A polarity-modified polypropylene composite material and a preparing method thereof

A technology for composite materials and polypropylene, which is applied in the field of polar modified polypropylene composite materials and its preparation, can solve the problems of high cost of addition, damage to the mechanical properties of polypropylene systems, and expensive polymer polar additives. Achieve the effects of improving polarity, easy implementation and operation, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

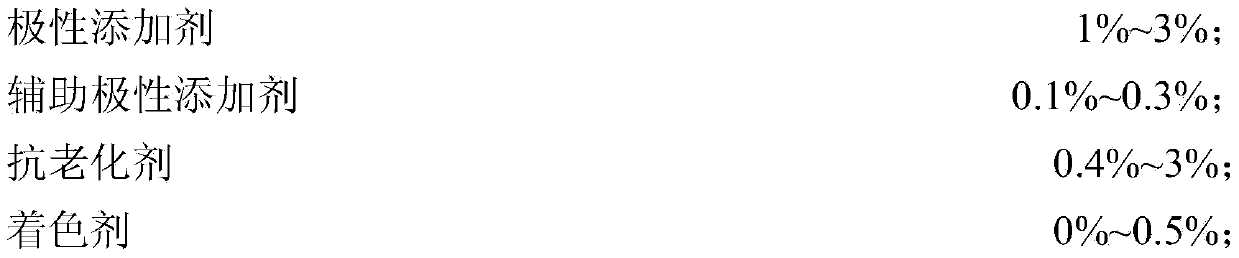

Method used

Image

Examples

Embodiment 1

[0041] 72 parts by weight of polypropylene, 10 parts by weight of POE (8150), 14 parts by weight of talcum powder, 3 parts by weight of EVA, 0.2 parts by weight of glycerol monostearate, 0.4 parts by weight of antioxidant 1010, 0.2 parts by weight of antioxidant 168. Add 0.2 parts by weight of carbon black into a high-speed mixer with a rotation speed of about 1000rpm and mix for 5 minutes, then put the mixture into a twin-screw extruder, extrude and granulate at a temperature of 190°C to 220°C, and obtain extremely Modified polypropylene composites.

[0042] The prepared polar-modified polypropylene composite was injection-molded into a bumper, and the firmness of the paint was verified by the cross-scratch method after spraying. By comparison, it was found that the bumper injection-molded from the material provided in Example 1 had good paint adhesion, and the paint did not fall off after being scratched and pulled three times with 3M adhesive tape. And the bumper that is i...

Embodiment 2

[0044] 72 parts by weight of polypropylene, 10 parts by weight of POE (8150), 14 parts of talcum powder, 3 parts by weight of EAA, 0.2 parts by weight of glycerol monostearate, 0.4 parts by weight of antioxidant 1010, 0.2 parts by weight of anti-oxidant Add oxygen agent 168 and 0.2 parts by weight of carbon black into a high-speed mixer with a rotation speed of about 1000rpm and mix for 5 minutes, then put the mixture into a twin-screw extruder, and extrude and granulate at a temperature of 190°C to 220°C. A polar-modified polypropylene composite material is obtained.

[0045] The prepared polar-modified polypropylene composite was injection-molded into a bumper, and the firmness of the paint was verified by the cross-scratch method after spraying. The paint firmness of the modified polypropylene bumper parts was also verified by the cross scraping method, and it was found that the bumper injection molded from the material provided in Example 2 had good paint adhesion and did ...

Embodiment 3

[0047] With 72 parts by weight of polypropylene 72 parts, 10 parts by weight of POE (8150), 15.5 parts of talcum powder, 1.5 parts by weight of EAA, 1.5 parts by weight of EVA, 0.2 parts by weight of glycerol monostearate, 0.4 parts by weight of antioxidant 1010 , 0.2 parts by weight of antioxidant 168, 0.2 parts by weight of carbon black were added to a high-speed mixer with a rotation speed of about 1000rpm and mixed for 5 minutes, and then the mixture was put into a twin-screw extruder and extruded at a temperature of 190°C to 220°C Obtained by granulation to obtain a polar modified polypropylene composite material.

[0048] The prepared polar-modified polypropylene composite was injection-molded into a bumper, and the firmness of the paint was verified by the cross-scratch method after spraying. The paint firmness of the modified polypropylene bumper was also verified by the cross scraping method, and it was found that the bumper injection-molded from the material provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com