Light alkane isomerized ionic liquid catalyst and preparation method thereof

An ionic liquid, light alkane technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of low isomer selectivity, etc. The effect of improving selectivity and liquid yield, increasing octane number, and suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0036] A kind of preparation method of light alkane isomerization ionic liquid catalyst with product distribution optimization function described in this embodiment comprises the following steps:

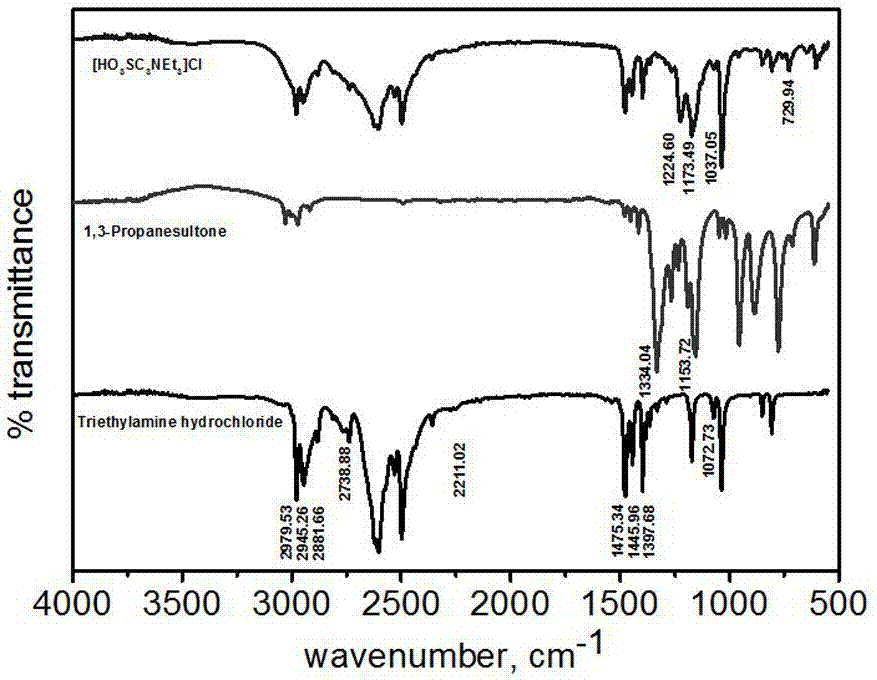

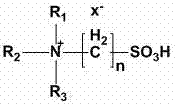

[0037] (1) Accurately weigh 17.10 g of triethylamine hydrochloride (Triethylamine Hydrochloride) in a 250 mL three-neck flask, add 50 mL of absolute ethanol and stir to dissolve, add 13.77 g of 1,3-propanesulfonate dropwise under a protective atmosphere Acid lactone (1,3-Propanesultone), after stirring evenly, raise the system temperature to 80 o C reflux reaction for 12 hours, remove the solvent ethanol by rotary evaporation, and then separate the unreacted raw materials and products by centrifugation to obtain the quaternary ammonium chloride ionic liquid intermediate with sulfonate [HO 3 SC 3 NET 3 ] Cl.

[0038] (2) Accurately weigh 4.50 g of the quaternary ammonium chloride ionic liquid intermediate [HO 3 SC 3 NET 3 ]Cl in a 100 mL three-neck flask, under a protective atm...

Embodiment 1-2

[0043] A kind of preparation method of light alkane isomerization ionic liquid catalyst with product distribution optimization function described in this embodiment comprises the following steps:

[0044] (1) Accurately weigh 17.10 g of triethylamine hydrochloride (Triethylamine Hydrochloride) in a 250 mL three-neck flask, add 50 mL of anhydrous methanol to fully stir to dissolve, and add 13.77 g of 1,3-propanesulfonate dropwise under a protective atmosphere Acid lactone (1,3-Propanesultone), after stirring evenly, raise the system temperature to 90 o C was refluxed for 8 hours, and the solvent methanol was removed by rotary evaporation, and then the unreacted raw material was separated from the product by centrifugation to obtain the quaternary ammonium chloride ionic liquid intermediate with sulfonate [HO 3 SC 3 NET 3 ] Cl.

[0045] (2) Accurately weigh 4.50 g of the quaternary ammonium chloride ionic liquid intermediate [HO 3 SC 3 NET 3 ]Cl in a 100 mL three-neck flas...

Embodiment 2-1

[0047] The ionic liquid catalyst described in Example 1-1 is used to catalyze the isomerization reaction of light alkanes, specifically comprising the following steps:

[0048] (1) Weigh the ionic liquid according to the mass ratio of ionic liquid catalyst A and n-hexane 1:1 (based on the mass of 10 mL n-hexane).

[0049] (2) Control the initial nitrogen pressure of the autoclave to be 1 MPa, the stirring speed is controlled at 1000 rpm, and the reaction temperature is controlled at 50 o C, reacted for 12 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com