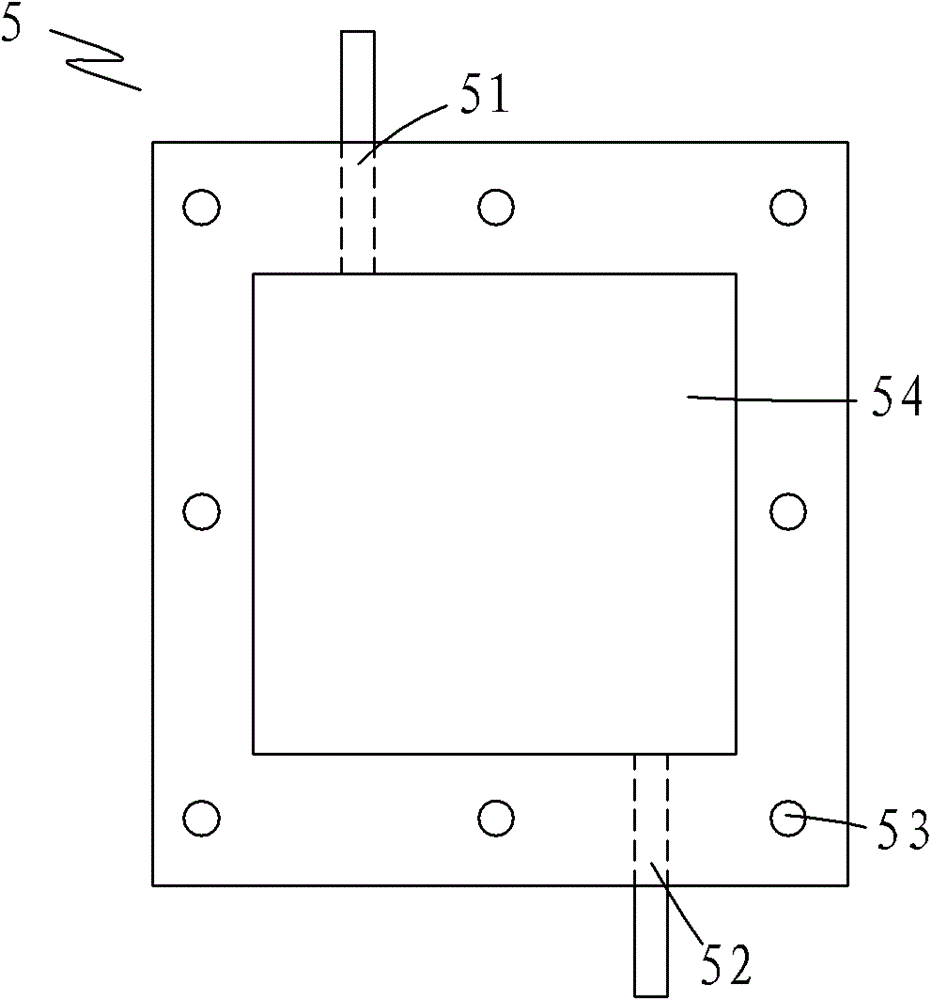

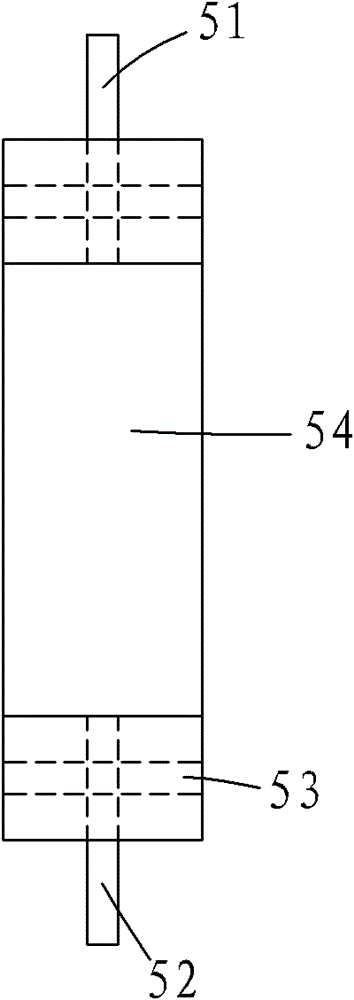

[0018] like Figure 2A and Figure 2B As shown, the upper part of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com