Method for preparing carbon material with high specific surface area by using metallic organic framework material as template

A metal-organic framework and high specific surface area technology, which is applied in the field of preparing high specific surface area carbon materials, can solve the problems of difficult structure control, narrow application range, and single pore size, and achieve the effect of easy operation, simple equipment, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

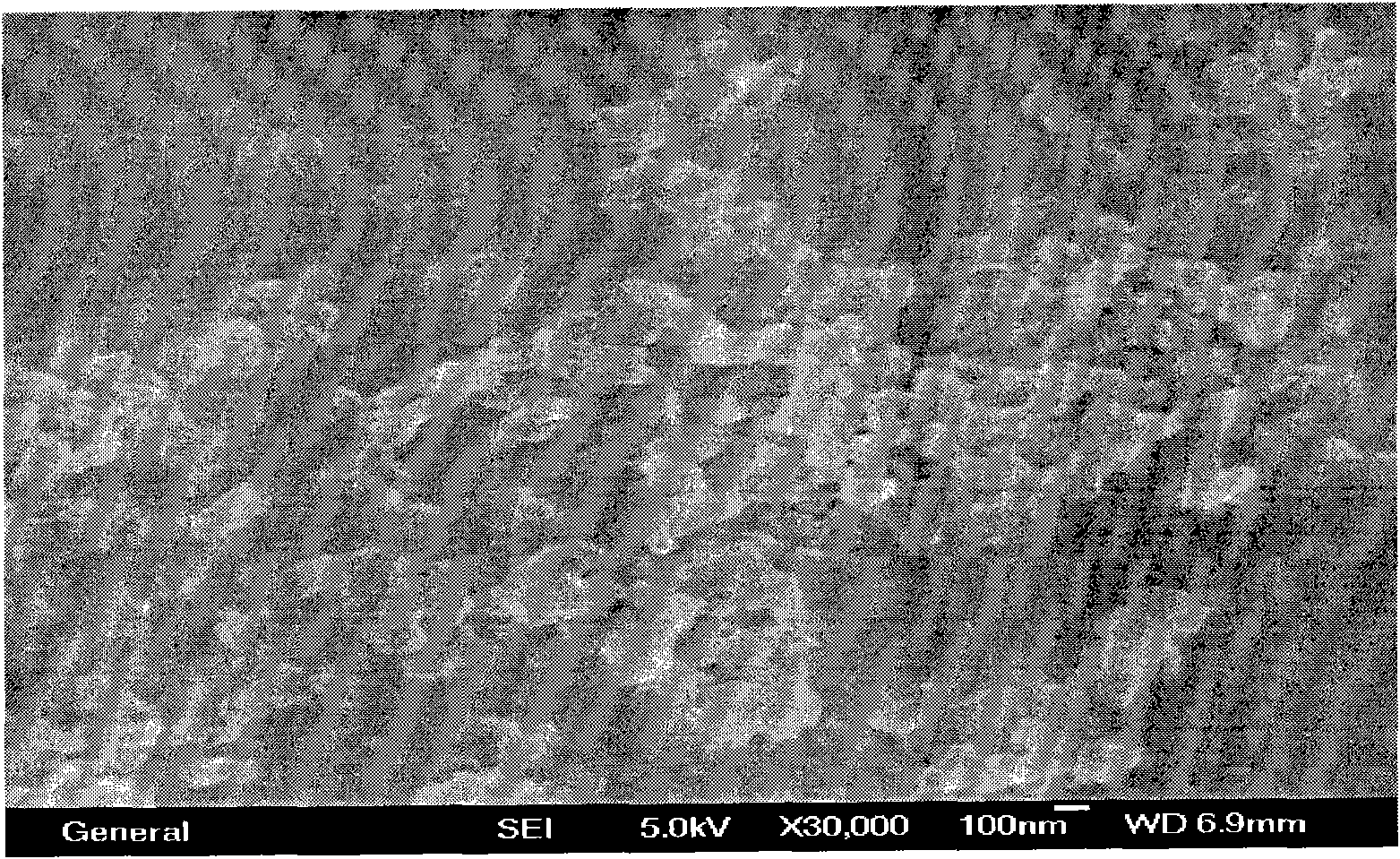

[0043] Using metal-organic framework material Y (BTC) as a template and organic furfuryl alcohol (FA) as a carbon source, high-quality porous carbon materials were prepared by high-temperature carbonization.

[0044] The metal element in Y (BTC) is yttrium (Y), and the coordinated organic compound is trimesic acid (BTC). The preparation method of this substance is to put yttrium nitrate and trimesic acid in the ratio of 1:1 Into ethanol solution, crystallization at 85°C for 12 hours. Soak crystal Y (BTC) in methanol, the mass ratio of crystal to methanol is 1:5, stir at room temperature for 24 hours, filter, remove methanol, repeat the above soaking, stirring, and filtration process 3 times, and put the final product at 60°C Let dry for 12 hours. The obtained product was heated to 150°C under vacuum, and kept at this temperature for 12 hours, then cooled down to room temperature naturally, added carbon source furfuryl alcohol (FA), stopped vacuuming, and allowed furfuryl alco...

Embodiment 2

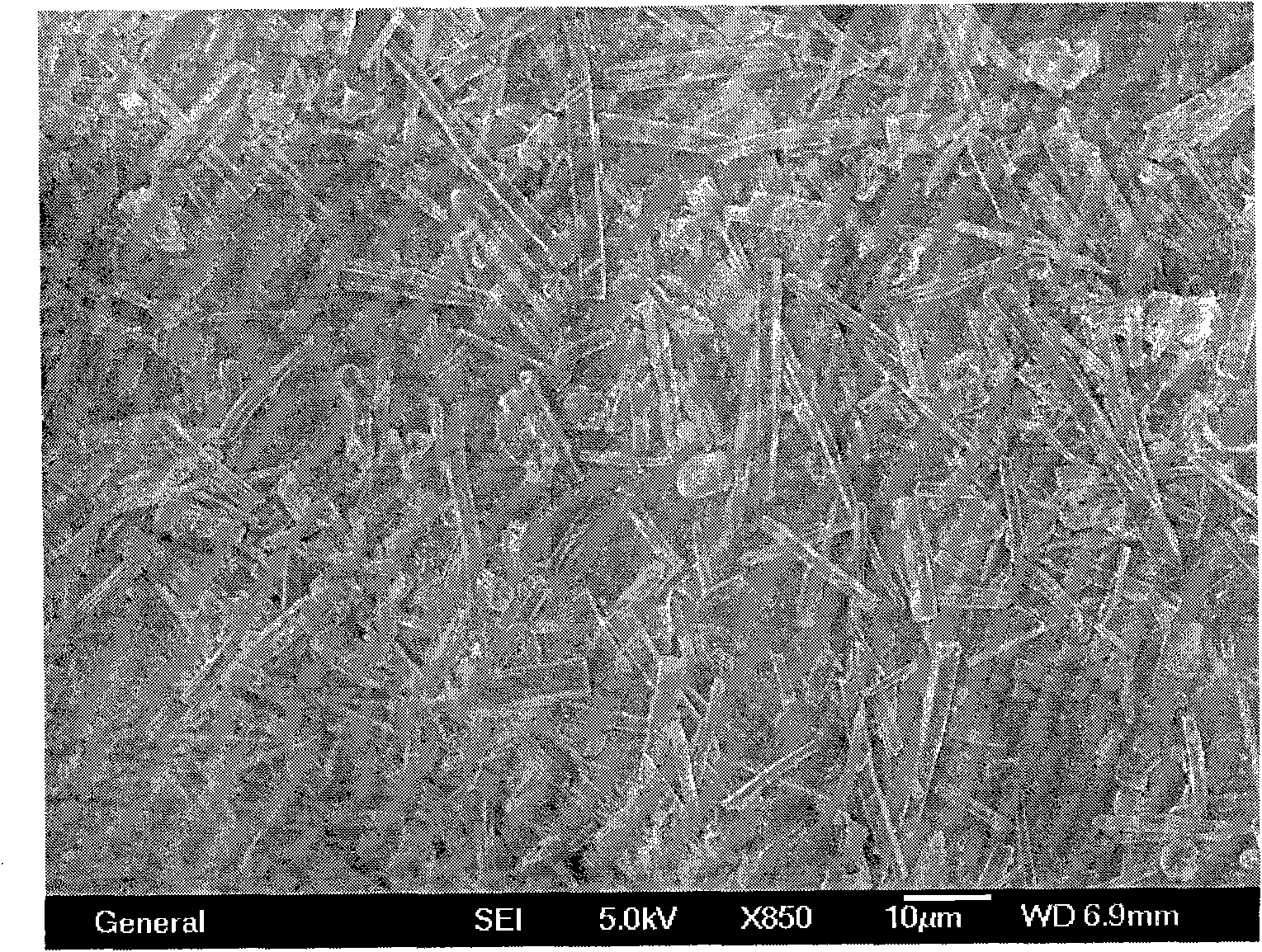

[0046] The main method is the same as that in Example 1, except that the carbonization process of the carbon source / template composite has a different heating program: heating from room temperature to 80°C at a heating rate of 2°C / min, and keeping at 80°C for 24 hours, and heating at 2°C Heating from 80°C to 150°C at a heating rate of 2°C / min, keeping at 150°C for 12 hours, heating at a heating rate of 2°C / min from 150°C to 300°C, and keeping at 300°C for 4 hours, then Heating from 300°C to 800°C at a heating rate of 5°C / min, and maintaining it for 6 hours, and then naturally cooling to room temperature. The specific surface area of the carbon material obtained in this example is 1500m 2 / g.

Embodiment 3

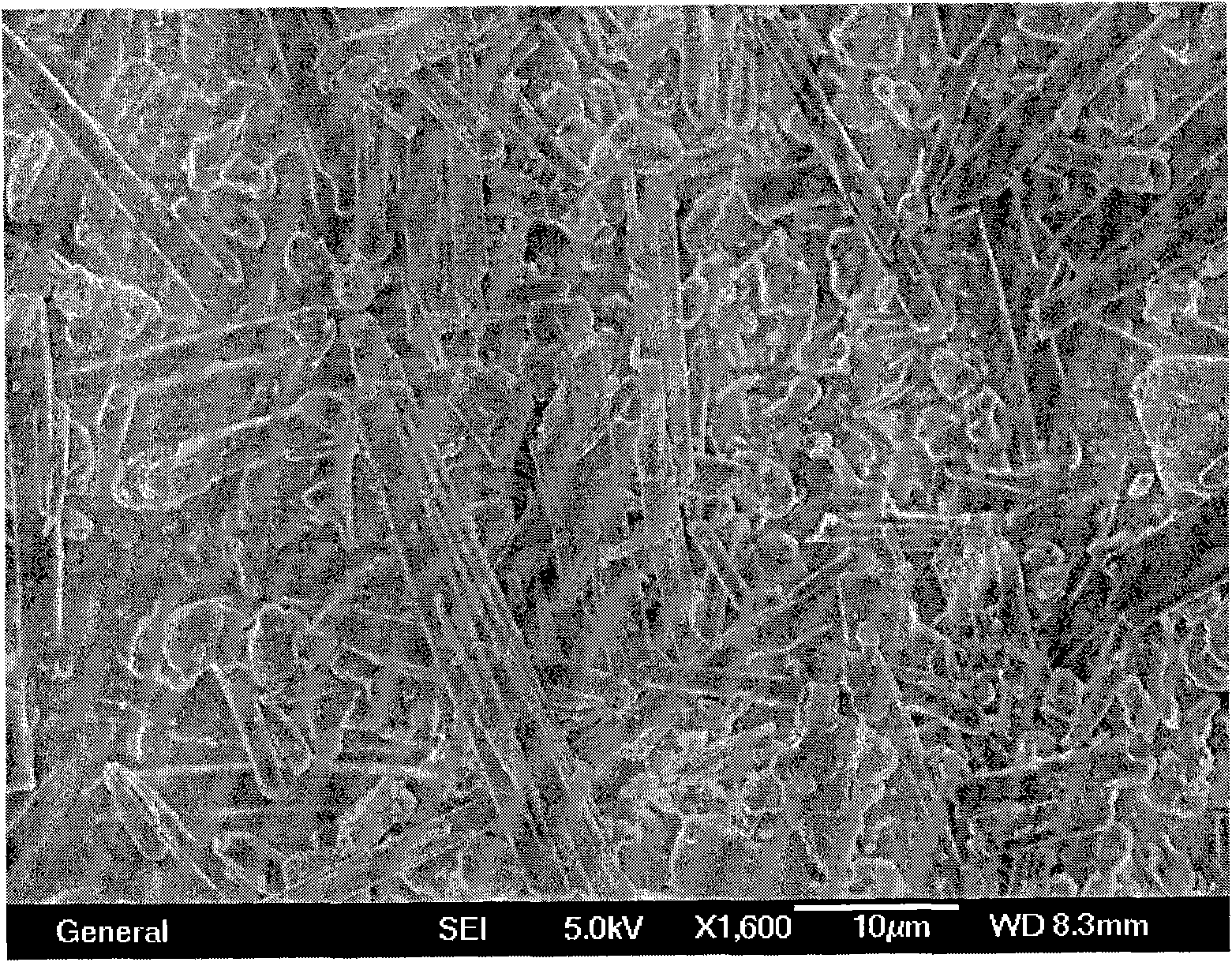

[0048] The main method is the same as that in Example 1, except that the carbonization process of the carbon source / template composite has a different heating program: heating from room temperature to 80°C at a heating rate of 2°C / min, and keeping at 80°C for 24 hours, and heating at 2°C Heating from 80°C to 150°C at a heating rate of 2°C / min, keeping at 150°C for 12 hours, heating at a heating rate of 2°C / min from 150°C to 300°C, and keeping at 300°C for 4 hours, then Heated from 300°C to 1000°C at a heating rate of 5°C / min, and kept for 5 hours, and then naturally cooled to room temperature. The specific surface area of the carbon material obtained in this example is 1800m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com