Hydrocarbon catalytic cracking catalyst and its preparation method

A catalytic cracking and catalyst technology, applied in the direction of catalyst activation/preparation, catalytic cracking, physical/chemical process catalysts, etc., can solve the problems of molecular sieve structure damage, poor cracking performance isomerization performance, light oil gasoline yield reduction, etc. , to achieve good light oil yield, high cracking performance and isomerization performance, and the effect of increasing gasoline octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 31.2 liters of water glass (SiO 2 content is 250g / L), 3 liters of n-butylamine (Q), 1.1 liters of aluminum sulfate (Al 2 o 3Content is 90g / L), 0.9 liters of concentration are the concentrated sulfuric acid of 98%, 5 liters of water mix homogeneously, the molar proportion of gained reactant is:

[0030] SiO 2 / Al 2 o 3 =130, Q / Al 2 o 3 =30, Na 2 O / Al 2 o 3 =15,H 2 O / Al 2 o 3 =4000

[0031] Put the above reactants into a crystallization tank and crystallize at 180°C for 24 hours, then filter, wash and dry to obtain the raw molecular sieve powder.

[0032] After the above-mentioned raw powder is roasted at 450°C for 2 hours, under stirring, it is treated with 10% ammonium chloride solution at 90-95°C and a solid-to-liquid ratio of 1:10 for 1 hour, then filtered and washed with water until there is no chloride ion. Repeat the above process 2 more times. Subsequently, after roasting at 600°C for 1 hour, soak for 2 hours with 5% hydrochloric acid solution at 60...

Embodiment 2

[0034] Be prepared with the raw material identical with embodiment 1, the mixture that has following molar ratio:

[0035] SiO 2 / Al 2 o 3 =240, Q / Al 2 o 3 =35, Na 2 O / Al 2 o 3 =20,H 2 O / Al 2 o 3 =4000

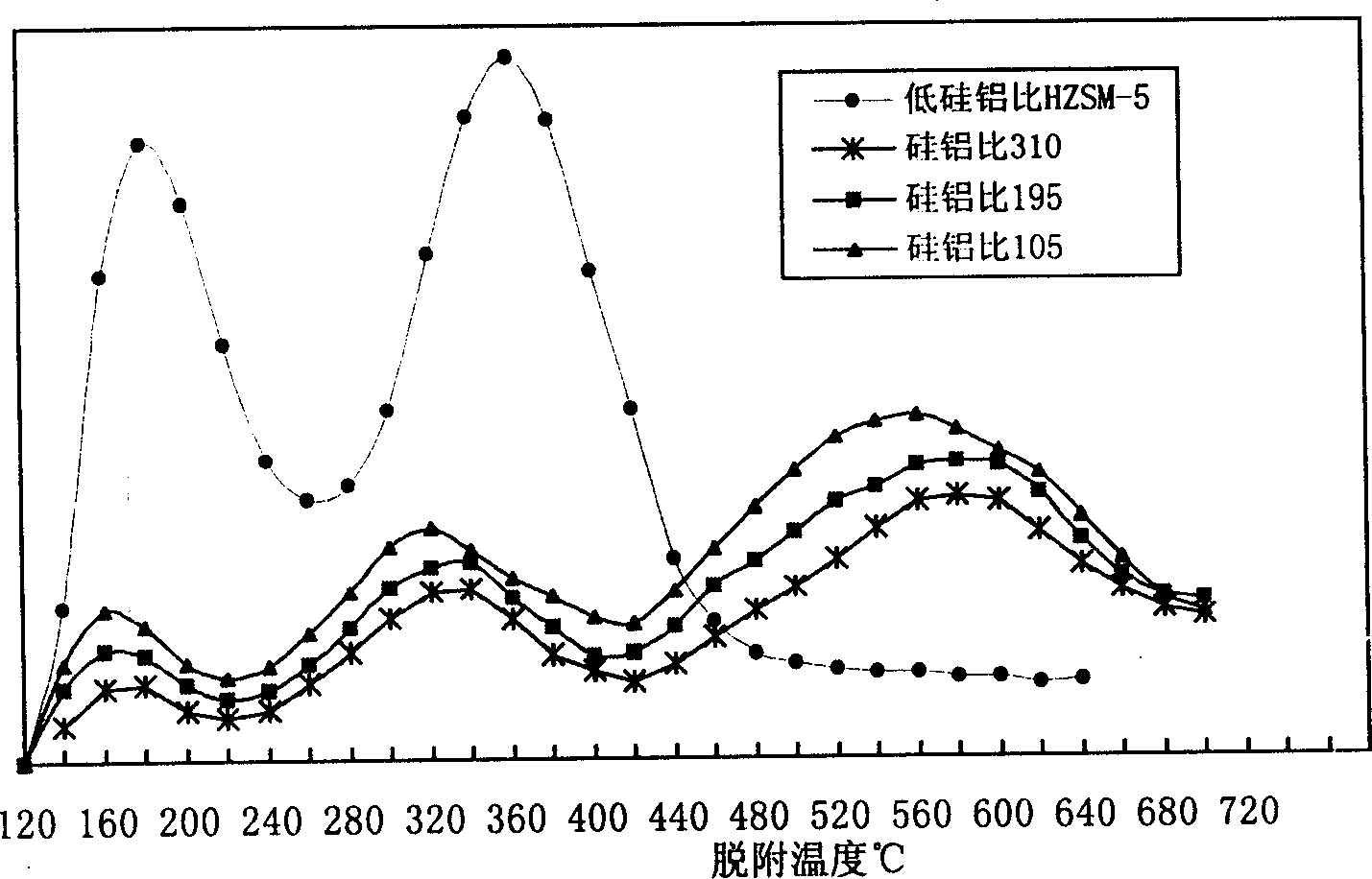

[0036] Put the above reaction mixture into a crystallization tank and crystallize at 170°C for 30 hours, then filter, wash and dry to obtain the raw molecular sieve powder. The modified molecular sieve HZSM-5 was obtained by modifying the above raw powder through the same process as in Example 1. The silicon-aluminum ratio of HZSM-5 is 195, and the total content of heterocrystalline silicon oxide in various crystal forms is 3%.

Embodiment 3

[0038] Be prepared with the raw material identical with embodiment 1, the mixture that has following molar ratio:

[0039] SiO 2 / Al 2 o 3 =380, Q / Al 2 o 3 =40,Na 2 O / Al 2 o 3 =18,H 2 O / Al 2 o 3 =4500

[0040] The above reaction mixture was put into a crystallization tank and crystallized at 170°C for 40 hours, filtered, washed and dried to obtain the molecular sieve powder. The modified molecular sieve HZSM-5 was obtained by modifying the above raw powder through the same process as in Example 1. The ratio of silicon to aluminum of HZSM-5 is 310, and the total content of heterocrystalline silicon oxide in various crystal forms is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com