Rubber powder modified emulsified asphalt and preparation method thereof and CA mortar prepared by emulsified asphalt

A technology of emulsified asphalt and rubber powder, used in modified emulsified asphalt, rubber powder modified emulsified asphalt, rubber powder modified emulsified asphalt used in the field of CA mortar for high-speed railway or light rail slab trackless track, can solve the problem of CA Mortar performance requirements, short storage time, easy bleeding and segregation of CA mortar, etc., to achieve excellent temperature adaptability and workability, high early strength, and eliminate adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 6

[0055] The preparation method of embodiment 1 to embodiment 6 modified emulsified asphalt is as follows:

[0056] (1) Assuming the measured coupling agent and 1 / 3 of the diluted dispersant in the rubber powder, stir at 120°C for 1 hour;

[0057] (2) Heat the asphalt to 160-230°C, add the remaining amount of diluting dispersant, then add the modified rubber powder prepared in (1), and stir at this temperature for 2-4 hours;

[0058] (3) Add hot water (75-85°C) to the measured emulsifier and emulsification aid, and stir fully to prepare an emulsifier solution;

[0059] (4) Add the emulsifier solution and the metered thickener quickly to the rubber powder modified asphalt prepared in (2), and use a high-shear mixer to shear at high speed for 60-180 seconds.

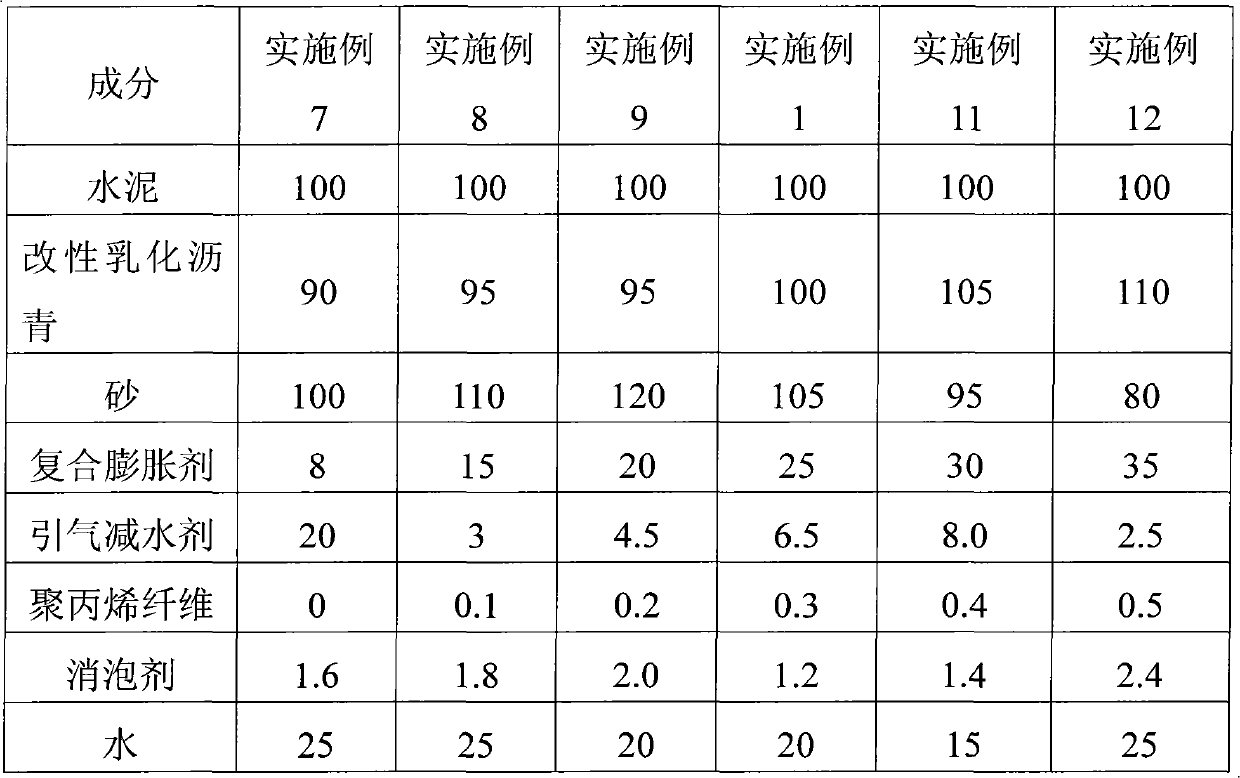

[0060] The rubber powder modified emulsified asphalt prepared in Examples 1 to 6 was used to prepare CA mortar, and in Examples 7 to 12. The mixing ratio of CA mortar in each example is shown in Table 2.

[0061] Table 2: ...

Embodiment 7 to Embodiment 12

[0063] The preparation method of CA mortar in embodiment 7 to embodiment 12 is as follows:

[0064] (1) Add rubber powder modified emulsified asphalt into the mixer, and stir at a low speed (30-40rpm);

[0065] (2) Add water and water reducer in sequence, and continue stirring at low speed (30-40rpm) for 5-25 seconds;

[0066] (3) Add cement, composite expansion agent, sand and polypropylene fiber, gradually increase the stirring speed to 200rpm-600rpm, and keep stirring for 30-90 seconds.

[0067] (4) Add defoamer and stir at low speed for 5-20 seconds to obtain CA mortar product.

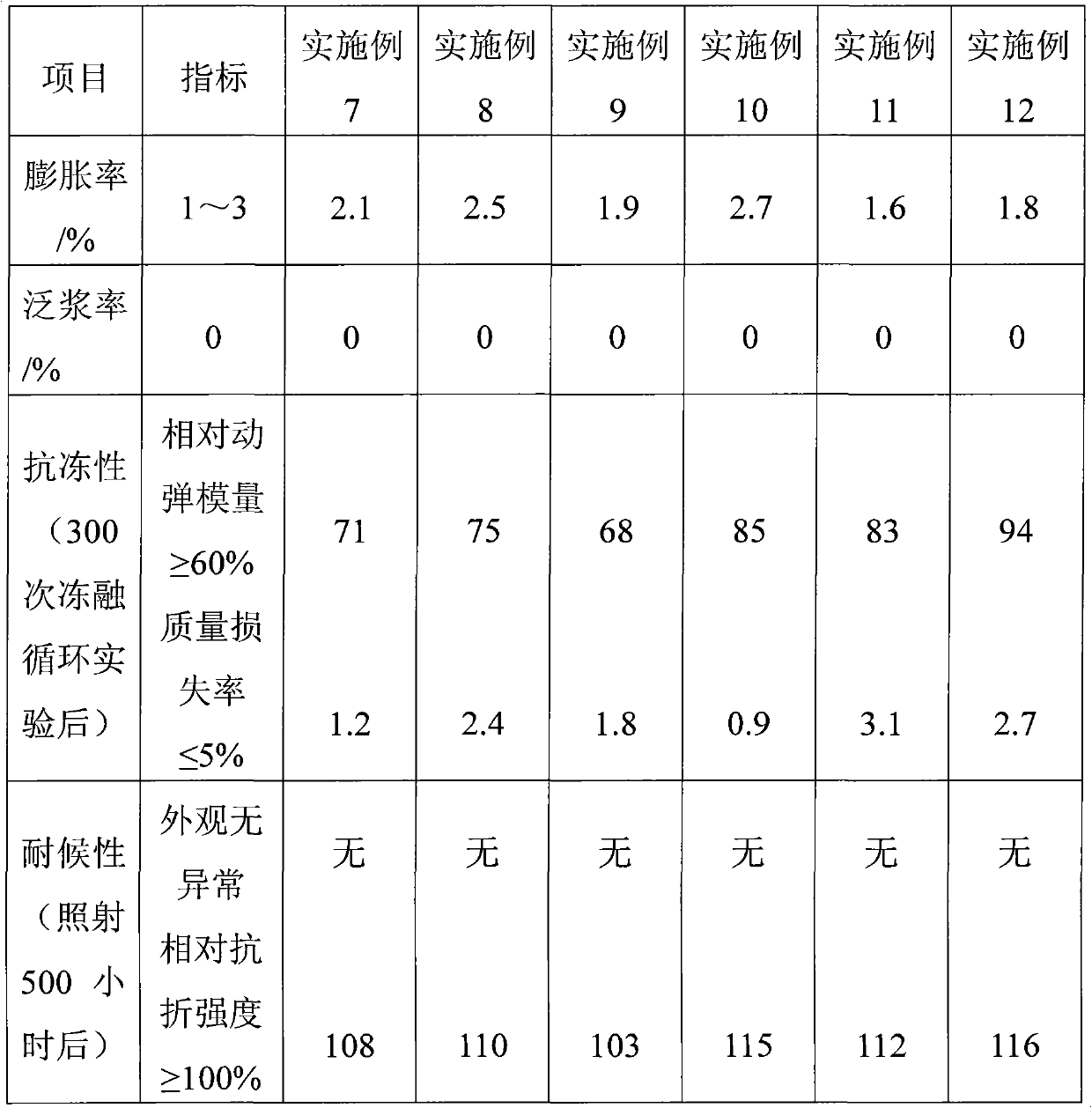

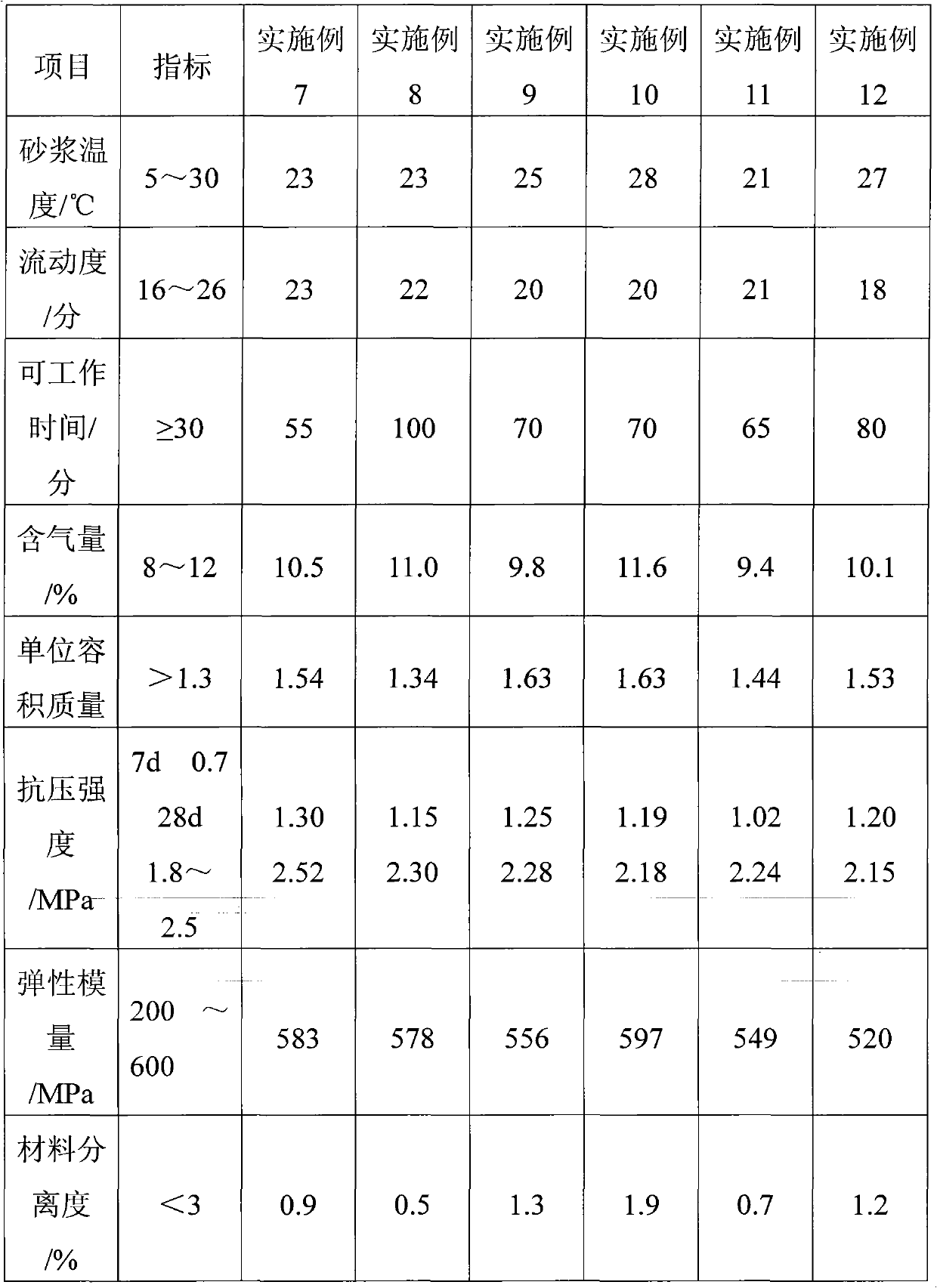

[0068] According to the test method stipulated in the "Code for Design of Railway Tracks" (TB10082-2005), the performance of the CA mortar was measured, and the performance indicators of the CA mortar in Examples 7 to 12 are shown in Table 3.

[0069] It can be seen from the above specific examples and various data tables that the present invention solves the compatibility between rubber powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com