Method for manufacturing battery negative pole piece

A production method and battery negative electrode technology, applied in the direction of alkaline storage battery electrodes, etc., can solve the problems of affecting the hydrogen storage capacity of alloy powder, battery internal pressure, life-span comprehensive performance reduction, and failure to generate potential protection, etc., to achieve improved consistency and extreme The efficiency of sheet production, the reduction of liquid retention in the diaphragm, and the effect of extending cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in combination with specific embodiments and with reference to the accompanying drawings.

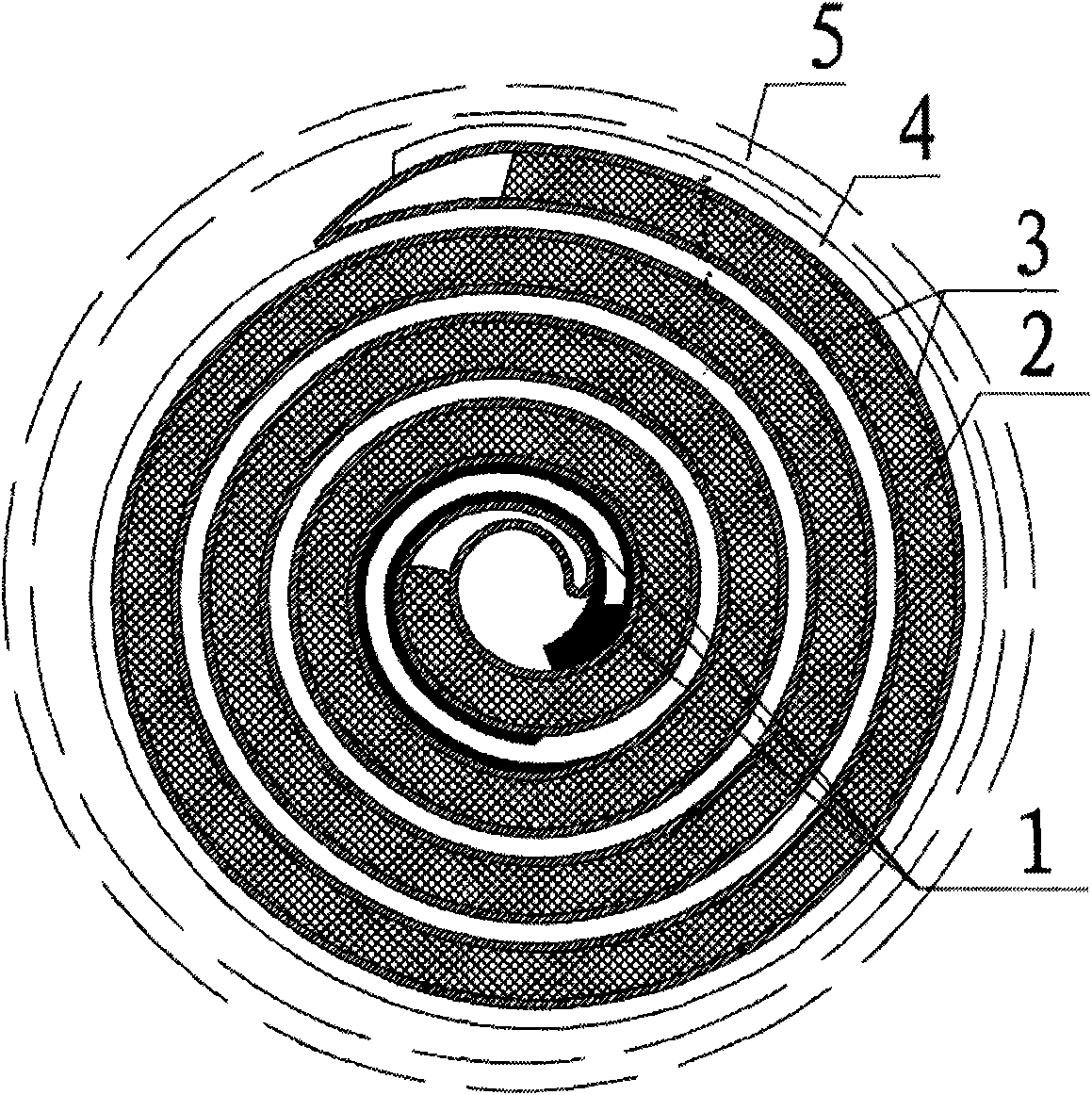

[0025] a kind of like figure 1 In the shown AA-type Ni-MH battery, a small separator 1 is provided at the winding place to prevent short circuit caused by burrs.

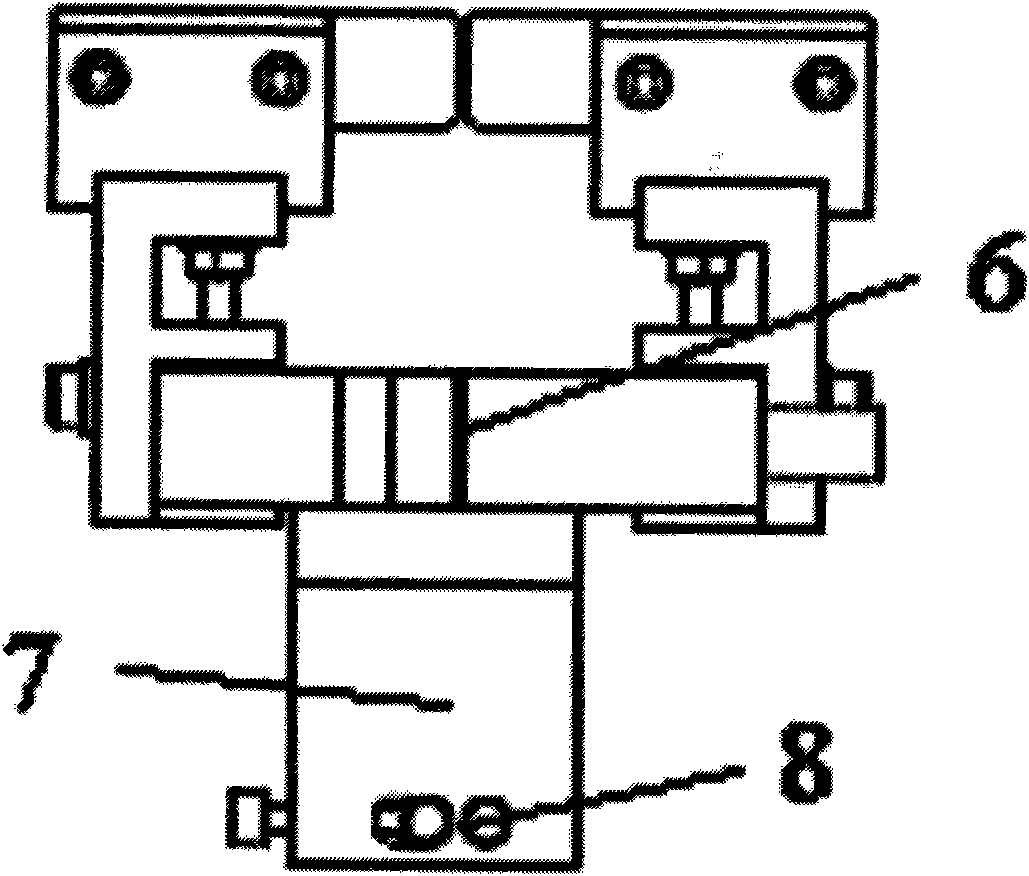

[0026] The method for making the positive plate comprises mixing 93 parts of commercial spherical nickel hydroxide, 5 parts of cobaltous oxide, and 2 parts of additives with 3 parts of CMC aqueous solution and PTFE aqueous solution as a binder to make positive electrode slurry, and then Filled into foamed nickel, dried, rolled and cut into 90mm×43mm×0.70mm, the total amount of active material contained in the positive electrode is 8.0g.

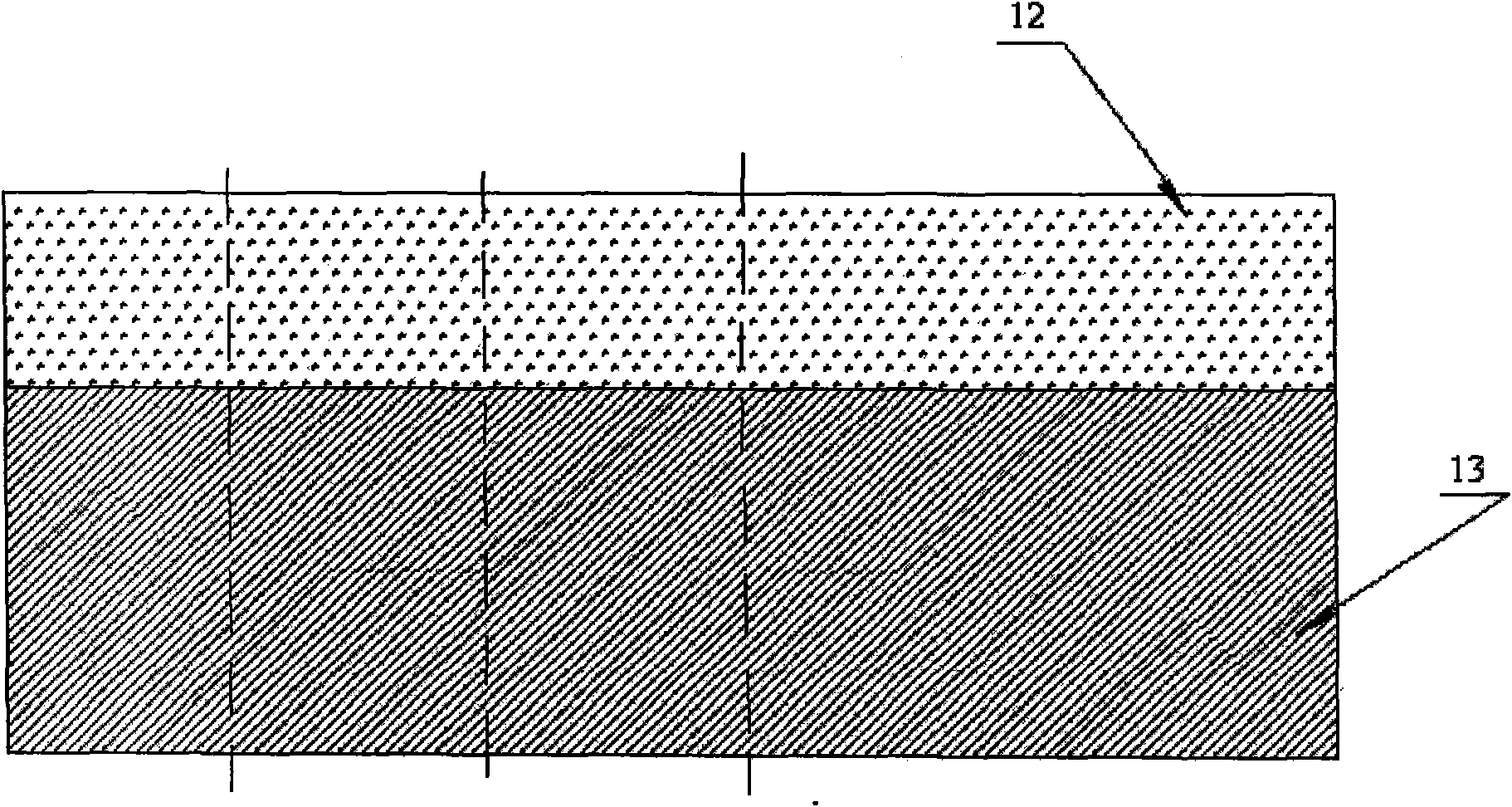

[0027] The manufacturing method of the negative electrode sheet includes preparation of slurry, continuous sizing, cutting, drying, and rolling.

[0028] The preparation of the slurry is to mix the commercialized AB5 hydrogen sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com