Aqueous fire-proof corrosion-proof paint for steel structure and preparation method thereof

A technology of anti-corrosion coatings and anti-corrosion coatings, applied in the field of coatings, can solve the problems of affecting the fire protection and anti-corrosion effect of steel structures, coating peeling off, high process costs, etc., and achieve good fire protection, improved dispersion, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

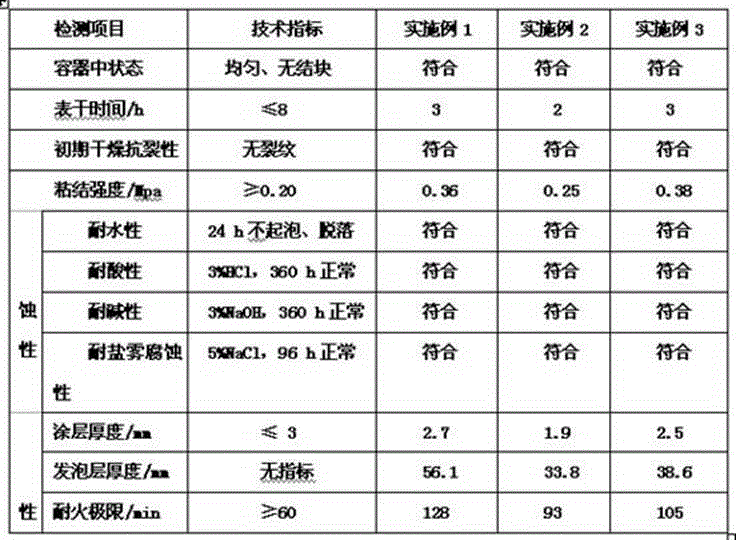

Embodiment 1

[0043] Prepare steel structure fireproof and anticorrosion paint of the present invention according to the composition and mass percentage listed below:

[0044] Silicone acrylic emulsion 10%

[0045] Chlorine Partial Emulsion 14%

[0046] Ammonium polyphosphate 15%

[0047] Melamine 7%

[0048] Pentaerythritol 10%

[0049] Mg-Al type layered double hydroxide 1%

[0050] Modified aluminum hydroxide 3%

[0051] Zinc borate 3%

[0053] Aluminum polyphosphate 3%

[0054] Mica flakes 2%

[0055] Wollastonite powder 3%

[0056] Talc 3%

[0057] Modified Nano Silica 2%

[0058] Auxiliary 3%

[0059] water 17%

[0060] The preparation process of this example is as follows: add water, some additives and powder to the mixer in sequence, stir for 30 minutes at a speed of 700 r / min, and then transfer to a ball mill for grinding until the specified Fineness, then transfer to the agitator, adjust the speed to 600 ...

Embodiment 2

[0062] Prepare steel structure fireproof and anticorrosion paint of the present invention according to the composition and mass percentage listed below:

[0063] Silicone acrylic emulsion 12%

[0065] Polyvinyl acetate emulsion 6%

[0066] Ammonium polyphosphate 12%

[0067] Melamine 7%

[0068] Dipentaerythritol 8%

[0069] Ca-Al type layered double hydroxide 1%

[0070] Modified Magnesium Hydroxide 3%

[0071] Zinc borate 4%

[0072] Zinc Phosphate 4%

[0073] Aluminum polyphosphate 2%

[0074] Barium metaborate 2%

[0075] Flake zinc powder 2%

[0076] Sericite 3%

[0077] Talc 2%

[0078] Expanded Vermiculite 1%

[0079] Modified Nano Titanium Dioxide 2%

[0080] Various additives 3%

[0081] water 20%

[0082] The preparation process of this example is as follows: add water, some additives and powder to the mixer in sequence, stir for 20 minutes at a speed of 800 r / min, and then transfer ...

Embodiment 3

[0084] Prepare steel structure fireproof and anticorrosion paint of the present invention according to the composition and mass percentage listed below:

[0085] Pure acrylic emulsion 10%

[0086] Chlorine partial emulsion 15%

[0087] Ammonium polyphosphate 12%

[0088] Melamine 6%

[0089] Pentaerythritol 8%

[0090] Mg-Al type layered double hydroxide 2%

[0091] Modified aluminum hydroxide 4%

[0092] Zinc borate 4%

[0093] Zinc Phosphate 3%

[0094] Aluminum polyphosphate 3%

[0095] Aluminum powder 1%

[0096] Wollastonite powder 3%

[0097] Talc 3%

[0098] Vitrified Beads 2%

[0099] Modified Nano Silica 2%

[0100] Various additives 2%

[0101] water 20%

[0102] The preparation process of this example is as follows: add water, some additives and powder to the mixer in sequence, stir for 30 minutes at a speed of 800 r / min, and then transfer to a ball mill for grinding until the specified Fineness, then transfer to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com