Auxiliary paint for steel ring of automobile hub

A technology for automobile wheels and steel rims, applied in coatings, polyester coatings, polyamide coatings, etc., can solve problems such as high manufacturing costs, dangerous use, cracking of paint surfaces, etc., and achieve non-toxic, non-polluting costs and long service life Increased, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

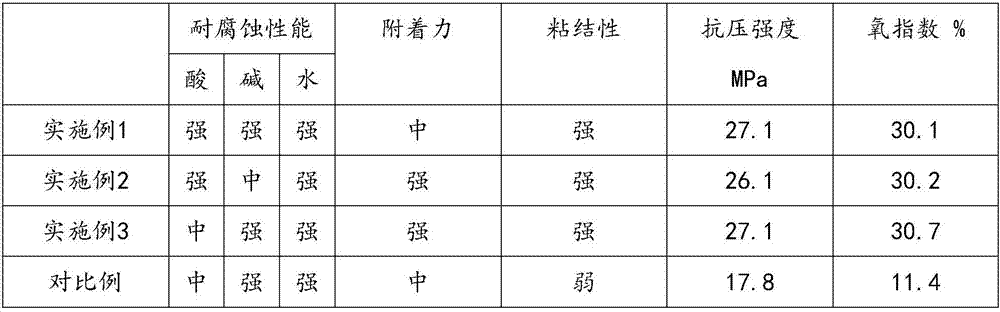

Examples

Embodiment 1

[0025] An auxiliary paint for steel rings of automobile wheels, characterized in that: it is made of the following materials by weight,

[0026] 11 parts of resin, 6 parts of phenol, 4 parts of dicumyl peroxide, 125 parts of nylon, 4 parts of accelerator DM, 1 part of polyester acrylate, 1 part of triethanolamine, 6 parts of modified fluorite, 1 part of bamboo charcoal, six 5 parts of methylene tetramine, 2 parts of tetramethoxymethyl glycoluril, 8 parts of defoamer, 8 parts of anti-aging agent, 5 parts of biomass auxiliary materials, 20 parts of deionized water;

[0027] The resin is one of polyethylene resin, alkyd resin, epoxy resin, urea-formaldehyde resin, polyamide resin;

[0028] The anti-aging agent is one of anti-aging agent AW, anti-aging agent RD, anti-aging agent A, anti-aging agent D, and anti-aging agent CPPD;

[0029] The defoamer is one of emulsified silicone oil, higher alcohol fatty acid ester complex, polyoxyethylene polyoxypropylene pentaerythritol ether, ...

Embodiment 2

[0040] An auxiliary paint for steel rings of automobile wheels, characterized in that: it is made of the following materials by weight,

[0041] 17 parts of resin, 10 parts of phenol, 9 parts of dicumyl peroxide, 1210 parts of nylon, 9 parts of accelerator DM, 5 parts of polyester acrylate, 3 parts of triethanolamine, 12 parts of modified fluorite, 6 parts of bamboo charcoal, six 10 parts of methylene tetramine, 8 parts of tetramethoxymethyl glycoluril, 15 parts of defoamer, 15 parts of anti-aging agent, 10 parts of biomass auxiliary materials, 27 parts of deionized water;

[0042] The resin is one of polyethylene resin, alkyd resin, epoxy resin, urea-formaldehyde resin, polyamide resin;

[0043]The anti-aging agent is one of anti-aging agent AW, anti-aging agent RD, anti-aging agent A, anti-aging agent D, and anti-aging agent CPPD;

[0044] The defoamer is one of emulsified silicone oil, higher alcohol fatty acid ester complex, polyoxyethylene polyoxypropylene pentaerythrito...

Embodiment 3

[0055] An auxiliary paint for steel rings of automobile wheels, characterized in that: it is made of the following materials by weight,

[0056] 14 parts of resin, 8 parts of phenol, 7 parts of dicumyl peroxide, 129 parts of nylon, 6 parts of accelerator DM, 4 parts of polyester acrylate, 2 parts of triethanolamine, 7 parts of modified fluorite, 4 parts of bamboo charcoal, six 8 parts of methylenetetramine, 6 parts of tetramethoxymethyl glycoluril, 11 parts of defoamer, 13 parts of anti-aging agent, 7 parts of biomass auxiliary materials, 24 parts of deionized water;

[0057] The resin is one of polyethylene resin, alkyd resin, epoxy resin, urea-formaldehyde resin, polyamide resin;

[0058] The anti-aging agent is one of anti-aging agent AW, anti-aging agent RD, anti-aging agent A, anti-aging agent D, and anti-aging agent CPPD;

[0059] The defoamer is one of emulsified silicone oil, higher alcohol fatty acid ester complex, polyoxyethylene polyoxypropylene pentaerythritol eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com