Trimethylbenzene separation method

A technology for mesitylene and mesitylene is applied in the field of separation of mesitylene, which can solve the problems of difficult industrial application, complicated process, low purity of mesitylene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

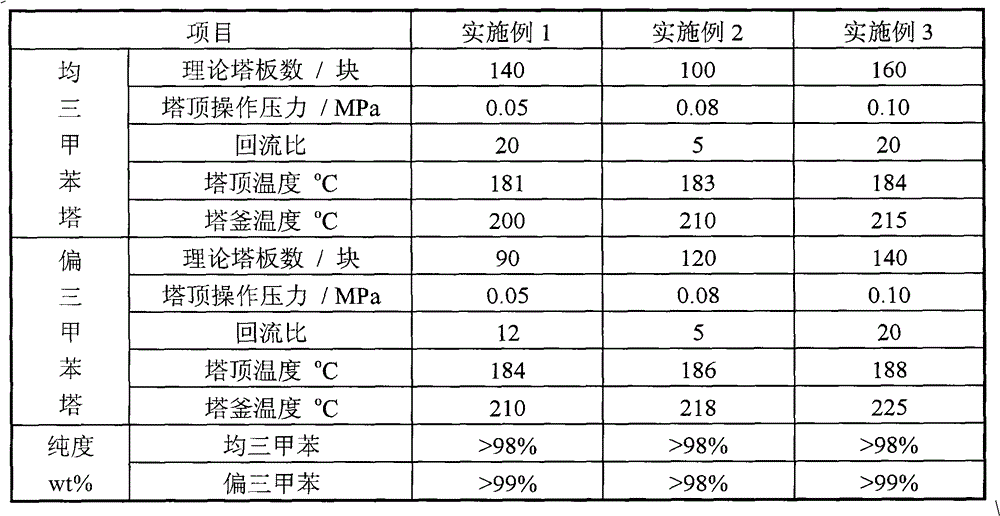

Embodiment 1~3

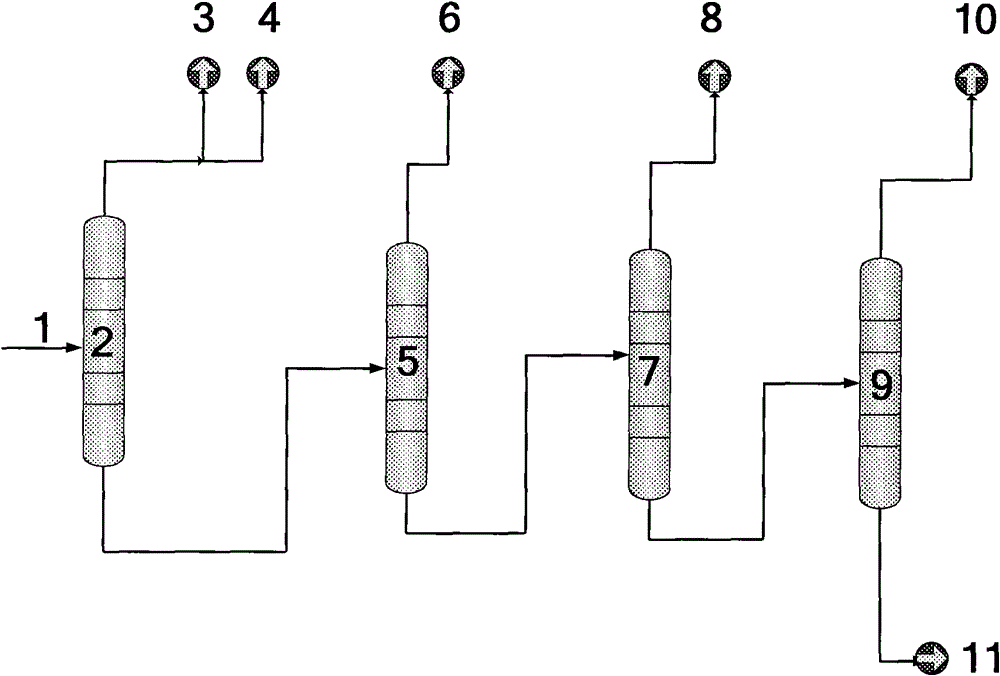

[0017] Binder-free ZSM-5 zeolite (SiO 2 / Al 2 o 3 The molar ratio is 60) It is prepared with reference to the Chinese patent CN1915820, and is converted into hydrogen-type zeolite by roasting after ion exchange with ammonium nitrate solution. The catalyst is obtained by impregnating 0.05% of Pt and 0.25% of Zn in the loading weight ratio on the hydrogen-type binderless ZSM-5 zeolite, and calcining at 450°C. After catalyst activation, adopt the raw material of table 1, be 400 at hydrogen oil volume ratio (v / v), reaction pressure is 2.8MPa, weight hourly space velocity is 2.1 hours -1 , under the condition that the reaction temperature is 370° C., the raw materials in Table 1 are subjected to hydrocracking treatment, and the composition of the obtained products is shown in Table 1. cracked products according to figure 1 The process first enters the stripping tower, the top of the stripping tower gets non-condensable tail gas and liquid light hydrocarbons, the bottom material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com