Fireproof and corrosion-resistant coating applied to steel structures

A technology for anti-corrosion coatings and steel structures, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of low thermal insulation capacity, limited use, and increased steel structure load, so as to improve fire-resistant thermal insulation performance while taking into account Fire resistance, effect of improving fire resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of modified potassium titanate whisker is:

[0021] Add potassium titanate whiskers to 3wt% maleic acid solution for ultrasonic dispersion, heat up to 80°C, then add nano-titanium dioxide and aluminate coupling agent, stir for 10 hours, and then centrifuge and vacuum dry.

[0022] The mass ratio of potassium titanate whiskers to aluminate coupling agent is 25:1, and the mass ratio of potassium titanate whiskers to nano titanium dioxide is 6:1.

Embodiment 2

[0024] The preparation method of modified potassium titanate whisker is:

[0025] Add potassium titanate whiskers to 6wt% maleic acid solution for ultrasonic dispersion, heat up to 90°C, then add nano-titanium dioxide and aluminate coupling agent, stir for 5 hours, and then centrifuge and vacuum dry.

[0026] The mass ratio of potassium titanate whiskers to aluminate coupling agent is 35:1, and the mass ratio of potassium titanate whiskers to nano titanium dioxide is 2:1.

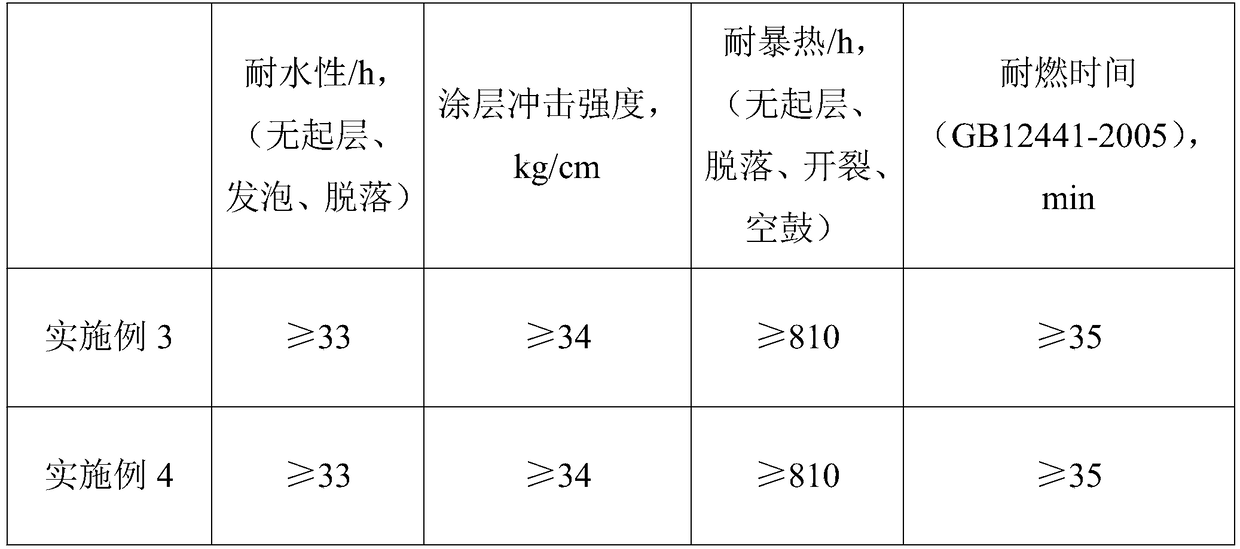

Embodiment 3

[0028] A fireproof and anticorrosion coating for steel structures, comprising the following components in parts by weight:

[0029] 50 parts of acrylic emulsion, 20 parts of dibutyl phthalate, 6 parts of ammonium polyphosphate, 7 parts of sorbitol, 12 parts of aluminum hydroxide, 0.6 parts of sodium hexametaphosphate wetting agent, 0.5 parts of water-based acrylate copolymer, 12 parts of anti-corrosion filler and 26 parts of the modified potassium titanate whisker of Example 1. The anti-corrosion filler is a mixture of aluminum polyphosphate, zinc borate and barium metaborate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com