A kind of fireproof coating and preparation method thereof

A technology of fire-resistant coatings and raw materials, applied in fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as property loss, application restrictions, and endangering the lives of the people, and achieve enhanced flame-retardant effects and thermal stability The effect of good and excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

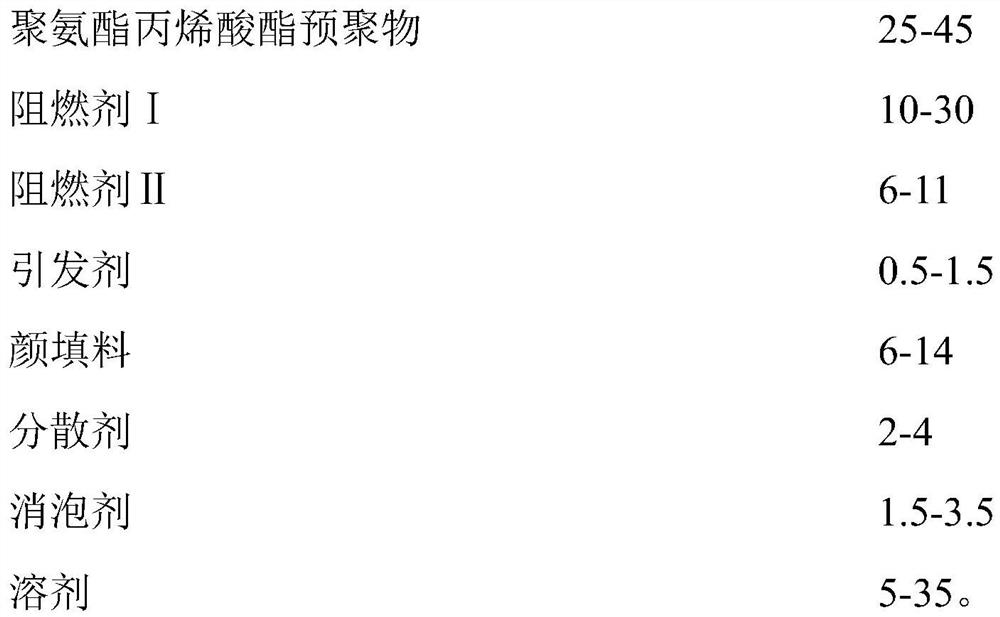

[0022] The invention provides a kind of fireproof coating, and by weight percentage, described coating comprises following raw material:

[0023]

[0024] The raw materials for the preparation of the urethane acrylate prepolymer include isocyanate, acrylate monomers, polymerization inhibitors, and catalysts; under the conditions of nitrogen protection and stirring, the isocyanate and the catalyst are mixed uniformly, and the temperature is raised to 45-55°C, keep warm for 1.5-2h, then raise the temperature to 65-75°C, add a polymerization inhibitor to the mixture after reaching the corresponding temperature, stir well and add the acrylate monomer to the mixture dropwise, controlled at 1- The dropwise addition is completed within 1.5 hours, stirred evenly and kept warm for 2.5-3 hours, and then the temperature of the reaction system is lowered to room temperature to obtain the polyurethane acrylate prepolymer, wherein the isophorone diisocyanate and / or toluene Diisocyanate; ...

Embodiment 2

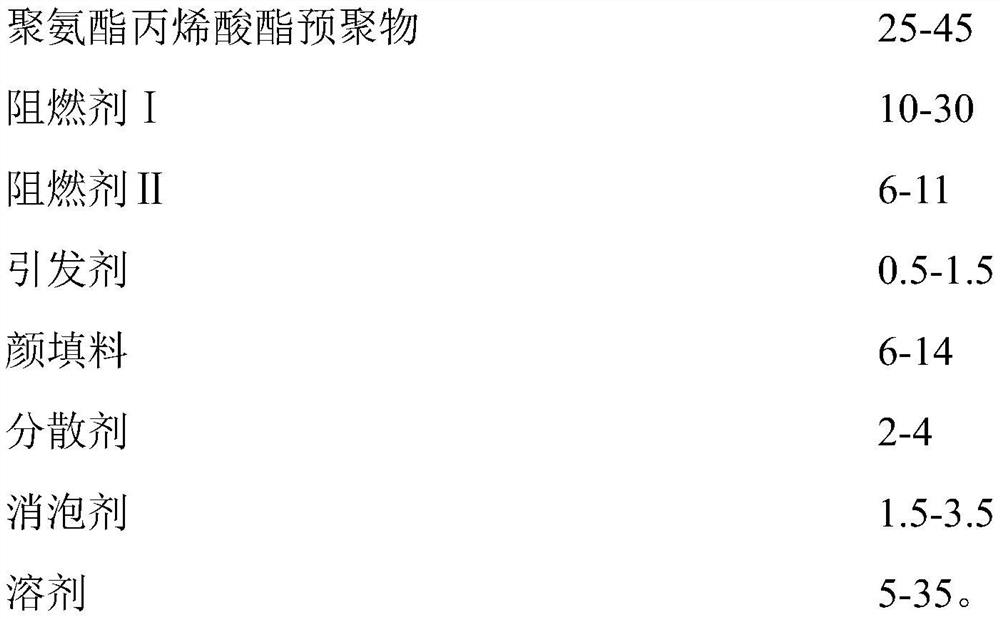

[0035] On the basis of embodiment 1, present embodiment 2 is as a preferred embodiment of the present invention, a kind of fireproof coating, by weight percentage, comprises following raw material:

[0036]

[0037] Wherein, the molar ratio of the said propioloyl chloride to the pentabromophenol is 3:1, the molar ratio of the bromine-free phenol acrylic acid ester to the bromine elemental substance in the bromine water is 2:3, and the ammonium polyphosphate , red phosphorus and aluminum hydroxide are 2:3:3.5, and the preparation method of the fireproof coating is the same as in Example 1.

Embodiment 3

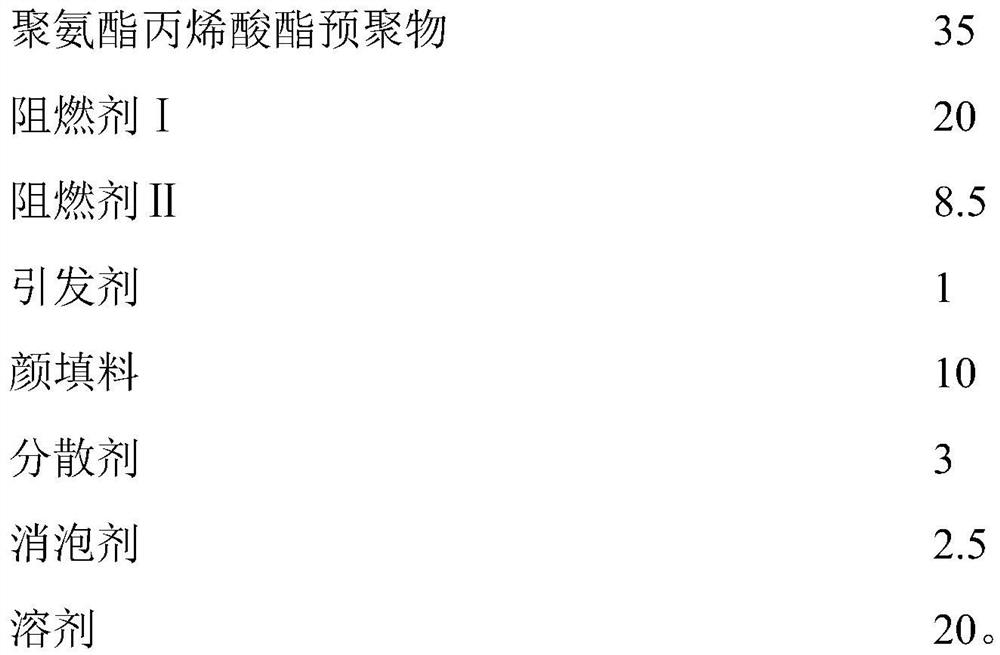

[0039] On the basis of embodiment 1, present embodiment 3 is as a preferred embodiment of the present invention, a kind of fireproof coating, by weight percentage, comprises following raw material:

[0040]

[0041] Wherein, the molar ratio of the propioloyl chloride to the pentabromophenol is 3:2, the molar ratio of the bromine-free phenol acrylic acid ester to the bromine element in the bromine water is 1:2, and the ammonium polyphosphate, red The weight percent of phosphorus and aluminum hydroxide is 1:2:2, and the preparation method of described fireproof coating is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com