Fireproof guardrail

A technology for guardrails and glass panels, applied in fire prevention, building components, building structures, etc., can solve the problems of material waste, high cost, time-consuming and labor-intensive, etc., and achieve the effects of cost reduction, compact structure, and good aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

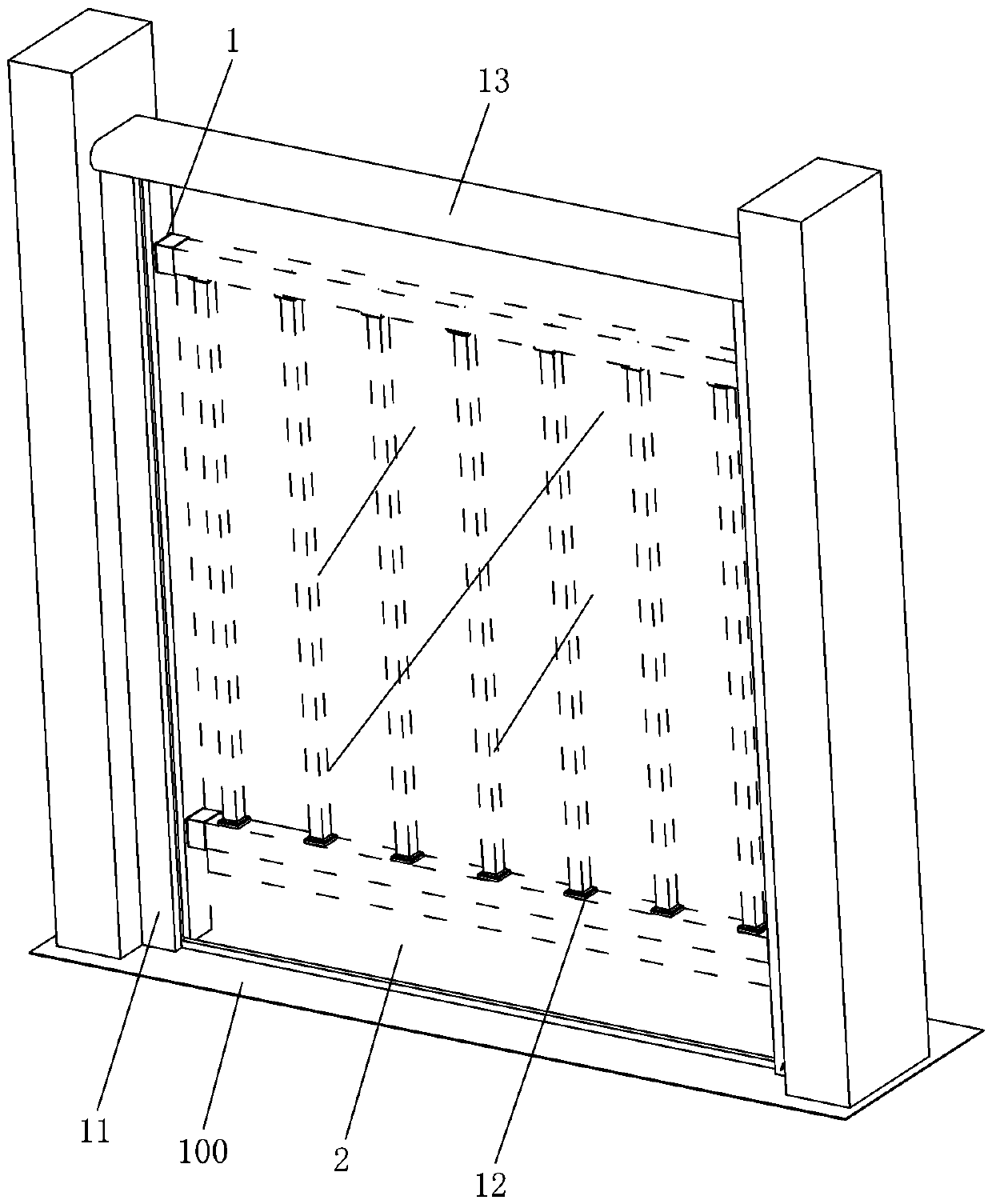

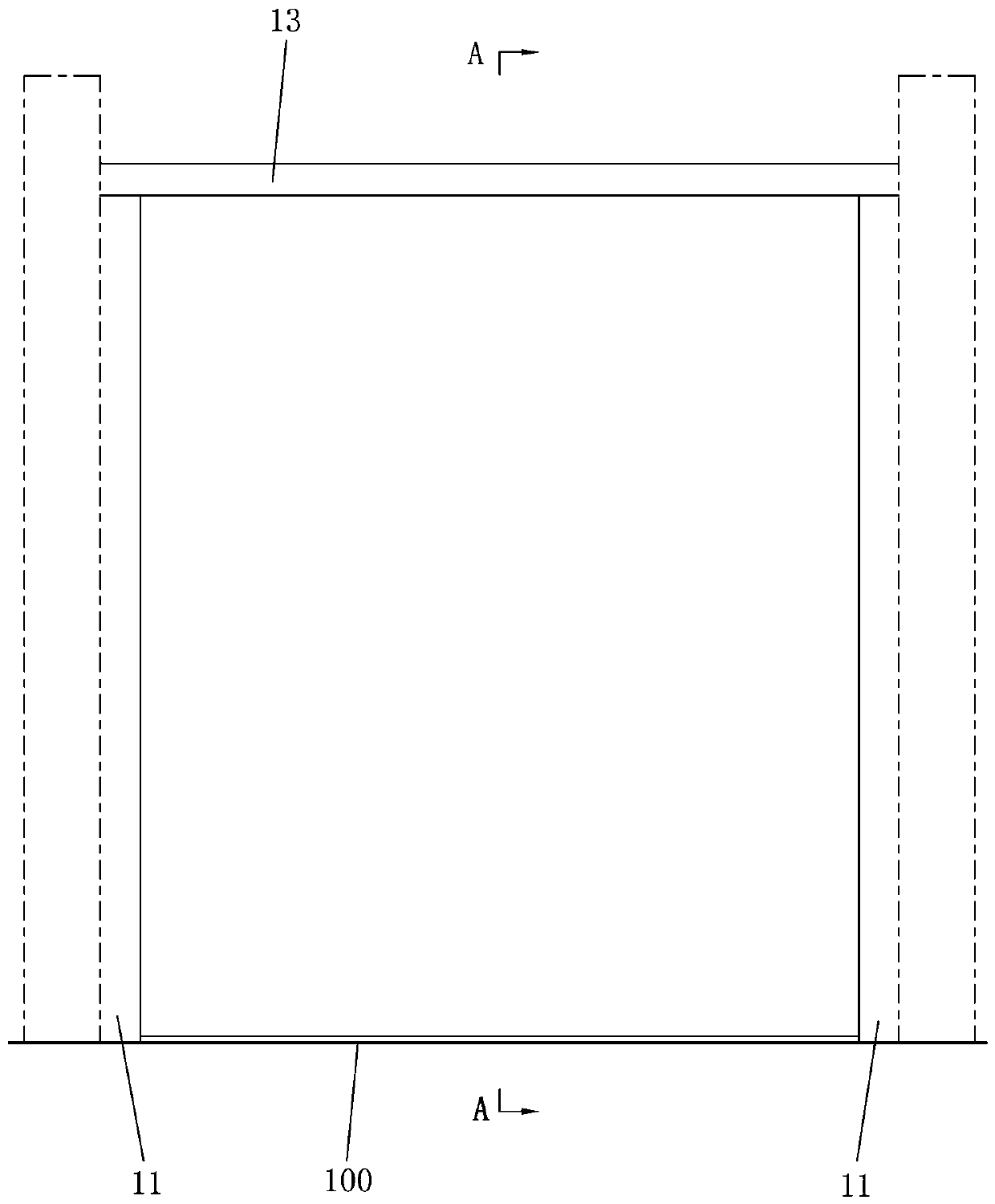

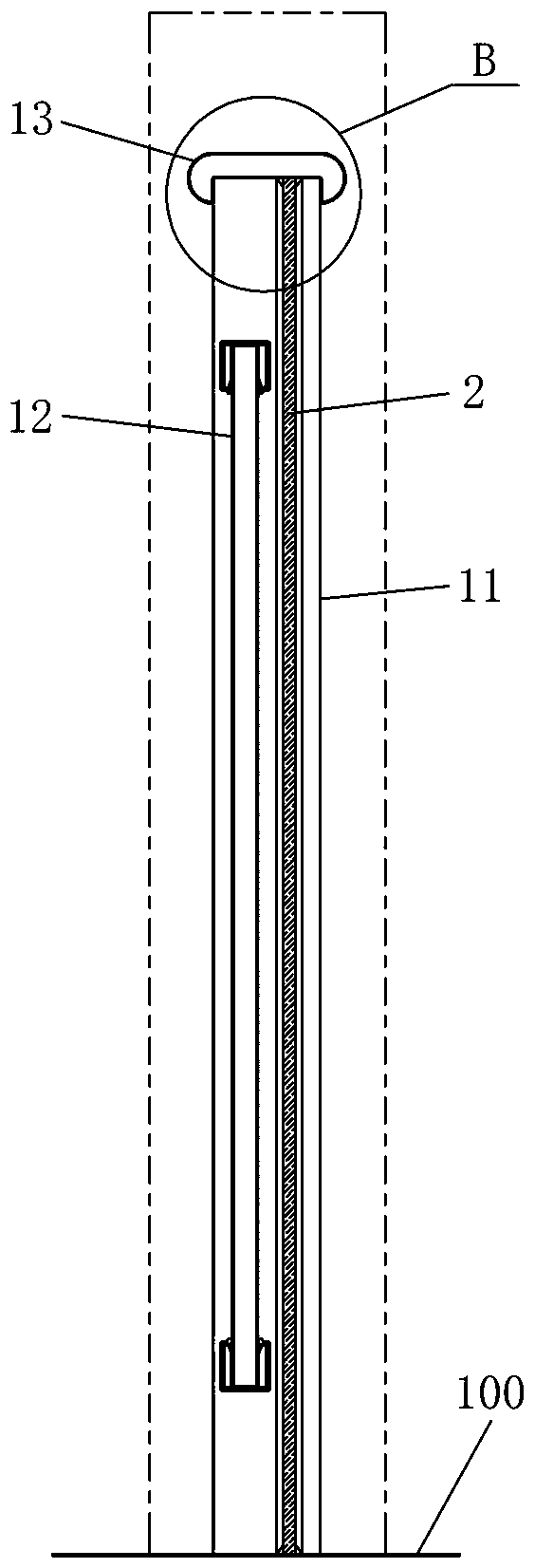

[0026] Such as Figure 1 to Figure 3 As shown, the fire protection barrier of this embodiment includes a guardrail body 1 installed on the installation bottom surface 100. The guardrail body 1 has two uprights 11 and a railing assembly 12 installed between the two uprights 11. One side of the guardrail body 1 A fireproof glass panel 2 is installed. The fireproof guardrail can simultaneously take into account fireproof and protective functions, and because the fireproof glass plate 2 is directly installed on the guardrail body 1, it has a compact structure, good aesthetics, and can save materials and reduce costs.

[0027] In this embodiment, the fireproof glass plate 2 is installed on two upright columns 11, which is beneficial to improve installation convenience, compact structure, aesthetic appearance and stability after installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com