Bipolar electrode sheet, bipolar battery contain that electrode sheet, and maintenance and regeneration method thereof

A bipolar electrode and bipolar battery technology, applied in the direction of bipolar electrode, active material electrode, electrolyte/reactant regeneration, etc., can solve the problem of electrolyte leakage, low injection efficiency, and difficult to control the consistent injection volume problems such as the uniformity of the electrolyte distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

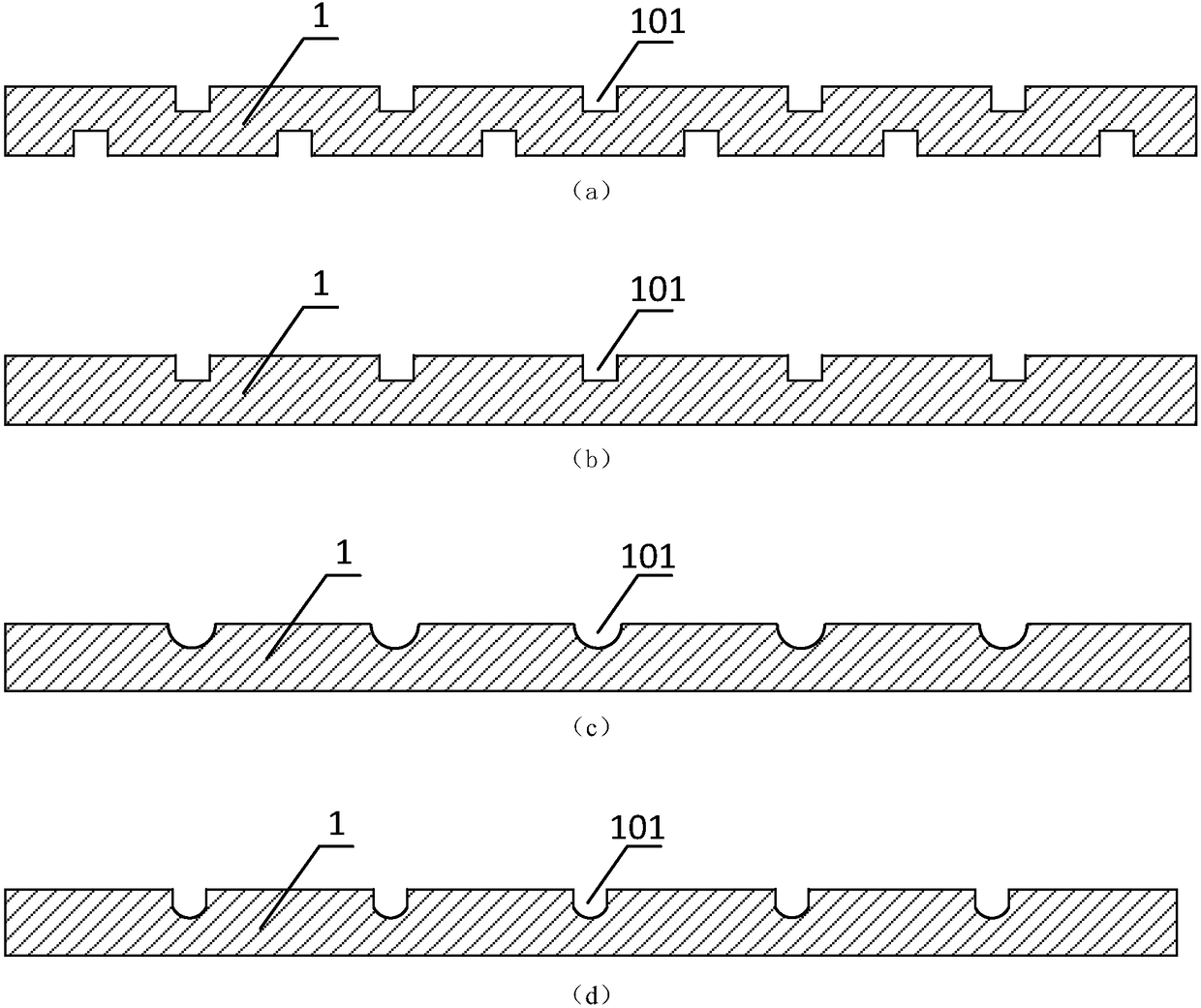

[0082] This example provides several versions of the bipolar plate of the present invention.

[0083] figure 1 is a schematic cross-sectional view of a bipolar plate according to the present invention. Both sides of the bipolar plate 1 are provided with an electrolyte flow channel 101, as shown in figure (a), or, one side of the bipolar plate 1 is provided with an electrolyte flow channel 101, as shown in figure (b) and figure (c) , Figure (d) shown. In this embodiment, the electrolyte flow channel is a concave groove to facilitate the flow of the electrolyte, and the cross section of the groove is square, as shown in Figure (a) and Figure (b); or, the cross section of the groove is semicircular, such as As shown in figure (c); or, the cross section of the groove is U-shaped, as shown in figure (d).

Embodiment 2

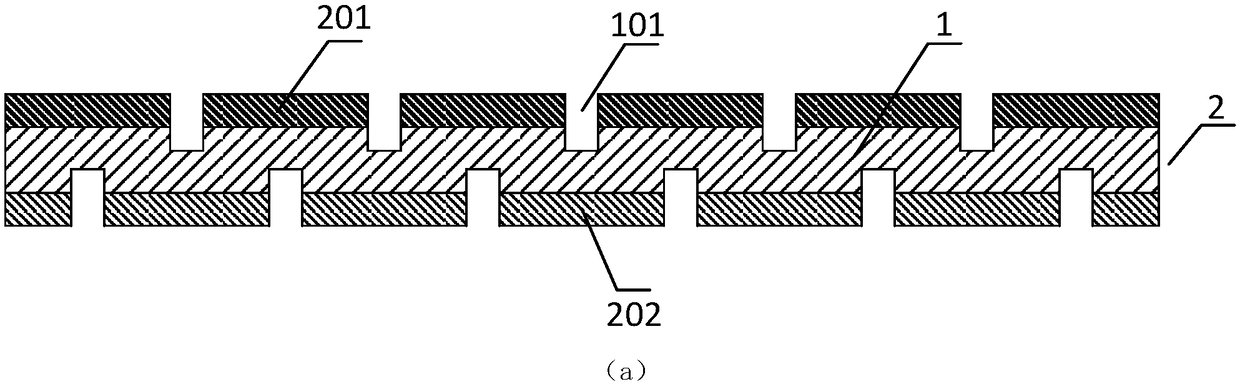

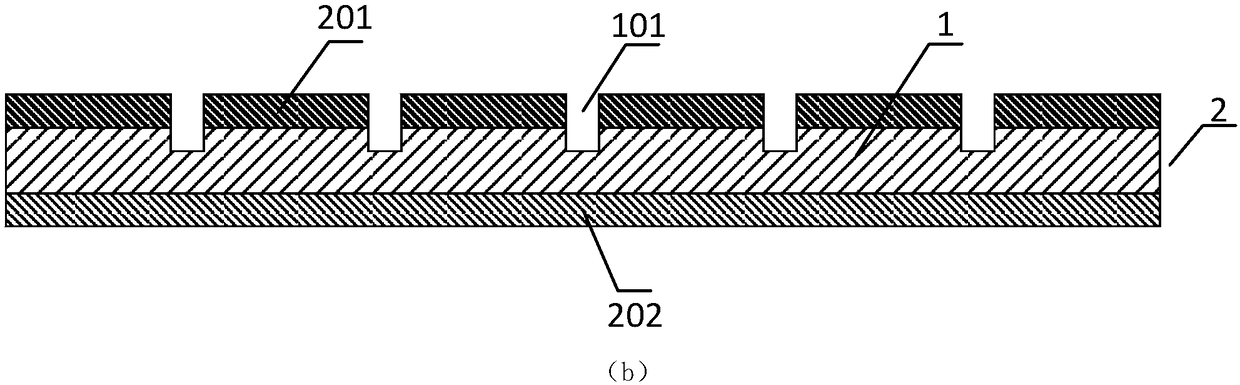

[0085] This example provides several forms of the bipolar electrode sheet of the present invention.

[0086] figure 2 It is a schematic cross-sectional view of a bipolar electrode sheet according to the present invention. On both sides of the bipolar plate 1, a positive electrode material layer 201 and a negative electrode material layer 202 are respectively coated to form a bipolar electrode sheet, figure 2 (a) The two sides of the bipolar plate of the bipolar electrode sheet in the middle are respectively provided with electrolyte flow channels, figure 2 One side of the bipolar plate of the bipolar electrode sheet in (b) is provided with an electrolyte flow channel.

Embodiment 3

[0088] This embodiment provides several forms of the electrolyte channel of the present invention.

[0089] image 3 It is a schematic diagram of the electrolyte channel structure on the surface of the bipolar plate according to the present invention.

[0090] The electrolyte flow channel is a single flow channel, and a liquid port 301 is provided at the end of the single flow channel and communicated with the flow channel, and the electrolyte flows into the single flow channel through the liquid port 301 . When the electrolyte flow channel is a single flow channel, the electrolyte flow channel can be arranged in a straight line or in a curved line, such as image 3 (a) and image 3 (b) shown.

[0091] In order to ensure the wettability of the electrolyte in the electrode material layer, the electrolyte channel is preferably multi-channel. The arrangement of multiple channels can include a main channel 303 and a branch channel 304. The liquid port 301 is located at the end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com