Polyolefin microporous film and its manufacture method, and spacer for battery and battery

A technology of microporous film and manufacturing method, which is applied in the direction of battery pack parts, lithium storage batteries, electrical components, etc., can solve the problems of uncontrolled accelerated reaction, performance (insufficient heat shrinkage resistance, etc.), and achieve low cut-off temperature and safety and excellent productivity, excellent permeability and mechanical properties

Active Publication Date: 2008-11-26

TORAY IND INC

View PDF7 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the case of causing a runaway reaction of the battery, if the separator shrinks in the temperature range from the start of the shutdown to the end of the shutdown, a short circuit occurs at its end, and as a result, the runaway reaction is accelerated.

However, the microporous membranes described in each of the above-mentioned documents are insufficient in the ability to maintain the shape and prevent short circuits (heat shrinkage resistance) in the temperature range from the shutdown start temperature to the shutdown temperature.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

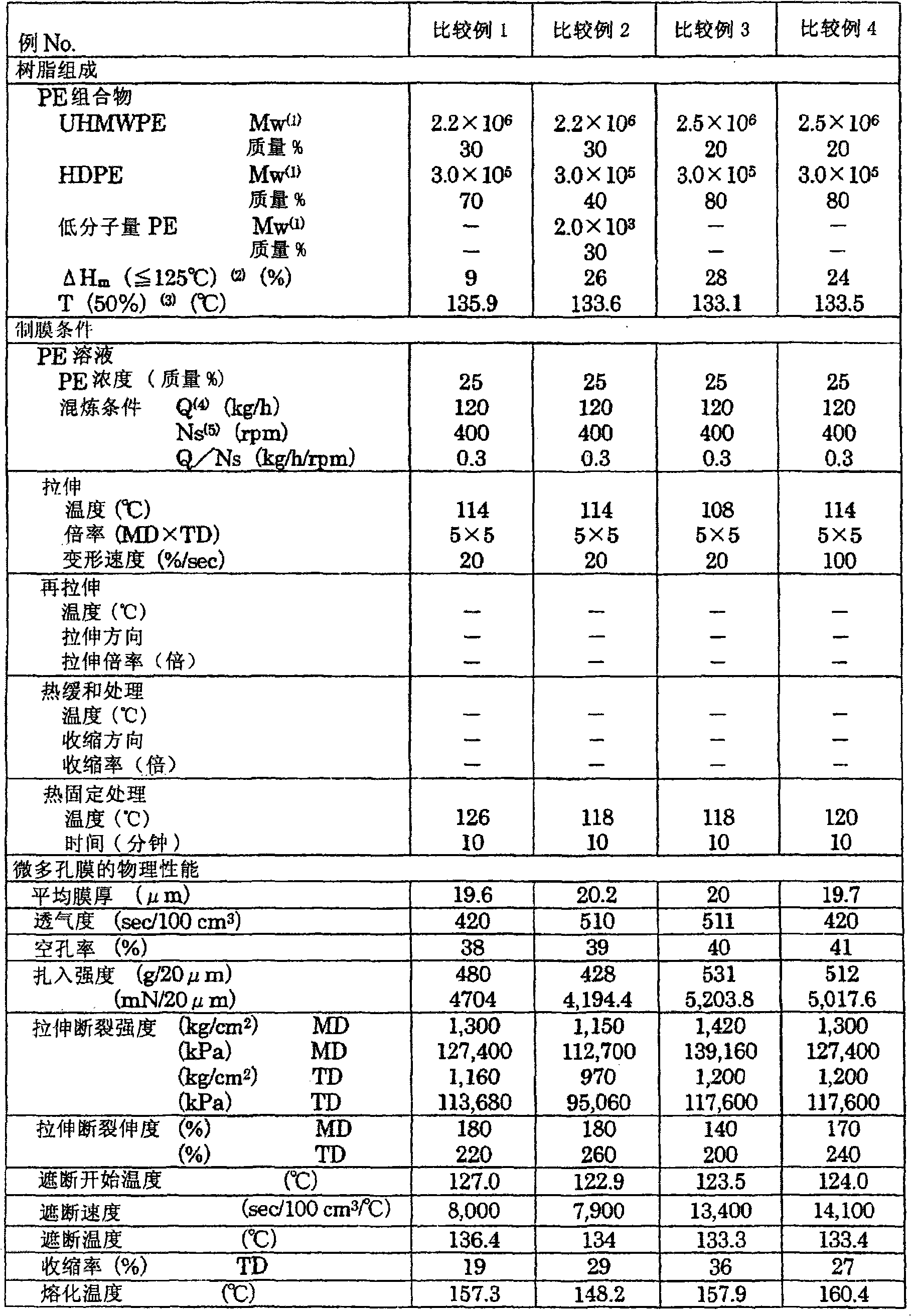

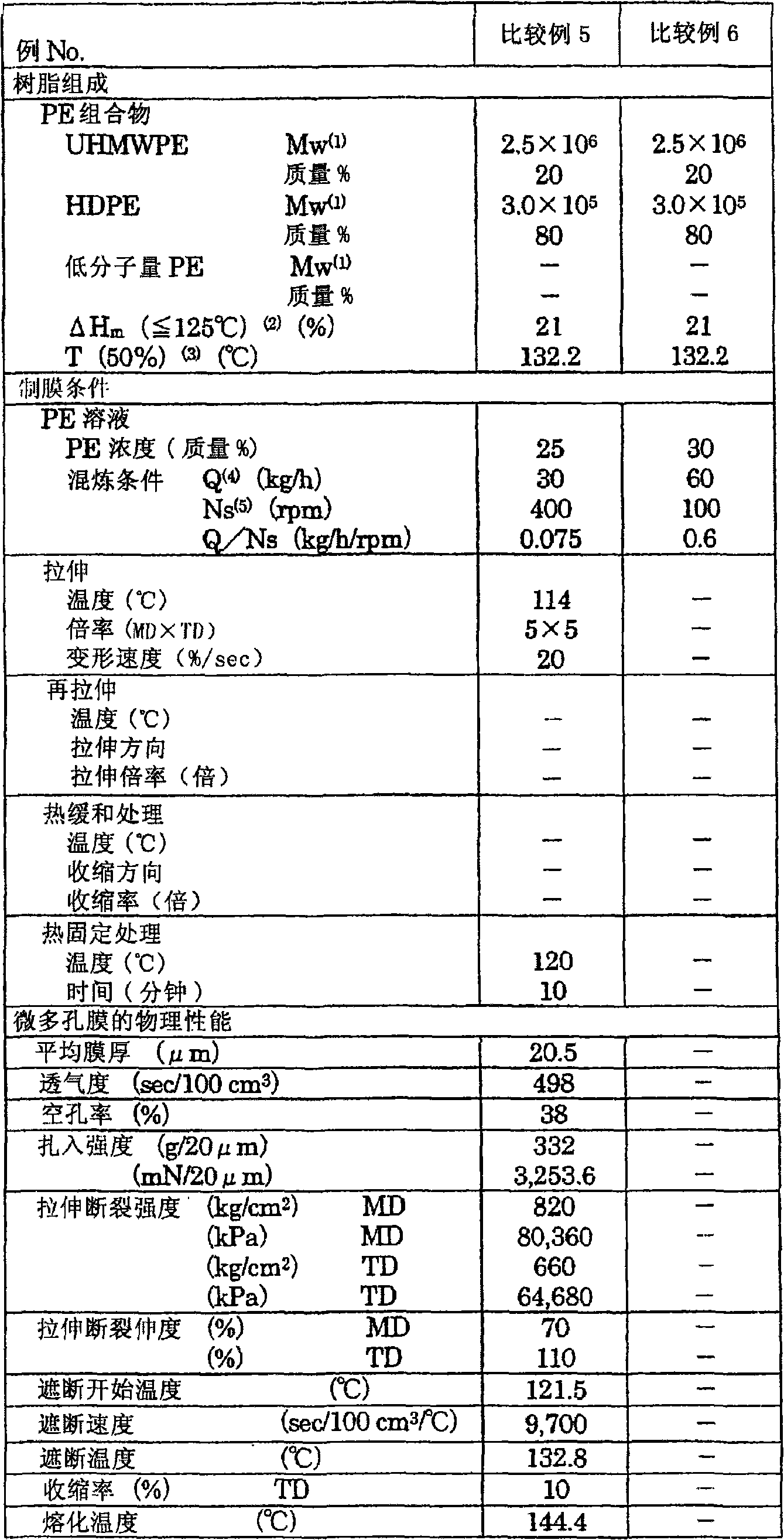

Experimental program

Comparison scheme

Effect test

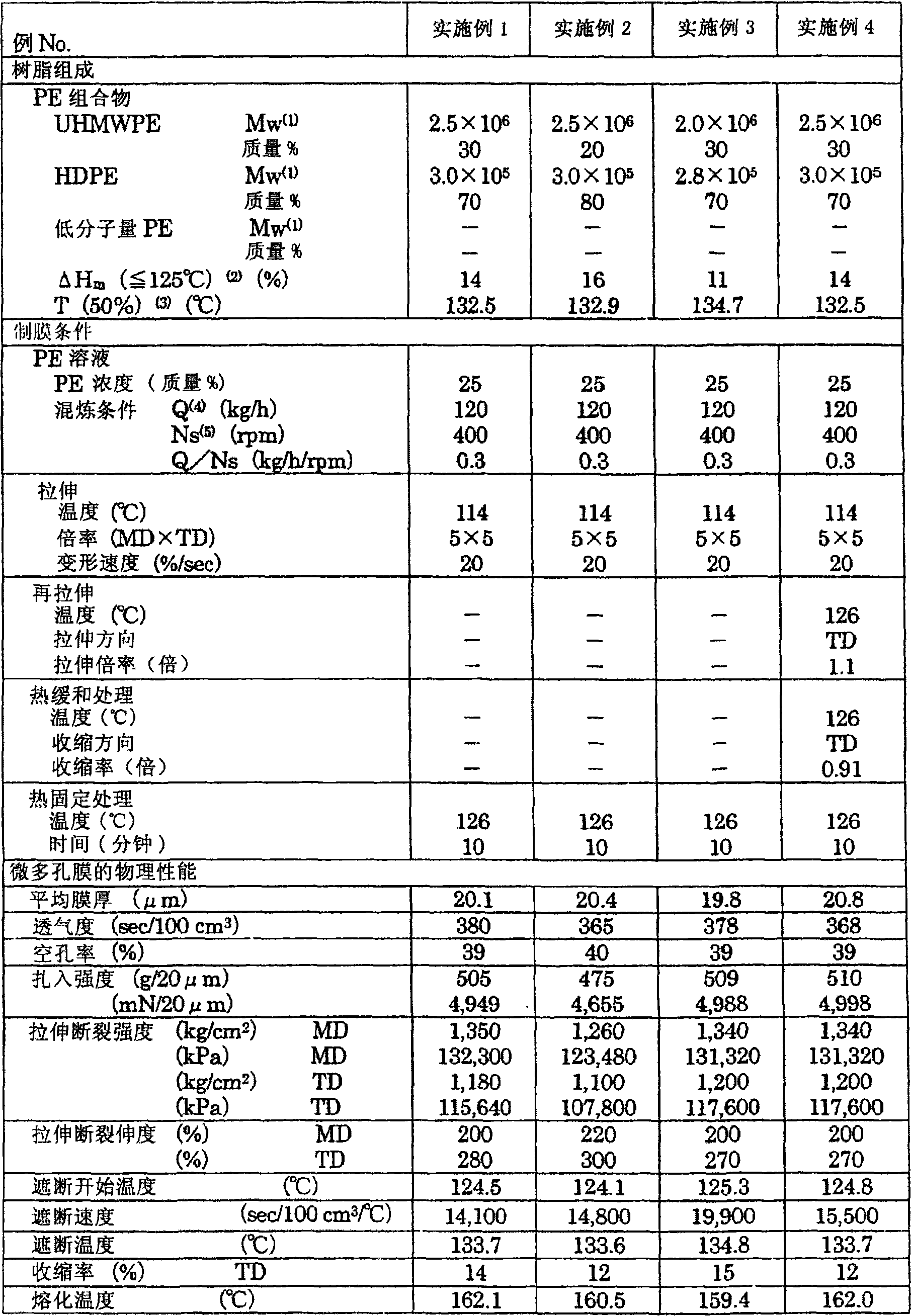

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

A polyolefin porous membrane is characterized by comprising a polyethylene resin, and is further characterized in that (a) the shutdown temperature is 135 DEG C or lower which is the temperature at which the gas permeability as measured with heating at a heating rate of 5 DEG C / min reaches 1*10<5> sec / 100 cm<3>, (b) the change rate of the gas permeability is 1*10<4> sec / 100 cm<3> or more, the change rate of the gas permeability is the gradient at the coordinate on the curve representing the dependency of the gas permeability to the temperature when the gas permeability is 1*10<4> sec / 100 cm<3>, (c) the transverse shrinkage factor measured at 130 DEG C through the analysis of heating mechanism at a load of 2gf and a heating rate of 5 DEG C / min is 20% or below.

Description

Polyolefin microporous film, method for producing same, separator for battery, and battery technical field The present invention relates to a polyolefin microporous film, a method for producing the same, a separator for a battery, and a battery, and particularly relates to the stability of physical properties up to the start of shutdown, the high rate of change in air permeability after the start of shutdown, and the stability from the shutdown start temperature to the shutdown temperature. A polyolefin microporous film excellent in heat shrinkage resistance in a temperature range and having a low shutdown temperature, a method for producing the same, a separator for a battery, and a battery. Background technique Polyethylene microporous membranes are mainly used as separators for batteries. Especially for separators for lithium-ion batteries, not only excellent mechanical properties and permeability are required, but also the following properties are required: the battery ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08J9/00C08J9/26H01M2/16H01M10/40H01M10/052H01M10/36H01M50/417H01M50/491H01M50/494

CPCH01M10/24H01M2/1653H01M10/4235H01M10/052Y10T428/249921Y02E60/10H01M50/417H01M50/491H01M50/494C08J9/22C08J9/26C08J5/22H01M10/05

Inventor 君岛康太郎开米教充

Owner TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com