Low-thermal-conductivity flame-retardant fireproof silicone rubber composite material and preparation method thereof

A composite material and silicone rubber technology, which is applied in the field of low thermal conductivity, flame-retardant and fire-resistant silicone rubber composite materials and its preparation, can solve problems such as poor adhesion of support materials, poor cross-linking of silicone rubber, and reduced mechanical properties of silicone rubber. , to achieve the effects of reducing impact, improving dispersion, and excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

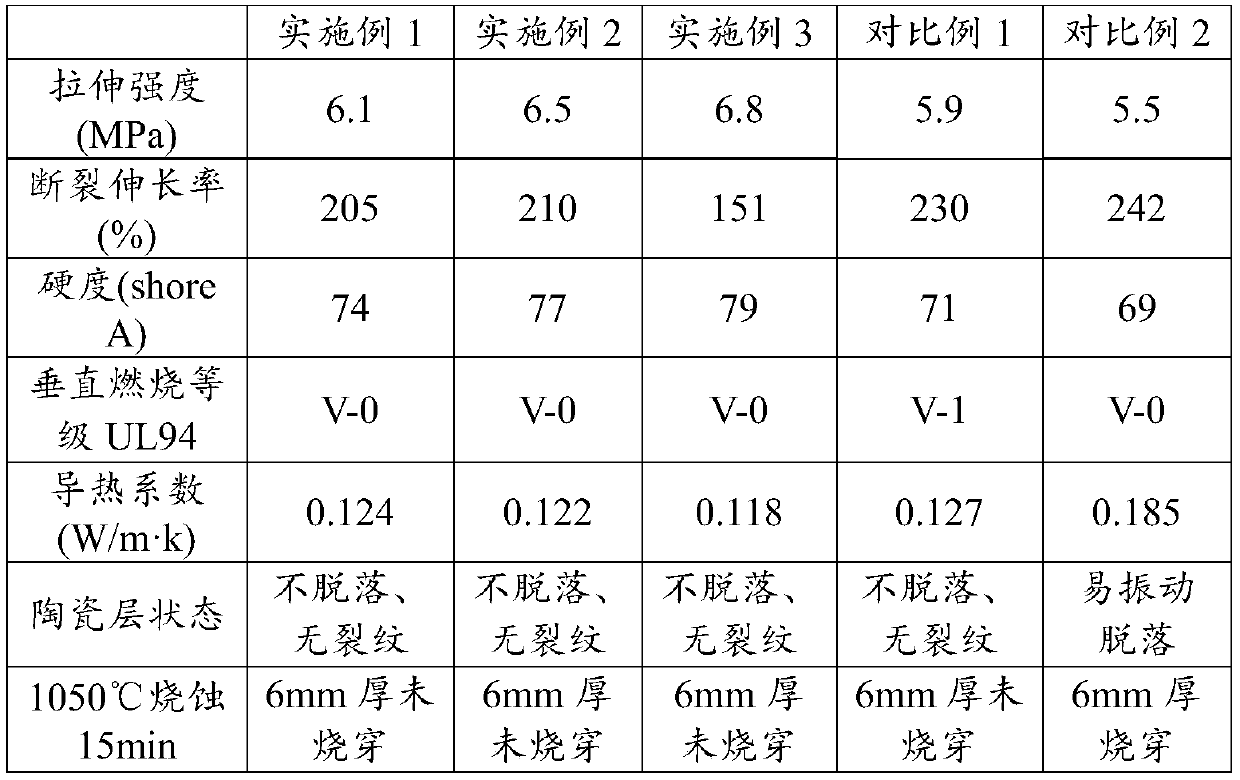

Examples

preparation example Construction

[0047] The present invention provides a method for preparing a low thermal conductivity, flame retardant and fireproof silicone rubber composite material described in the above technical solution, comprising the following steps:

[0048] Methyl vinyl silicone rubber, methyl vinyl phenyl silicone rubber, hydrophobic silica airgel powder, metal oxide powder, flux, hydroxyl silicone oil, organic-inorganic compound flame retardant, antioxidant After the agent is mixed, banbury, then add fumed white carbon black, cross-linking auxiliary agent, banbury again, and get the mixed rubber;

[0049] vulcanizing the mixed rubber by radiation to obtain vulcanized silicone rubber;

[0050] The vulcanized silicone rubber is treated at a constant temperature of 65-75° C. for 25-35 minutes to obtain a low thermal conductivity, flame-retardant and fire-resistant silicone rubber composite material.

[0051] The invention adopts the radiation vulcanization preparation process. Compared with the t...

Embodiment 1

[0066] (1) The mass fraction of each component raw material is: 80 parts of methyl vinyl silicone rubber, 20 parts of methyl vinyl phenyl silicone rubber, SiO 2 Airgel powder 15 parts, Fe 2 o 3 5 parts, ZrO 2 20 parts, 4 parts of low melting point glass powder, 4 parts of ZnO, 3 parts of TAIC, 30 parts of fumed silica, 3 parts of hydroxyl silicone oil, 20 parts of organic-inorganic compound flame retardant, 1 part of antioxidant 1010.

[0067] (2) The organic-inorganic compound flame retardant is formulated according to the mass fraction: the mass ratio of modified ATH, MCA, ZB and modified PEPA is 4:1:2:3.

[0068] (3) Each component is weighed in proportion, methyl vinyl silicone rubber, methyl vinyl phenyl silicone rubber, SiO 2 Add airgel powder, metal oxide powder, flux, hydroxy silicone oil, organic-inorganic compound flame retardant, and antioxidant 1010 into the internal mixer in sequence, and banbury at 70°C for 5 minutes, then add fumed white carbon black, The cr...

Embodiment 2

[0072] (1) The mass fraction of each component raw material is: 80 parts of methyl vinyl silicone rubber, 20 parts of methyl vinyl phenyl silicone rubber, SiO 2 Airgel powder 20 parts, Fe 2 o 3 5 parts, ZrO 220 parts, 4 parts of low melting point glass powder, 4 parts of ZnO, 3 parts of TAIC, 30 parts of fumed silica, 3 parts of hydroxyl silicone oil, 20 parts of organic-inorganic compound flame retardant, 1 part of antioxidant 1010.

[0073] (2) The organic-inorganic compound flame retardant is formulated according to the mass fraction: the mass ratio of modified ATH, MCA, ZB and modified PEPA is 4:1:2:3.

[0074] (3) Each component is weighed in proportion, methyl vinyl silicone rubber, methyl vinyl phenyl silicone rubber, SiO 2 Add airgel powder, metal oxide powder, flux, hydroxy silicone oil, organic-inorganic compound flame retardant, and antioxidant 1010 into the internal mixer in sequence, banbury at 70°C for 5 minutes, and then add fumed white carbon black , Cross-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com