Waterproof shell of lead storage battery

A waterproof casing, lead-acid battery technology, applied in the direction of household components, applications, household appliances, etc., can solve the problems of easy external rupture, damage, battery damage, battery use, etc., and achieve the effect of low cost, increased service life, and reasonable method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

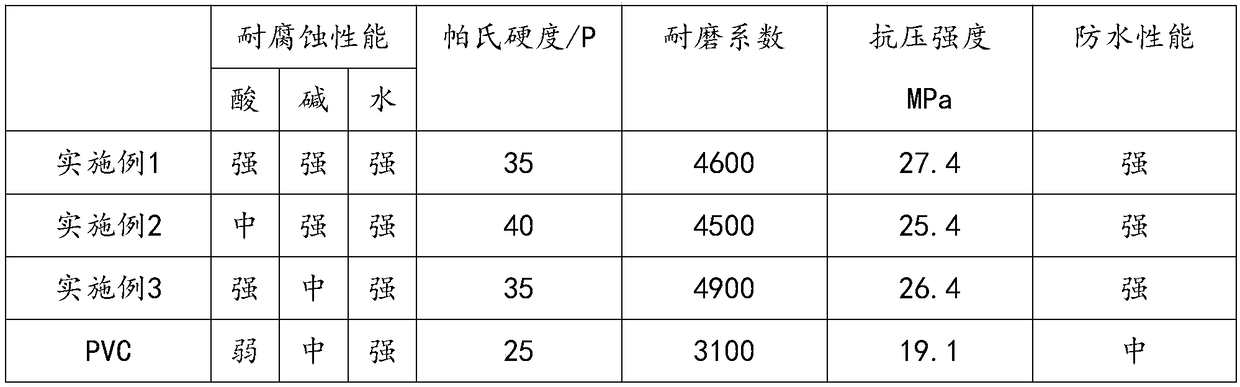

Embodiment 1

[0028] A waterproof casing for a lead storage battery, characterized in that: it is made of the following materials by weight,

[0029] 40 parts of polypropylene, 10 parts of modified nano calcium carbonate, 4 parts of mica powder, 1 part of poly-4-methyl-1-pentene, 2 parts of diethylene glycol benzoate, 9 parts of polyvinyl chloride resin 1 part, 1 part of isopropyl distearoyloxyaluminate, 2 parts of vinyl triethoxysilane, 2 parts of chlorinated paraffin, 9 parts of auxiliary agent, 12 parts of anti-aging agent, 35 parts of water;

[0030] The preparation method of the modified calcium carbonate is as follows: the nano-calcium carbonate is made into a slurry with a mass fraction of 10-14%, the temperature is raised to 80-90°C, the speed of the emulsifier is adjusted to 5000-6000r / min, and 2 -3% aluminate coupling agent DL-411, keep warm for 20-30min, filter, wash with distilled water, then add poly-4-methyl-1-pentene, stir and mix for 20-30min, then in 100-110 Dry at ℃ and p...

Embodiment 2

[0046] A waterproof casing for a lead storage battery, characterized in that: it is made of the following materials by weight,

[0047] 50 parts of polypropylene, 15 parts of modified nano calcium carbonate, 12 parts of mica powder, 6 parts of poly-4-methyl-1-pentene, 7 parts of diethylene glycol benzoate, 14 parts of polyvinyl chloride resin 4 parts, 4 parts of isopropyl distearoyloxyaluminate, 7 parts of vinyl triethoxysilane, 9 parts of chlorinated paraffin, 16 parts of auxiliary agent, 20 parts of anti-aging agent, 42 parts of water;

[0048] The preparation method of the modified calcium carbonate is as follows: the nano-calcium carbonate is made into a slurry with a mass fraction of 10-14%, the temperature is raised to 80-90°C, the speed of the emulsifier is adjusted to 5000-6000r / min, and 2 -3% aluminate coupling agent DL-411, keep warm for 20-30min, filter, wash with distilled water, then add poly-4-methyl-1-pentene, stir and mix for 20-30min, then in 100-110 Dry at ℃...

Embodiment 3

[0064] A waterproof casing for a lead storage battery, characterized in that: it is made of the following materials by weight,

[0065] 45 parts of polypropylene, 13 parts of modified nano calcium carbonate, 9 parts of mica powder, 2 parts of poly-4-methyl-1-pentene, 6 parts of diethylene glycol benzoate, 11 parts of polyvinyl chloride resin 2 parts, 2 parts of isopropyl distearoyloxyaluminate, 5 parts of vinyl triethoxysilane, 7 parts of chlorinated paraffin, 12 parts of auxiliary agent, 18 parts of anti-aging agent, 39 parts of water;

[0066] The preparation method of the modified calcium carbonate is as follows: the nano-calcium carbonate is made into a slurry with a mass fraction of 10-14%, the temperature is raised to 80-90°C, the speed of the emulsifier is adjusted to 5000-6000r / min, and 2 -3% aluminate coupling agent DL-411, keep warm for 20-30min, filter, wash with distilled water, then add poly-4-methyl-1-pentene, stir and mix for 20-30min, then in 100-110 Dry at ℃ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com