Wear-resisting foil type dynamic pressure thrust gas bearing and manufacturing method

A gas bearing and foil technology, which is applied in the field of wear-resistant foil type dynamic pressure thrust gas bearing and its preparation, can solve the problems of inability to meet the requirements of start-stop life, improve lubrication performance, prolong start-stop life, and reduce friction damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

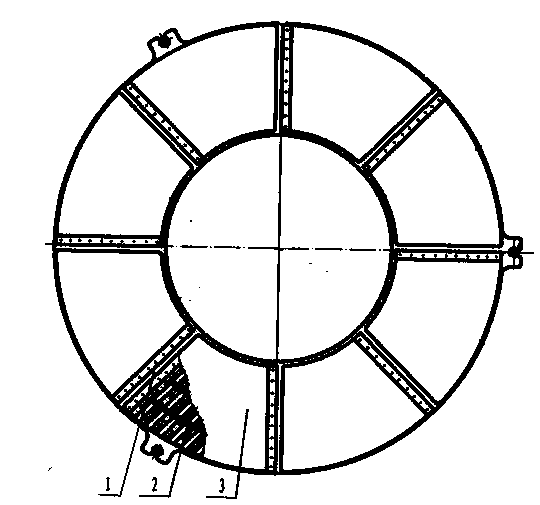

[0017] Wear-resistant foil type dynamic pressure thrust gas bearing of the present invention such as figure 1 As shown, it consists of bottom plate 1, wave foil 2 and top foil 3. The corrugated foil and the top foil are welded on the bottom plate, the number of corrugated foils and top foils is 8, and the material of the top foil is nickel-based superalloy. The top foil is coated with a lubricating coating of nickel-coated graphite particles. The thickness of the coating is 0.051mm. The mass fraction of nickel and graphite in the nickel-coated graphite particles is 7:3, and the particle size of the nickel-coated graphit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com