Slurry for secondary batteries

A secondary battery and slurry technology, applied in battery electrodes, lithium storage batteries, battery pack components, etc., can solve problems such as short-circuit expansion, battery short-circuit, and reaction heat generation, and achieve excellent reliability, excellent cycle characteristics, The effect of excellent heat shrinkage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] (Method for preparing organic particles)

[0082] The method for producing the organic particles is not particularly limited, and the following methods are exemplified: dissolving or dispersing the above-mentioned monomers constituting the organic particles and other optional components as needed in a dispersion medium, and using emulsion polymerization, soap-free emulsion polymerization, or dispersion. Polymerization method Polymerization is carried out in the above-mentioned dispersion liquid.

[0083] In emulsion polymerization, it is preferable to divide and carry out polymerization in several stages in order to obtain desired particle diameter and average circularity. For example, first, a part of the monomer constituting the organic particle is polymerized to form a seed polymer particle, and then the seed polymer particle is allowed to absorb other monomers and polymerized in this state to prepare an organic particle (seed polymerization method). In addition, wh...

Embodiment 1

[0353]

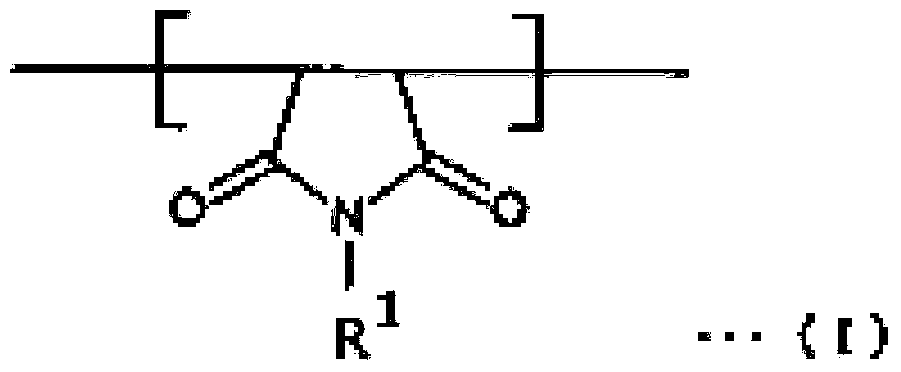

[0354] Put 100 parts of isobutylene-maleic anhydride copolymer (Kuraray Co., Ltd., trade name: ISOBAM (registered trademark)-04) into a reactor equipped with a stirrer, blow ammonia gas into it, and cool it in a water bath. At the same time, react until The exotherm ceased (about 1 hour). Next, ammonia gas was pressurized while heating in an oil bath, and the temperature was raised to 200° C. while distilling generated water out of the system to perform an imidization reaction. After completion of the reaction, the reaction product was taken out, heated and dried to obtain a maleimide-maleic anhydride copolymer A. The composition of the obtained maleimide-maleic anhydride copolymer A was 50 mol % of isobutylene structural units, 30 mol % of maleic anhydride structural units, and 20 mol % of maleimide structural units.

[0355] 100 parts of the obtained maleimide-maleic anhydride copolymer A, 21.9 parts of sodium hydroxide, and 487.7 parts of ion-exchanged water wer...

Embodiment 2

[0380] Using the following water-soluble polymer B instead of the water-soluble polymer A obtained in the step (1-1) of Example 1, except that, a slurry for a secondary battery was produced in the same manner as in Example 1 to obtain a slurry with Porous membranes, organic separators and secondary batteries are evaluated. The results are shown in Table 1.

[0381]

[0382] Using the maleimide-maleic anhydride copolymer A produced in the step (1-1) of Example 1, put 100 parts of maleimide-maleic anhydride copolymer A in a reactor equipped with a stirrer, 21.9 parts of lithium hydroxide and 487.7 parts of ion-exchanged water were stirred at 90° C. for 5 hours to obtain an aqueous solution of water-soluble polymer B having a solid content concentration of 20%. In addition, the weight average molecular weight of the water-soluble polymer B was 60000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com