Antifogging coating, special antifogging coating composition and antifogging product thereof

An anti-fog coating and composition technology, applied in the direction of coating and the like, can solve the problems such as the lack of widespread promotion of anti-fog functional coatings, insufficient anti-fog duration, and poor anti-fog surface hardness, and achieve excellent anti-fog properties, The effect of good surface smoothness and clarity, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

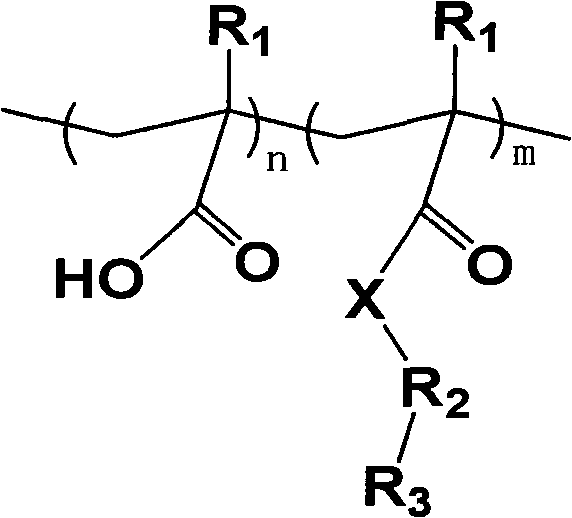

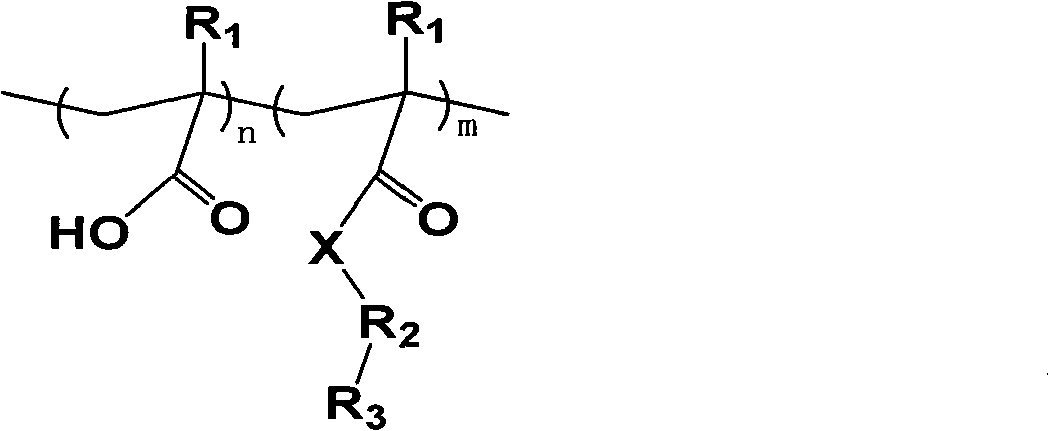

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, preparation has the PET product of anti-fog coating

[0045] With the aqueous solution of 100g 60% polyacrylic acid-polyacrylamide-2-methylpropanesulfonic acid (Shandong Taihe Water Treatment Co., Ltd.) (average molecular weight is 2000Da), 1.5g aziridine cross-linking agent CX100 (DSM company) , 10g particle diameter is the hydrosol (concentration is 50%) of the silica nanoparticle (Nissan Chemical Industries, Ltd.) of 20nm of 20nm and mixes, and adding a small amount of hydrochloric acid that is 1mol / L in the above-mentioned mixture, adjusts the pH value 2 to 4, and then add 0.3g silane coupling agent TEOS (tetraethyl orthosilicate) (Beijing Jingyi Chemical). The above mixture was coated on the surface of PET (polyethylene terephthalate) with a wire bar, and the PET was dried at 120° C. for 5 minutes to obtain a PET article with an anti-fog coating thickness of 1 μm.

[0046] Determination of physical properties:

[0047] Anti-fog performance: >1 minut...

Embodiment 2

[0053] Embodiment 2, preparation has the PC product of anti-fog coating

[0054] With the aqueous solution of 100g 40% polyacrylic acid-polyacrylamide-2-methylpropanesulfonic acid-polyacrylic acid (2-hydroxyethyl) ester (Shandong Taihe Water Treatment Co., Ltd.) (average molecular weight is 2000Da), 4g aziridine Crosslinking agent CX100, 200g particle diameter is the silica nanoparticle hydrosol (concentration is 30%) of 8nm and mixes, and adding a small amount of hydrochloric acid that concentration is 1mol / L in the above-mentioned mixture, adjusts the pH value to be 2 to 4, additionally Add 3g of silane coupling agent KH560 (glycidyl ether propyltrimethoxysilane) (Nanjing Nengde Chemical Co., Ltd.) and stir evenly. Use a wire rod to coat the above mixture on the surface of PC (polycarbonate), and place PC on Dry at 150° C. for 2 minutes to obtain a PC product with an anti-fog coating thickness of 5 μm.

[0055] Determination of physical properties:

[0056] Anti-fog perfor...

Embodiment 3

[0062] Embodiment 3, prepare the PMMA goods with anti-fog coating

[0063] With 100g 30% polyacrylic acid-propenyl alkyl ether sodium sulfonate (Aldrich imported reagent) (average molecular weight is 7000Da) aqueous solution, 0.3g aziridine crosslinking agent CX100, 100g particle diameter is the silica nanoparticle of 5nm Mix the hydrosol (concentration is 30%), add a small amount of hydrochloric acid with a concentration of 1mol / L to the above mixture, adjust the pH value from 2 to 4, and add 2.5g of silane coupling agent TEOS (tetraethyl orthosilicate) to stir Evenly, the above mixture is coated on the surface of PMMA with a wire rod, and the PMMA is dried at 100° C. for 15 minutes to obtain a PMMA product with an anti-fog coating thickness of 2 μm.

[0064] Determination of physical properties:

[0065] Anti-fog performance: >1 minute (50°C water vapor), qualified;

[0066] Surface hardness: H;

[0067] Abrasion resistance (750g, 500r) g: 0.03;

[0068] Cohesion: <95%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com