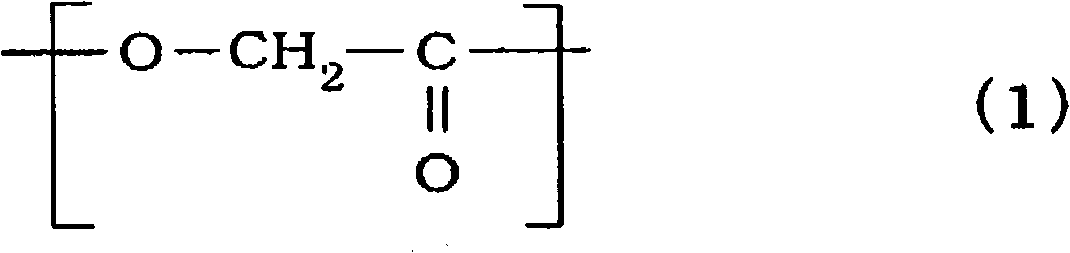

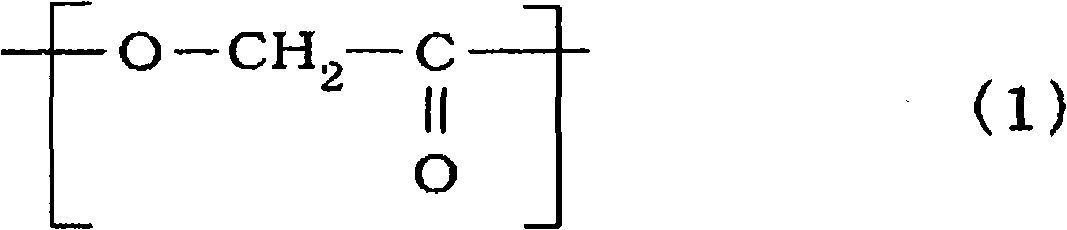

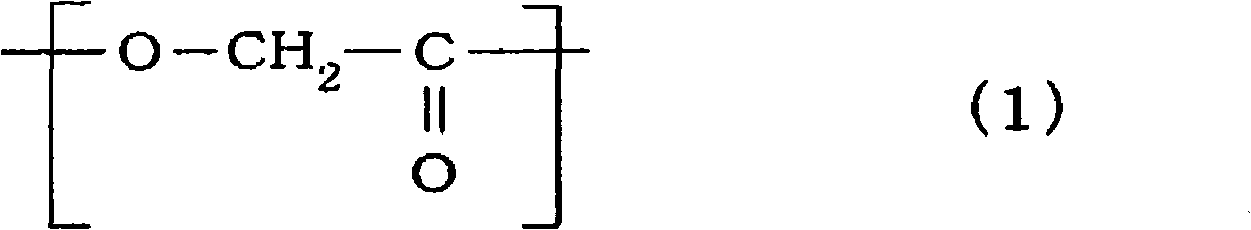

Successively biaxially stretched polyglycolic acid film, process for producing the successively biaxially stretched polyglycolic acid film, and multilayered film

A polyglycolic acid film and polyglycolic acid technology, applied in chemical instruments and methods, coatings, flat products, etc., can solve the problems of industrial-scale manufacturing of successively biaxially stretched polyglycolic acid films, transparency, and heat-resistant shrinkage In order to solve the problems of difficult property resistance and easy shrinkage of uniaxially stretched film, it achieves the effects of excellent transparency, low oxygen transmission coefficient, high falling ball impact strength and puncture strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0193] A single-screw extruder with a screw diameter of 35mm is used to heat and melt the raw material particles of PGA-1, so that the resin temperature is 260-270°C. The melt was passed through a filter with an opening size of 100 μm, extruded from a T-die having a linear slit with a length of 270 mm and a gap of 0.75 mm, cooled by casting on a metal drum whose surface was kept at 40° C., Thus, an unstretched sheet having a thickness of 200 μm was produced.

[0194] The unstretched sheet adjusted to a sheet temperature of 60° C. was uniaxially stretched in the machine direction (MD) at a stretching speed of 2 m / min using stretching rolls so that the stretching ratio was 6.0 times (step 1).

[0195] Then, cooling was performed for about 15 seconds with a radiator and a cooling roll so that the surface temperature of the uniaxially stretched film was 33° C. (step 2).

[0196] Next, the uniaxially stretched film is introduced into the expander, stretched in the transverse direc...

Embodiment 2

[0200] A sequential biaxially stretched film was produced in the same manner as in Example 1 except that the operating conditions of steps 1 to 4 were changed to those shown in Table 1. The operating conditions and results are shown in Tables 1 and 2.

Embodiment 3

[0202] A sequential biaxially stretched film was produced in the same manner as in Example 1 except that the operating conditions of steps 1 to 4 were changed to those shown in Table 1. The operating conditions and results are shown in Tables 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com