Halogen-free antiflaming polylactic acid material and produciotn method of same

The technology of a polylactic acid material and a manufacturing method is applied in the field of halogen-free flame retardant polylactic acid material and its manufacturing, which can solve problems such as poor dispersion of flame retardants, and achieve the effects of small mechanical properties, reduced addition amount, and good toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

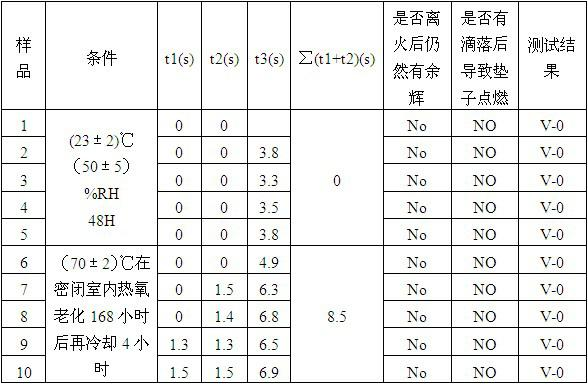

Examples

Embodiment 1

[0025] Example 1: 60 parts of high molecular weight polylactic acid with a viscosity average molecular weight of 100,000 or more, preferably 120,000, a melt index of 2-5g / 10min, preferably 40 parts of high melt strength polylactic acid of 5g / 10min, stearic acid 0.2 parts of sodium (dispersion aid) and 20 parts of polybutylene succinate (degradable toughening resin) were placed on a high-speed mixer and stirred evenly to obtain a mixed base material for later use. Put 42 parts of ammonium polyphosphate (abbreviated as APP), 28 parts of pentaerythritol, 20 parts of polybutylene succinate (polyester powder), and 10 parts of zinc borate (flame retardant synergist) in Stir evenly in a high-speed mixer to obtain a halogen-free flame retardant. The obtained mixed base material and halogen-free flame retardant were mixed in a high-speed mixer according to 6:4 (mass ratio), and then placed in a twin-screw extruder. The temperature of each section was set as: feeding port room temperatu...

Embodiment 2

[0026] Example 2: 60 parts of high molecular weight polylactic acid with a viscosity average molecular weight of 120,000, 40 parts of high melt strength polylactic acid with a melt index of 5 g / 10min, 0.2 parts of calcium stearate (dispersion aid), polybutylene 20 parts of butanediol diacid (degradable toughening resin) were placed on a high-speed mixer and stirred evenly to obtain a mixed base material for later use. Put 42 parts of ammonium polyphosphate (abbreviated as APP), 28 parts of pentaerythritol, 20 parts of polyhydroxyalkanoate (powder polyester), and 10 parts of zinc borate (flame retardant synergist) in a high-speed mixer Stir evenly in medium to obtain a halogen-free flame retardant. The obtained mixed base material and halogen-free flame retardant were mixed in a high-speed mixer at a ratio of 7:3 (mass ratio), and then placed in a twin-screw extruder. The temperature of each section was set as: room temperature at the feeding port- 50°C, feeding section 160-16...

Embodiment 3

[0027] Embodiment 3: The difference from Embodiment 1 is that the obtained mixed base material is mixed with the halogen-free flame retardant at a ratio of 8.5:1.5 (mass ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com