Preparation method of fire-resistant and heat-insulation sewing thread

A sewing thread and fire-resistant technology, which is applied in the field of preparation of fire-resistant and heat-insulating sewing thread, can solve the problems of insufficient fire-resistant and heat-insulating performance of sewing thread, and achieve the effects of increasing diversity, improving quality, and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

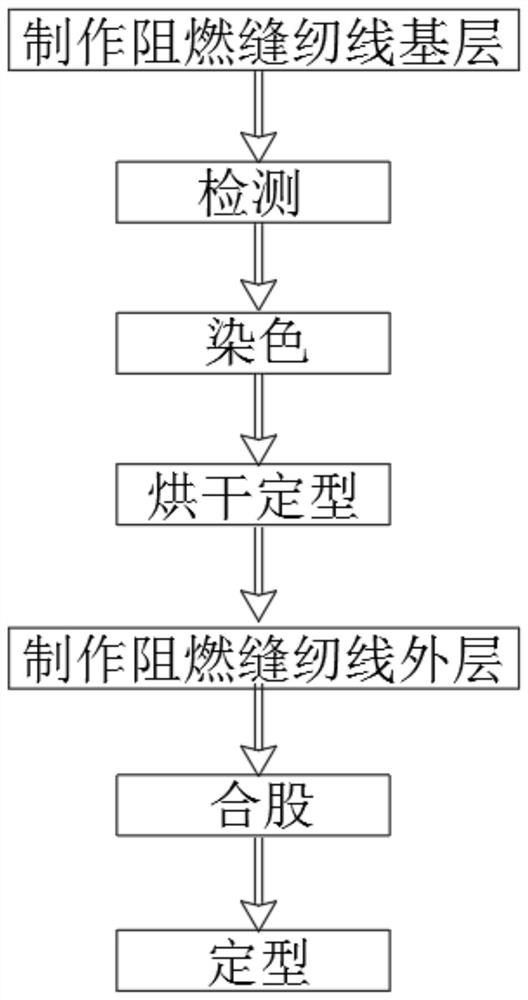

[0032] refer to figure 1 , a preparation method of fire-resistant and heat-insulating sewing thread, comprising the following steps:

[0033] S1: Make the base layer of flame-retardant sewing threads, and use water-soluble polyvinyl alcohol fibers as raw materials to make sewing threads of different yarn counts and thicknesses;

[0034] S2: Inspection, random inspection of the sewing thread, testing its elongation at break, the elongation at break of the sewing thread is between 50-80% is qualified, otherwise it is unqualified, and the unqualified rate is greater than 8%, then discuss whether the analysis process has problem, and to detect it, through the detection steps to ensure that the elongation at break of the sewing thread is within the acceptable range and improve its quality;

[0035] S3: dyeing, the sewing thread is continuously fed, and the sewing thread is dipped in a coloring solution containing ultraviolet curable resin, photopolymerization initiator, pigment an...

Embodiment 2

[0043] S1: Make the base layer of flame-retardant sewing threads, and use water-soluble polyvinyl alcohol fibers as raw materials to make sewing threads of different yarn counts and thicknesses;

[0044] S2: Inspection, random inspection of sewing thread, testing its elongation at break, the elongation at break of sewing thread is between 50-80% is qualified, otherwise it is unqualified, if the unqualified rate is greater than 10%, discuss whether the analysis process has problem, and to detect it, through the detection steps to ensure that the elongation at break of the sewing thread is within the acceptable range and improve its quality;

[0045] S3: dyeing, the sewing thread is continuously fed, and the sewing thread is dipped in a coloring solution containing ultraviolet curable resin, photopolymerization initiator, pigment and organic solvent for dyeing treatment;

[0046] S4: Drying and shaping, high temperature drying and shaping of the sewing thread;

[0047] S5: Make...

Embodiment 3

[0053] S1: Make the base layer of flame-retardant sewing threads, and use water-soluble polyvinyl alcohol fibers as raw materials to make sewing threads of different yarn counts and thicknesses;

[0054] S2: Inspection, random inspection of sewing thread, testing its elongation at break, the elongation at break of sewing thread is between 55-70% is qualified, otherwise it is unqualified, if the unqualified rate is greater than 10%, discuss whether the analysis process has problem, and to detect it, through the detection steps to ensure that the elongation at break of the sewing thread is within the acceptable range and improve its quality;

[0055] S3: dyeing, the sewing thread is continuously fed, and the sewing thread is dipped in a coloring solution containing ultraviolet curable resin, photopolymerization initiator, pigment and organic solvent for dyeing treatment;

[0056] S4: Drying and shaping, high temperature drying and shaping of the sewing thread;

[0057] S5: Make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com