Microporous member, method for producing same, battery separator, and resin composition for nonaqueous electrolyte secondary battery separator

A technology of resin composition and microporous membrane, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problem of insufficient thermal shrinkage resistance of microporous membranes, and achieve the effect of excellent thermal shrinkage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

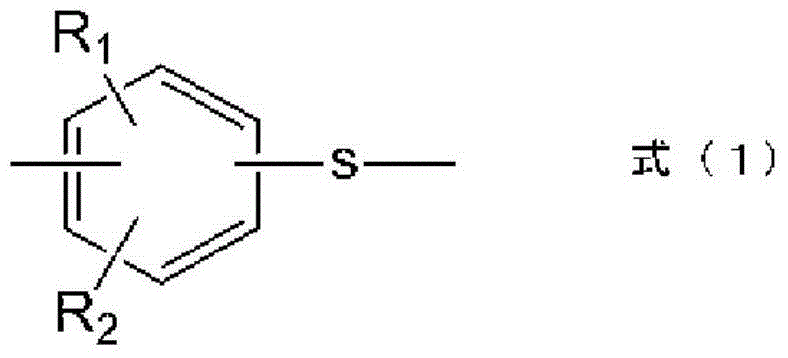

Method used

Image

Examples

Embodiment 1~8、 comparative example 1~3

[0172] The polyphenylene sulfide resin, polyolefin resin-1, and thermoplastic elastomer shown in Tables 1 to 3 below were uniformly mixed in a tumbler to form a compounded material. After that, the above-mentioned compounded materials were put into a twin-screw extruder with a vent port (manufactured by Japan Steel Works "TEX-30"), and melted and kneaded (resin component discharge rate 20kg / hr, screw speed 350rpm, the ratio of the discharge rate of the resin component is 0.057 (kg / hr / rpm), the maximum torque is 60 (A), the set resin temperature refers to the following table 1-3 "Process 1: Cylinder temperature", the mold hole diameter is 3mm ), and then, the aperture of the mold (nozzle diameter) and the diameter of the strand (that is, the diameter of the strand) are collected in the form of Table 1-3 "Mold Aperture / Strand Diameter", and the strand is prepared at the same time, cut off, and the resin is obtained Granules of the composition. In addition, the strand diameter i...

Embodiment 9~16、 comparative example 4~6

[0190] The polyphenylene sulfide resin, polyolefin resin-1, and thermoplastic elastomer shown in Tables 4 to 6 below were uniformly mixed in a tumbler to form a compounded material. After that, the above-mentioned compounded materials were put into a twin-screw extruder with a vent port (manufactured by Japan Steel Works "TEX-30"), and melted and kneaded (resin component discharge rate 20kg / hr, screw speed 350rpm, the ratio of the discharge rate of the resin component is 0.057 (kg / hr / rpm), the maximum torque is 60 (A), the set resin temperature refers to the following table 4-6 "Process 1: Cylinder temperature", the mold hole diameter is 3mm ), and then collected in the manner of Table 4-6 "die diameter / strand diameter", and prepared strands at the same time, cut to obtain pellets of the resin composition.

[0191] Next, the pellets of the resin composition obtained in the aforementioned process, the polyolefin resin-2 described in Tables 4 to 6, and the pore forming agent (li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com