A gas-phase process for the separation of ethylbenzene and/or propylbenzene from gas containing ethylene and/or propylene

A technology of propylene gas and gas phase method, which is applied in the product separation process field of producing ethylbenzene and/or propylbenzene from gas containing ethylene and/or propylene gas in the gas phase method, can solve the problem of high energy consumption in the separation process, and achieve low energy consumption and smooth flow process Simple, low-investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

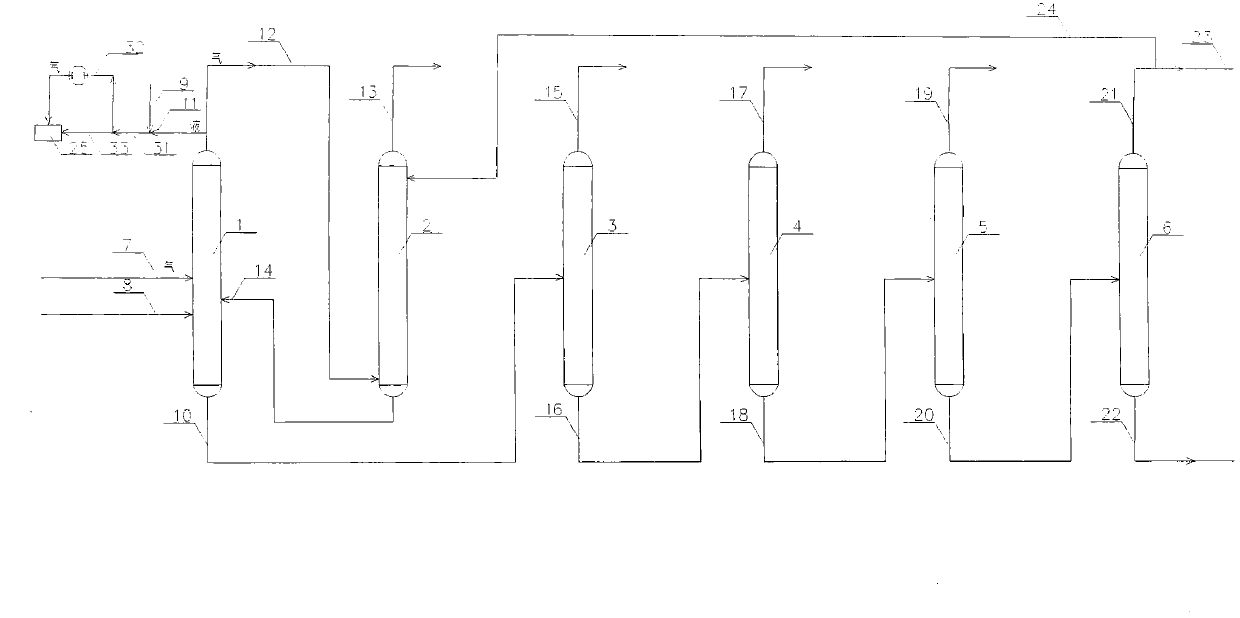

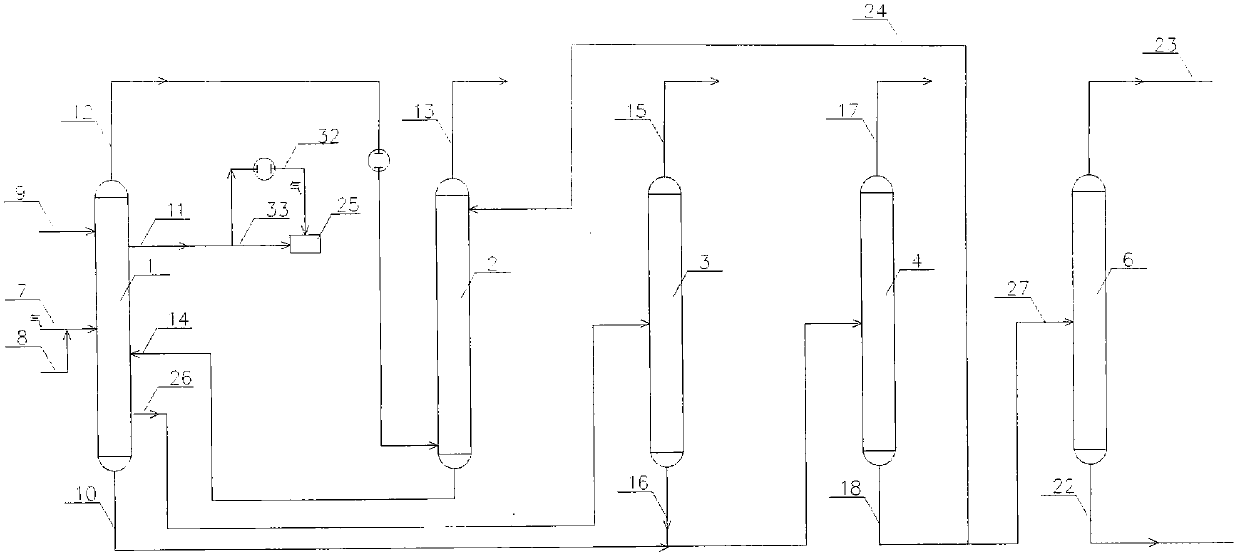

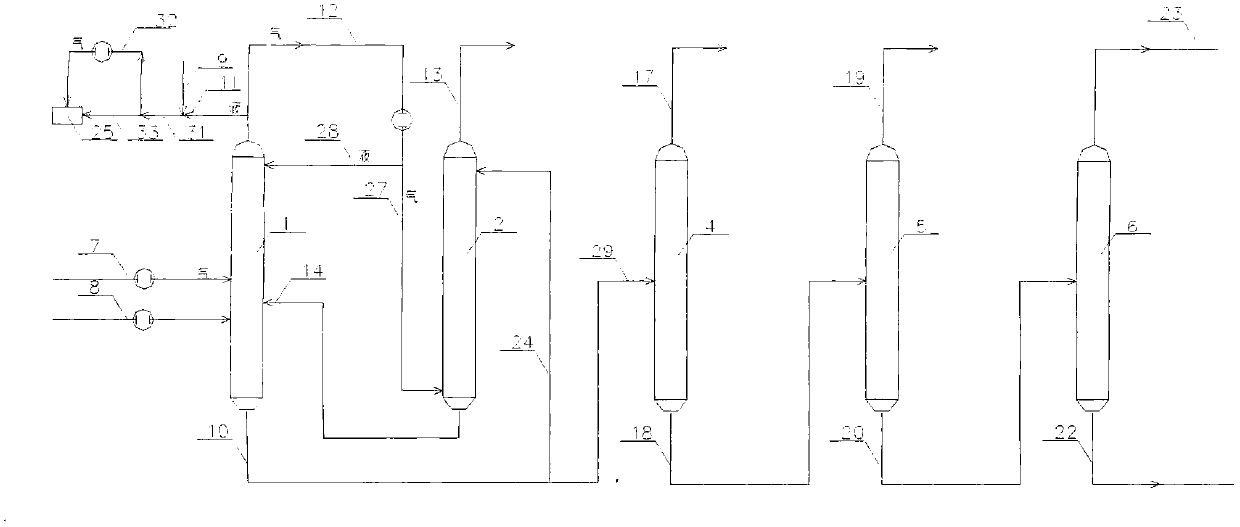

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the specific embodiments do not limit the scope of protection claimed by the present invention.

[0061] A specific embodiment of the present invention is as figure 1 As shown, the gas-phase alkylation reaction product 7 and anti-alkylation reaction product 8 enter the benzene tower 1 respectively, and the gas phase material 12 at the top of the benzene tower goes to the absorption tower, and is in reverse contact with the circulating absorbent 24 in the absorption tower, and the tower top material is the reaction Tail gas 13, absorption tower bottom material 14 returns to benzene tower 1; benzene tower upper liquid phase material 11 is drawn out from the top of the tower, mixed with fresh benzene 9 to form reaction benzene 31, reaction benzene 31 is divided into two parts, one of which is hydrocarbon Benzene 32 is used for chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com