Supported urushibara nickel catalyst and preparation method thereof

A lacquer original nickel and catalyst technology, which is applied in the field of supported lacquer original nickel catalyst and its preparation, can solve the problems of low catalytic strength, small specific surface area, and unreported research, and achieve increased catalyst strength, excellent hydrogenation performance, and specific surface area. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

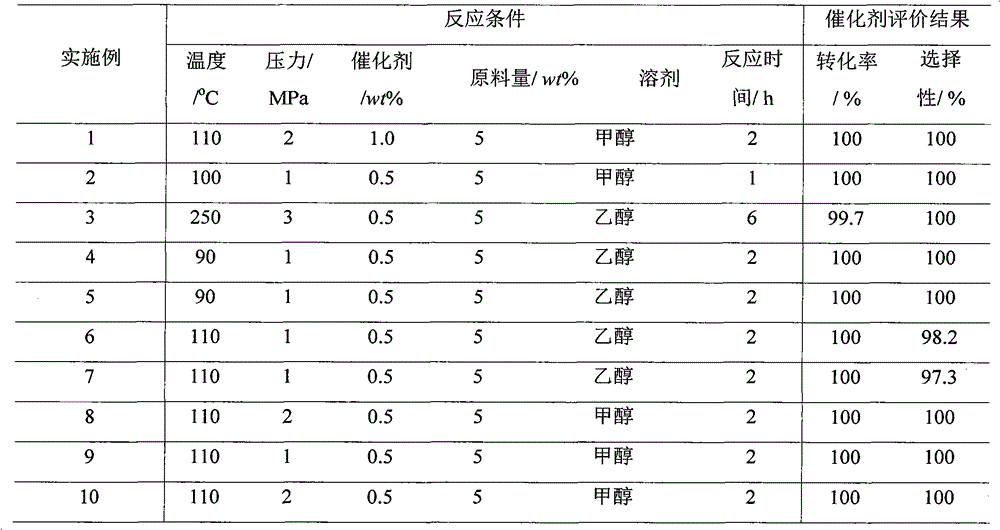

Examples

Embodiment 1

[0027] Carrier pretreatment: 60-80 mesh SiO 2 Dry at 110°C for 10 hours to remove the moisture in the carrier.

[0028] ·Impregnation: according to the Fe load of 40wt%, using the equal volume impregnation method, put the dried carrier into FeCl 3 solution, and soaked at 40 ° C for 20 h under stirring conditions.

[0029] ·Drying and roasting: put the impregnated sample into an oven and dry at 110°C for 5h, grind the dried powder and place it in a muffle furnace and roast at 350°C for 3h to obtain Fe 2 o 3 / SiO 2 Prebody.

[0030] Hydrogen reduction: Fe 2 o 3 / SiO 2 Composition in volume is 5% H 2 with 95%N 2 Fe / SiO was obtained after reduction at 550°C for 12 hours in a mixed atmosphere 2 .

[0031] Reduction reaction: preparation of NiCl 2 solution, the prepared Fe / SiO 2 Dispersed in water to obtain Fe / SiO 2 Suspension, control Fe / Ni 2+ =4, then the NiCl 2 Solution added to Fe / SiO 2In the suspension, stir and react at 80°C for 11 hours to obtain a suspension...

Embodiment 2

[0035] Carrier pretreatment: 60-80 mesh SiO 2 Dry at 90°C for 2 hours to remove the moisture in the carrier.

[0036] ·Impregnation: according to the Fe load of 5wt%, using the equal volume impregnation method, put the dried carrier into FeCl 3 solution, and soaked at 40°C for 0.5h under agitation.

[0037] ·Drying and roasting: put the impregnated sample into an oven and dry at 90°C for 5h, grind the dried powder and place it in a muffle furnace and roast at 300°C for 1h to obtain Fe 2 o 3 / SiO 2 Prebody.

[0038] Hydrogen reduction: Fe 2 o 3 / SiO 2 Composition in volume is 10% H 2 with 90% N 2 Fe / SiO was obtained after reduction at 450°C for 12 hours in a mixed atmosphere 2 .

[0039] Reduction reaction: preparation of NiCl 2 with MoCl 2 The mixed solution, in which the amount of Mo added accounted for 4.4wt% of Ni, the prepared Fe / SiO 2 Dispersed in water, control Fe / Ni 2+ = 3, then add the mixed solution of Ni above to Fe / SiO 2 In the suspension, stir and r...

Embodiment 3

[0042] Carrier pretreatment: 80-100 mesh SiO 2 Dry at 100°C for 4 hours to remove the moisture in the carrier.

[0043] ·Impregnation: according to the Fe load of 8wt%, using the equal volume impregnation method, put the dried carrier into FeCl 3 solution, and soaked at 50°C for 4h under agitation.

[0044] Drying and roasting: put the impregnated sample into an oven and dry at 100°C for 6h, grind the dried powder and place it in a muffle furnace and roast at 350°C for 2h to obtain Fe 2 o 3 / SiO 2 Prebody.

[0045] Hydrogen reduction: Fe 2 o 3 / SiO 2 Composition in volume is 15% H 2 with 85% N 2 Fe / SiO was obtained after reduction at 500°C for 10 h in a mixed atmosphere of 2 .

[0046] Reduction reaction: preparation of NiCl 2 with CoCl 2 The mixed solution, wherein the addition of Zr accounted for 3wt% of Co, the prepared Fe / SiO 2 Dispersed in water, control Fe / Ni 2+ = 4, then the mixed solution of Ni above was added to Fe / SiO 2 In the suspension, stir and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com