Online weaving coating technology for glass fiber base cloth

A coating process, glass fiber-based technology, applied in the field of online weaving and coating process of glass fiber base cloth, can solve the problems of low production efficiency, long time-consuming, troublesome operation, etc., to improve production efficiency, improve fire resistance and heat insulation, The effect of saving equipment cost and production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

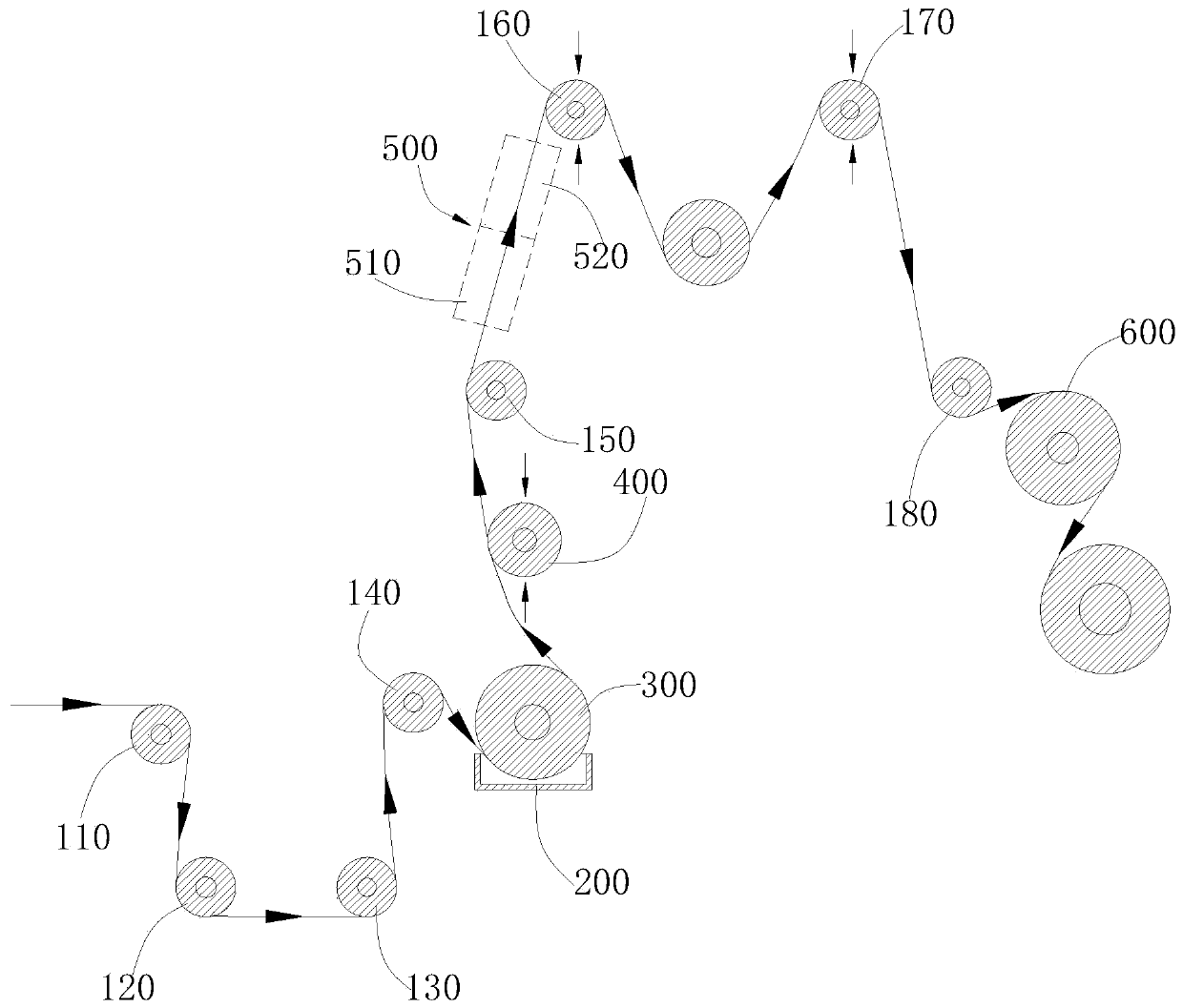

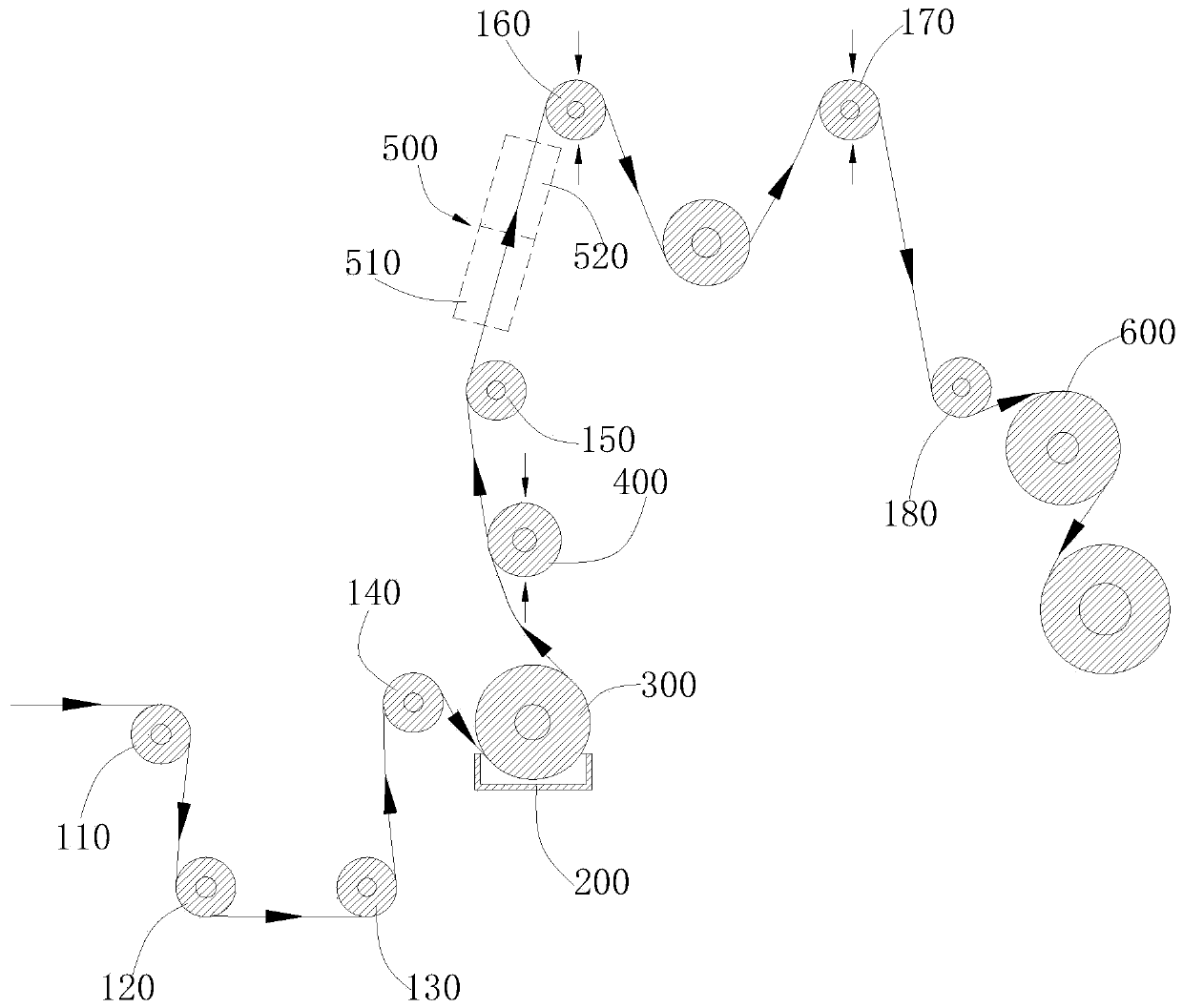

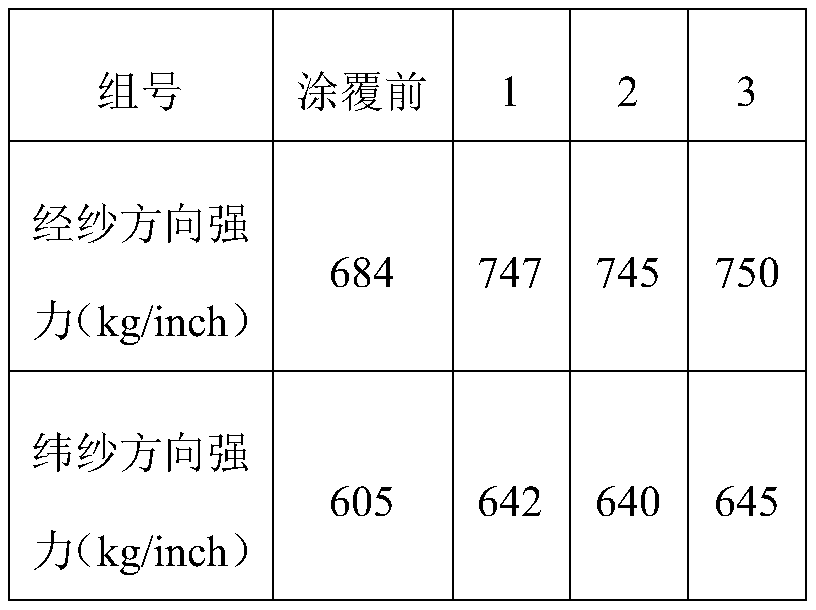

[0023] This embodiment provides an online weaving and coating process for glass fiber base cloth, which includes the following steps: impregnating the woven cloth with the pretreatment liquid while passing through the feeding roller 300, and then extruding it through the extrusion roller 400 , and then heated and dried in the heating and drying zone 500, and then coiled and formed to obtain the glass fiber base cloth; the raw materials of the pretreatment liquid include penetrating agent, silane coupling agent, polyurethane with a concentration of 30-35% and pretreatment Treat the aqueous dispersion; control the concentration of the pretreatment liquid to 4-5%; control the speed of the loom to 0.5-1m / min; the fabric passes through the first heating and drying zone 510 and the second heating and drying zone 520 in sequence; The temperature of the first heating and drying zone 510 is 90-100°C; the temperature of the second heating and drying zone 520 is 75-90°C.

Embodiment 2

[0025] This embodiment provides an online weaving and coating process for glass fiber base cloth, which includes the following steps: impregnating the woven cloth with the pretreatment liquid while passing through the feeding roller 300, and then extruding it through the extrusion roller 400 , and then heated and dried in the heating and drying zone 500, and then coiled and formed to obtain the glass fiber base cloth; the raw materials of the pretreatment liquid include penetrating agent, silane coupling agent, polyurethane with a concentration of 33-38% and pretreatment Treat the aqueous dispersion; control the concentration of the pretreatment liquid to 4.5-5.5%; control the speed of the loom to 1-1.5m / min; the fabric passes through the first heating and drying zone 510 and the second heating and drying zone 520 in sequence; The temperature of the first heating and drying zone 510 is 90-105°C; the temperature of the second heating and drying zone 520 is 80-95°C.

Embodiment 3

[0027] This embodiment provides an online weaving and coating process for glass fiber base cloth, which includes the following steps: impregnating the woven cloth with the pretreatment liquid while passing through the feeding roller 300, and then extruding it through the extrusion roller 400 , and then heated and dried in the heating and drying zone 500, and then coiled and formed to obtain the glass fiber base cloth; the raw materials of the pretreatment liquid include penetrating agent, silane coupling agent, polyurethane with a concentration of 35-40% and pretreatment Treat the aqueous dispersion; control the concentration of the pretreatment liquid to 5-6%; control the speed of the loom to 1.5-2m / min; the fabric passes through the first heating and drying zone 510 and the second heating and drying zone 520 in sequence; The temperature of the first heating and drying zone 510 is 100-115°C; the temperature of the second heating and drying zone 520 is 85-105°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com