Lithium ion battery diaphragm with hydrophilic cross-linking surface layer and manufacture method of lithium ion battery diaphragm

A lithium-ion battery, cross-linked layer technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problem of affecting battery cycle performance and charge-discharge efficiency, increase lithium-ion battery internal resistance, low porosity and air permeability and other problems, to achieve the effect of easy implementation, improved liquid absorption rate and liquid retention rate, high porosity and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

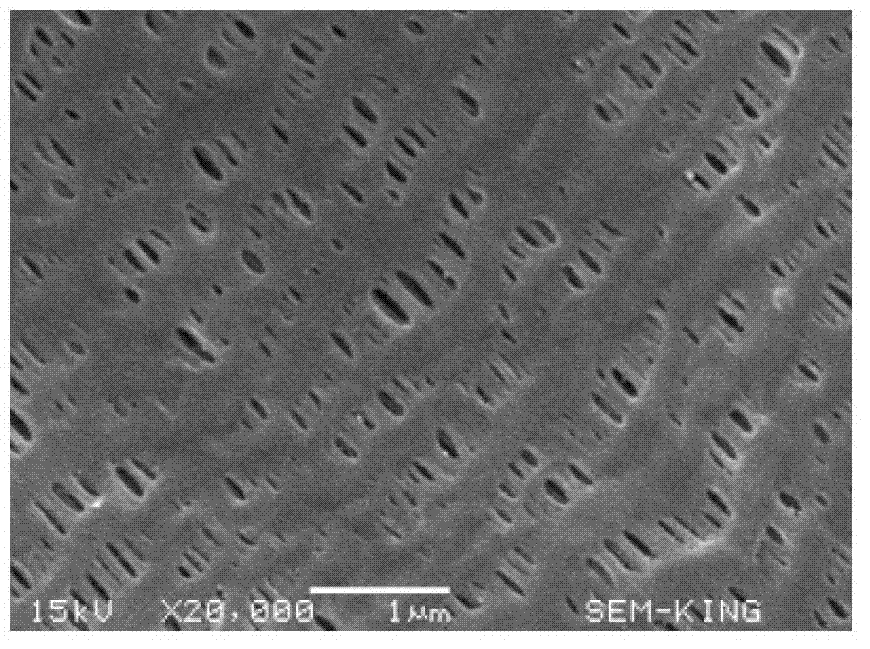

[0046] Add polyvinyl alcohol (polymerization degree 600, alcoholysis degree 78%) and distilled water into a three-necked flask at a ratio of 25:75 (wt%), heat up to 60°C in a water bath while stirring, stir and dissolve for 1 hour, and obtain polyvinyl alcohol Aqueous solution of vinyl alcohol. Soak the polypropylene microporous membrane in the solution for 30 minutes, and then take it out. Wash the polypropylene microporous membrane with dimethyl sulfoxide, and then dry the microporous membrane with hot air at 80° C. for 10 minutes to obtain a polypropylene microporous membrane whose pores are filled and protected by polyvinyl alcohol.

[0047] Submerge the polypropylene microporous membrane filled and protected by polyvinyl alcohol into an ethanol solution containing 1% benzoin dimethyl ether and 20% N-hydroxyethylacrylamide, blow in nitrogen to remove the air, and irradiate with ultraviolet light for 10 minutes. After the membrane is taken out, the surface of the membrane ...

Embodiment 2

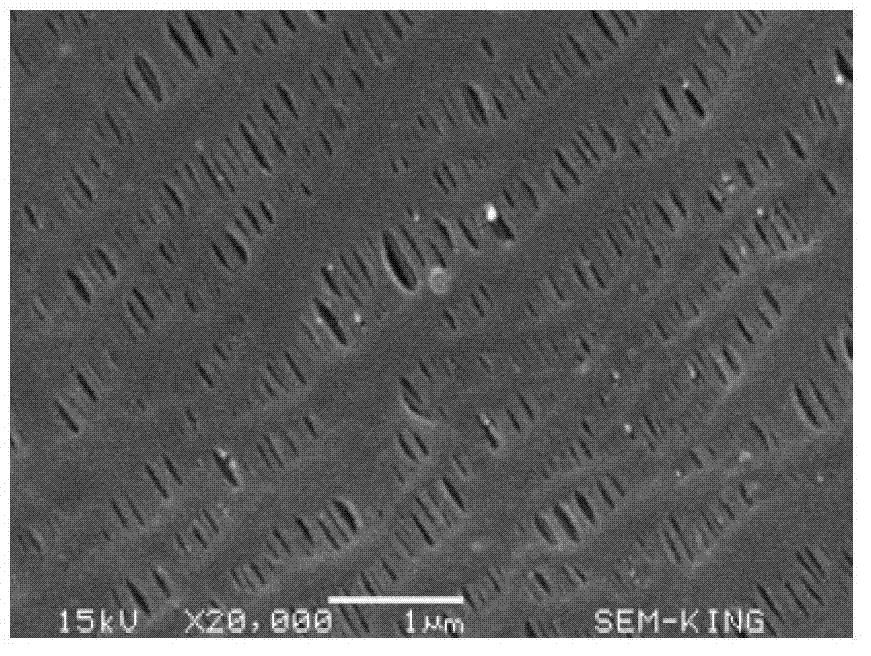

[0051] The chemical grafting of the polypropylene microporous membrane in Example 1 was changed from UV-induced grafting to initiator-induced grafting. The steps for the initiator to initiate grafting are: immerse the polypropylene microporous membrane filled and protected by polyvinyl alcohol into an ethanol solution containing 0.3% potassium persulfate and 5% N-hydroxyethylacrylamide, and react at 70°C After 3 hours, the membrane surface was washed with acetone after the membrane was taken out to obtain a polypropylene microporous membrane grafted with N-hydroxyethylacrylamide on the surface.

[0052] All other steps were the same as in Example 1 to obtain a polypropylene microporous membrane with a hydrophilic cross-linked layer on the surface. The performance data of the modified microporous membrane are listed in Table 1.

Embodiment 3

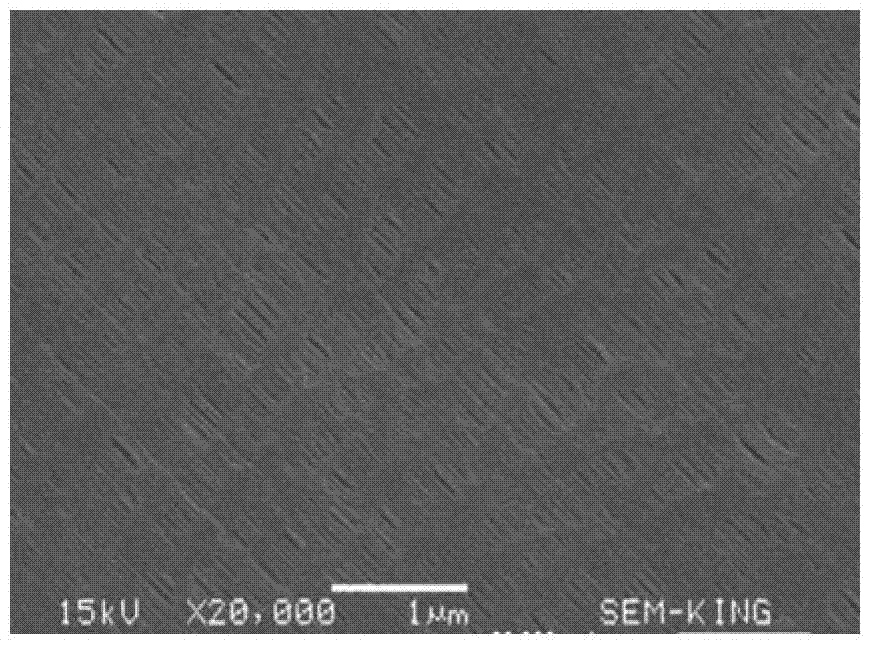

[0054] Polyvinyl alcohol (polymerization degree 2000, alcoholysis degree 78%) and distilled water were prepared into a polyvinyl alcohol aqueous solution at a ratio of 25:75 (wt%), and the rest were the same as in Example 1. The performance data of the modified microporous membrane As described in Table 1.

[0055] Due to the high degree of polymerization of polyvinyl alcohol and the high viscosity of its aqueous solution, it is difficult for the polymer solution to fill the pores of the microporous membrane. Therefore, the protection of polyvinyl alcohol on the pores of the microporous membrane is insufficient, resulting in a large decrease in the porosity and air permeability of the modified PP microporous membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com