A method for preparing methyl styrene and co-producing mesitylene from C9 aromatic hydrocarbon mixture dehydrogenation and alkyl aromatic hydrocarbon dehydrogenation catalyst

A technology for methyl styrene and dehydrogenation catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of increased operating energy consumption, The problem of high energy consumption of fractional distillation achieves the effect of cost saving, energy consumption reduction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

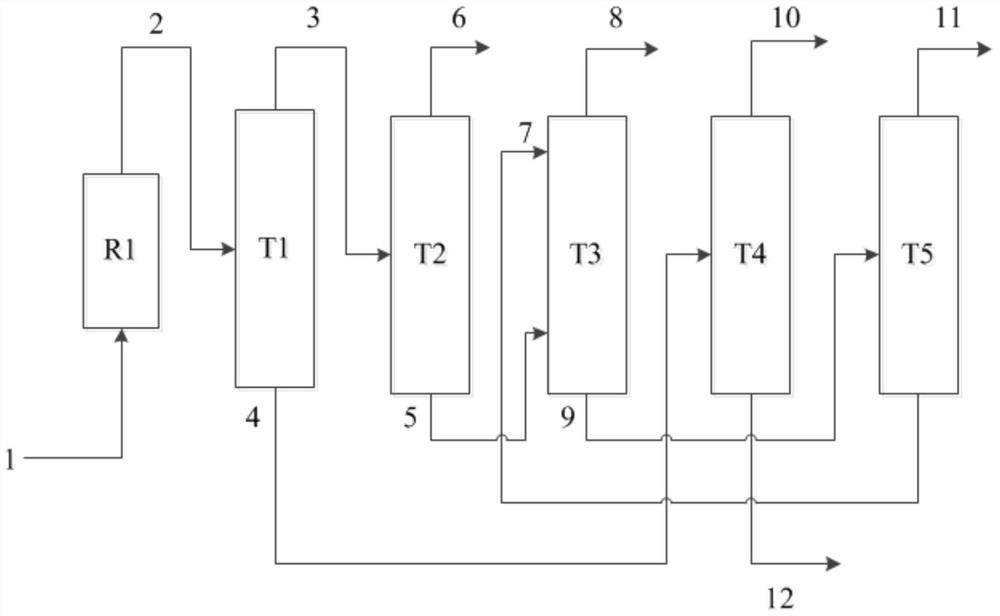

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a specific embodiment of the preparation method of the alkylaromatic dehydrogenation catalyst. The specific steps may include: weighing Fe, K (excluding K in the binder and pore-forming agent), Ce, Compounds of Ca, Zr, La and Sr, binders and pore-forming agents are mixed and pulverized in a pulverizer for 10 to 20 minutes, and an appropriate amount of deionized water is added and kneaded for 30 to 120 minutes by a kneader, and the prepared The viscous paste is extruded and diced to make Φ1×(1-3) mm particles, dried at 120°C for 6-12 hours, and then roasted at 400-900°C for 4-8 hours in an air atmosphere to obtain alkyl Aromatic dehydrogenation catalyst.

[0049] In the above specific embodiment, the pore-forming agent can be selected from polystyrene microspheres and hydroxyethyl cellulose, and its addition can be 5 to 15% by mass of the dry basis of the catalyst; ferric oxide can be Iron oxide red (Fe 2 O 3 ) and iron oxide yellow...

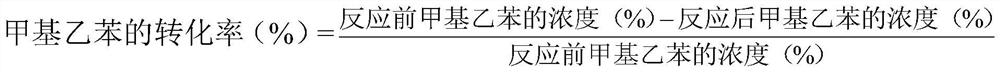

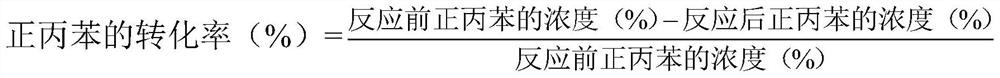

Embodiment 1

[0068] Weigh 40.7 grams of iron oxide red Fe 2 O 3 , 20.3 grams of iron oxide yellow Fe 2 O 3 ·H 2 O, 16.1 grams of potassium carbonate, 7 grams of CeO 2 , 5 grams of CaO, 7.8 grams of zirconium hydroxide, 2.5 grams of La 2 O 3 , 1.8 grams of strontium nitrate, 8.5 grams of potassium silicate, 5 grams of polystyrene microspheres and 4 grams of hydroxyethyl cellulose were mixed and pulverized in a pulverizer for 20 minutes, and stirred with a kneader after adding 30 grams of deionized water Knead for 70 minutes, extrude the viscous paste and cut into pellets to make Φ1×(1~3)mm particles, dry at 120°C for 10 hours, and then bake at 800°C for 4 hours in an air atmosphere to obtain Finished catalyst S1. The composition of catalyst S1 is listed in Table 2. Put 30ml of catalyst into the reactor, under reaction conditions: temperature is 630°C, liquid hourly volume space velocity is 1.0h -1 , the water-to-hydrocarbon ratio was 1.6, and the pressure was under normal pressure ...

Embodiment 2

[0070] Prepare catalyst by the method for embodiment 1, difference is to take by weighing 40.7 gram iron oxide red Fe 2 O 3 , 20.3 grams of iron oxide yellow Fe 2 O 3 ·H 2 O, 16.1 grams of potassium carbonate, 7 grams of CeO 2 , 5 grams of CaO, 7.8 grams of zirconium hydroxide, 2.5 grams of La 2 O 3, 1.8 grams of strontium nitrate, 8.5 grams of sodium silicate, 5 grams of polystyrene microspheres and 4 grams of hydroxyethyl cellulose were mixed and pulverized in a pulverizer for 20 minutes, and stirred with a kneader after adding 30 grams of deionized water Knead for 70 minutes, extrude the viscous paste and cut into pellets to make Φ1×(1~3)mm particles, dry at 120°C for 10 hours, and then bake at 800°C for 4 hours in an air atmosphere to obtain Finished catalyst S2. The composition of catalyst S2 is listed in Table 2. Put 30ml of catalyst into the reactor, under reaction conditions: temperature is 630°C, liquid hourly volume space velocity is 1.0h -1 , the water-to-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com