Preparation method of hydroisomerization/cracking catalyst

A cracking catalyst, hydroisomerization technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low yield of target products, affecting economic benefits, and sharp increase in light products. , to achieve excellent isomerization performance, improved material mass transfer, increased diesel content and lube base oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

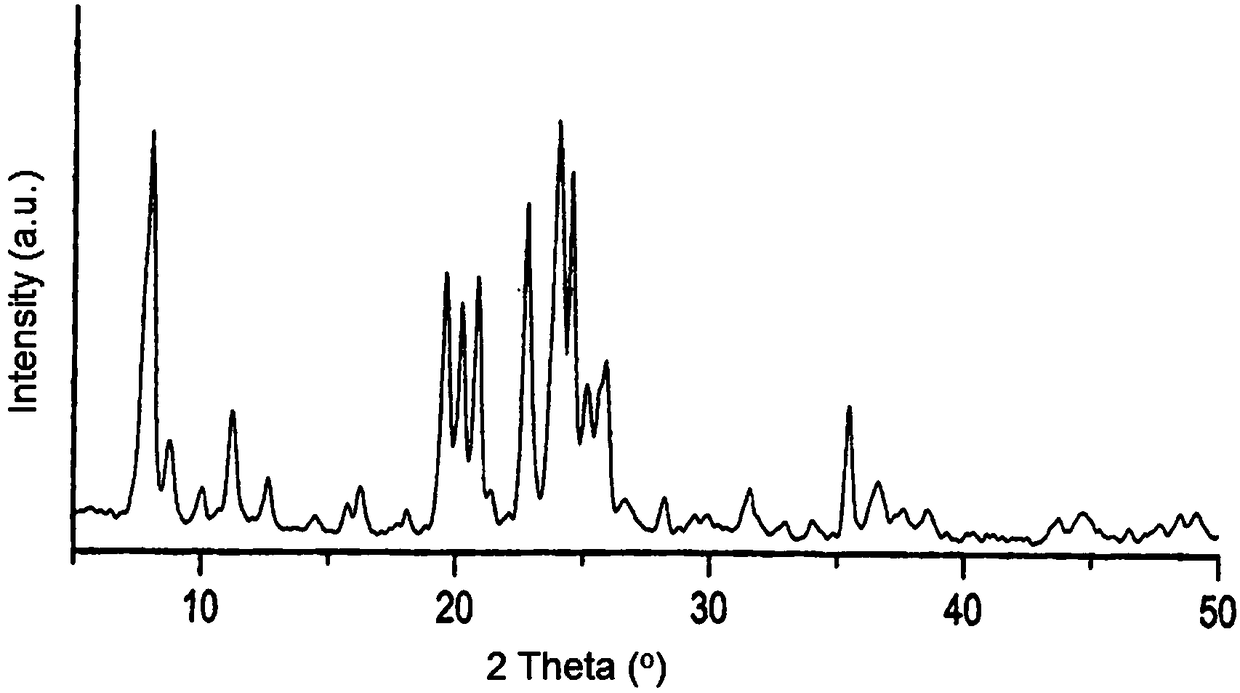

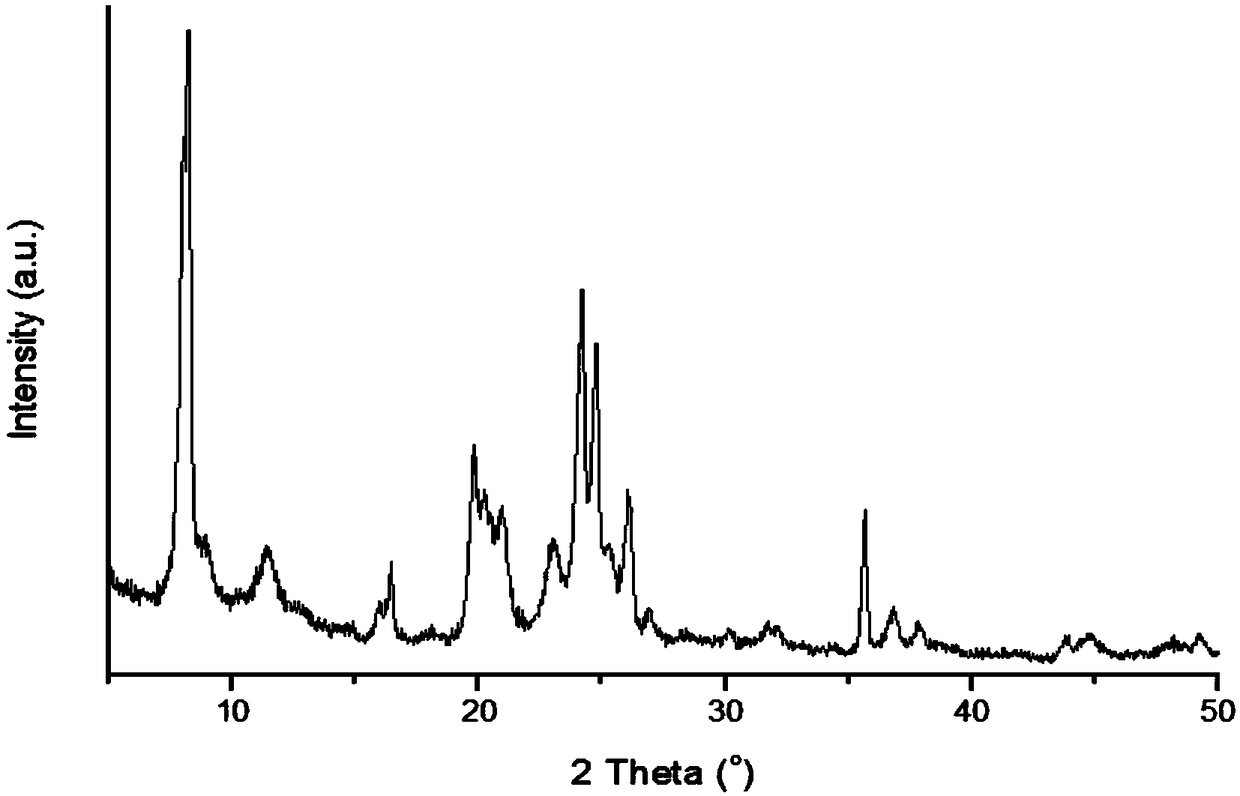

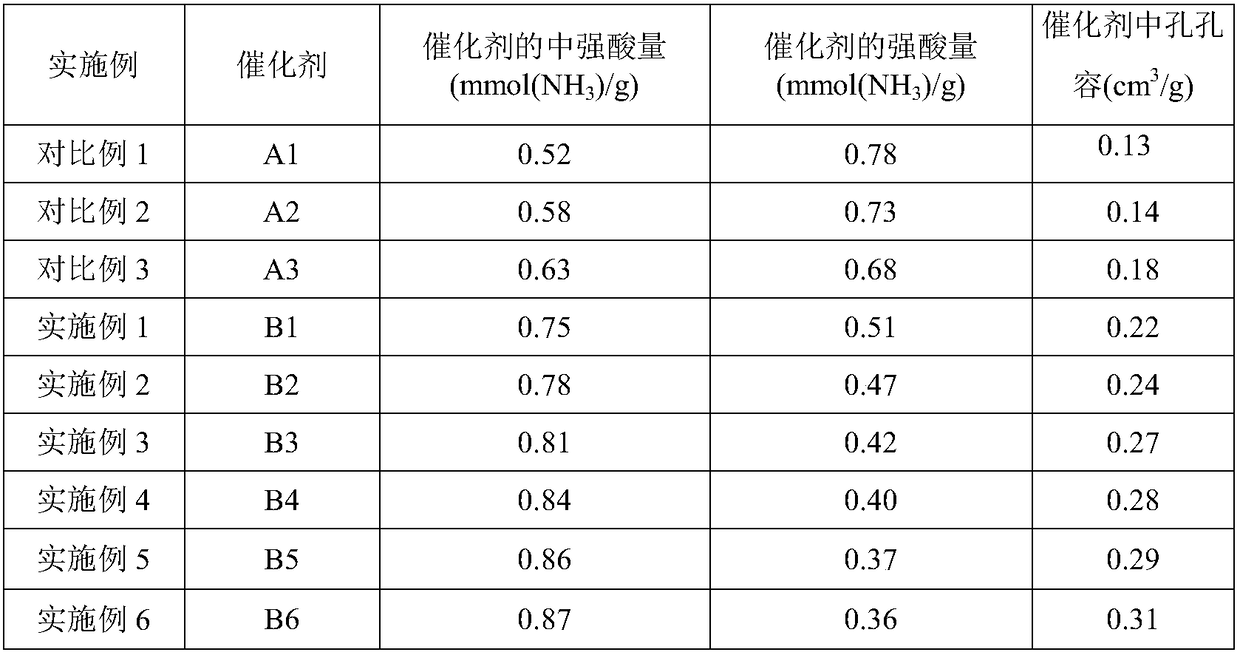

[0059] Synthesis of sodium ZSM-22 / ZSM-23 composite molecular sieves: NaOH, Al 2 (SO 4 ) 3 18H 2 O, dimethylamine, triethylamine, silica sol (SiO 2 The content is 30wt.%), concentrated sulfuric acid (98%) and water are mixed uniformly according to a certain ratio to form a sol system during the synthesis of ZSM-23 molecular sieve, and ZSM-22 molecular sieve is added to the above sol system as a seed crystal to form a mixed Sol system, the specific material composition is as follows: SiO 2 / Al 2 o 3 =70, dimethylamine / SiO 2 =1, triethylamine / SiO 2 = 1, H 2 SO 4 / SiO 2 =0.15,Na 2 O / SiO 2 =0.3, ZSM-23 molecular sieve seed crystal / SiO 2 =0.1,H 2 O / SiO 2 =35; after stirring and mixing evenly, put it into a 1L high-pressure reactor, heat up to 170°C after sealing, and crystallize for 72 hours. Structure-based sodium-type ZSM-22 / ZSM-23 composite molecular sieve containing template. The XRD spectrum of the ZSM-22 / ZSM-23 composite molecular sieve is shown in figure 2 ...

Embodiment 2

[0062] Synthesis of sodium ZSM-22 / ZSM-23 composite molecular sieves: NaOH, Al 2 (SO 4 ) 3 18H 2 O, dimethylamine, triethylamine, silica sol (SiO 2 The content is 30wt.%), concentrated sulfuric acid (98%) and water are mixed uniformly according to a certain ratio to form a sol system during the synthesis of ZSM-23 molecular sieve, and ZSM-22 molecular sieve is added to the above sol system as a seed crystal to form a mixed Sol system, the specific material composition is as follows: SiO 2 / Al 2 o 3 =100, dimethylamine / SiO 2 =0.6, triethylamine / SiO 2 =0.8,H 2 SO 4 / SiO 2 =0.15,Na 2 O / SiO 2 =0.3, ZSM-23 molecular sieve seed crystal / SiO 2 = 2, H 2 O / SiO 2 =35; after stirring and mixing evenly, put it into a 1L high-pressure reactor, heat up to 170°C after sealing, and crystallize for 65 hours. Structure-based sodium-type ZSM-22 / ZSM-23 composite molecular sieve containing template.

[0063] Catalyst preparation: Take 100g of sodium-type ZSM-22 / ZSM-23 composite mole...

Embodiment 3

[0065] Synthesis of sodium ZSM-22 / ZSM-23 composite molecular sieves: NaOH, Al 2 (SO 4 ) 3 18H 2 O, dimethylamine, triethylamine, silica sol (SiO 2 The content is 30wt.%), concentrated sulfuric acid (98%) and water are mixed uniformly according to a certain ratio to form a sol system during the synthesis of ZSM-23 molecular sieve, and ZSM-22 molecular sieve is added to the above sol system as a seed crystal to form a mixed Sol system, the specific material composition is as follows: SiO 2 / Al 2 o 3 =80, dimethylamine / SiO 2 =0.5, triethylamine / SiO 2 =0.5,H 2 SO 4 / SiO 2 =0.10,Na 2 O / SiO 2 =0.4, ZSM-23 molecular sieve seed crystal / SiO 2 =0.2,H 2 O / SiO 2 =35; after stirring and mixing evenly, put it into a 1L high-pressure reactor, heat up to 165°C after sealing, and crystallize for 69 hours. Structure-based sodium-type ZSM-22 / ZSM-23 composite molecular sieve containing template.

[0066] Catalyst preparation: Take 100g of sodium-type ZSM-22 / ZSM-23 composite molec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com