Thermal crosslinking type slurry for lithium ion battery, electrode, separator, separator/electrode laminate, and lithium ion battery

A lithium-ion battery, thermal cross-linking technology, applied in the direction of battery electrodes, electrode collector coatings, separators/films/diaphragms/spacers, etc. Changing the cycle characteristics of lithium-ion batteries is easy to reduce, etc., to achieve the effect of improving output characteristics and improving resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0248] Hereinafter, the present invention will be described more specifically with reference to Examples and Comparative Examples. The present invention is not limited by the following examples. In addition, unless otherwise specified, "parts" and "%" hereinafter represent parts by mass and % by mass, respectively.

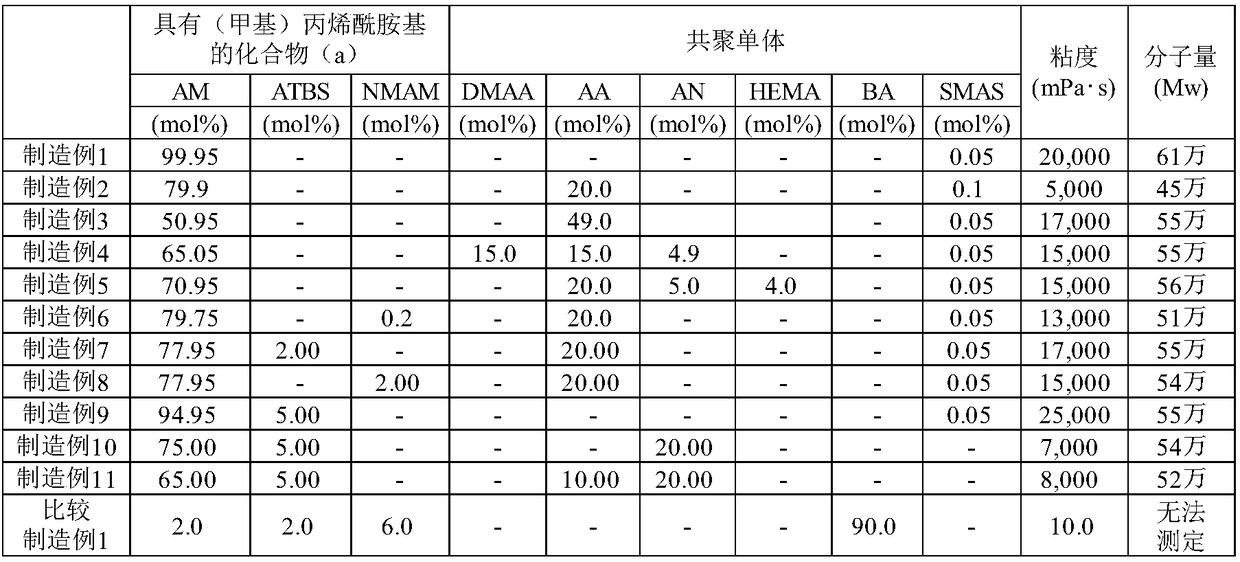

[0249] 1. Manufacture of component (A)

manufacture example 1

[0251] In a reaction apparatus equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen gas introduction tube, 1095 g of ion-exchanged water, 400 g (2.81 mol) of a 50% aqueous solution of acrylamide, and sodium methallylsulfonate were added. 0.22 g (0.0014 mol), after removing the oxygen in the reaction system by nitrogen, the temperature was raised to 50°C. Here, 2.0 g of 2,2′-azobis(2-amidinopropane) dihydrochloride (manufactured by Nippon Chemical Co., Ltd., trade name “NC-32”) and 50 g of ion-exchanged water were put in, and the temperature was raised to 80 The reaction was carried out at °C for 3 hours to obtain an aqueous solution containing polyacrylamide.

manufacture example 2

[0253] In a reaction apparatus equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen introduction tube, 1428 g of ion-exchanged water, 400 g (2.81 mol) of 50% aqueous acrylamide solution, 63.5 g (0.70 mol) of 80% aqueous acrylic acid solution, and methallyl were added. Sodium sulfonate 0.56g (0.0035mol). After the oxygen in the reaction system was removed by passing nitrogen, the temperature was raised to 50°C. Here, 2.5 g of 2,2′-azobis(2-amidinopropane) dihydrochloride (manufactured by Nippon Chemical Co., Ltd., trade name “NC-32”) and 50 g of ion-exchanged water were put in, and the temperature was raised to 80 The reaction was performed at °C for 3.0 hours to obtain an aqueous solution containing a polyacrylamide-acrylic acid copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com