Smooth feeding door frame assembly for forklift and forklift applying smooth feeding door frame assembly

A material feeding and forklift technology, which is applied in the field of smooth feeding gantry assembly for forklifts, can solve problems such as overturning, and achieve the effects of high safety factor, high degree of automation, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

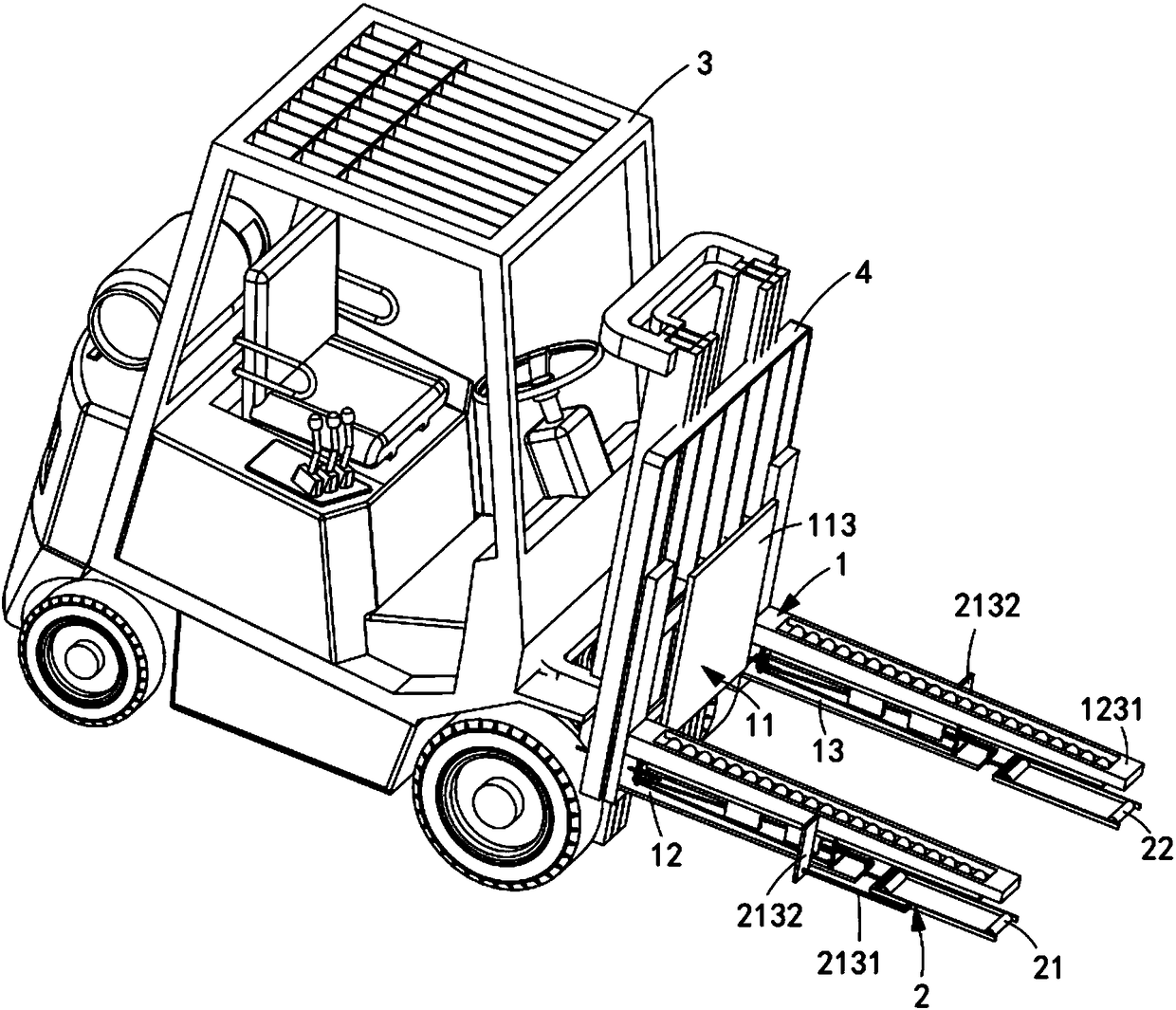

[0062] Such as figure 1 As shown, a smooth feeding gantry assembly for a forklift, including a lifting frame 4, also includes:

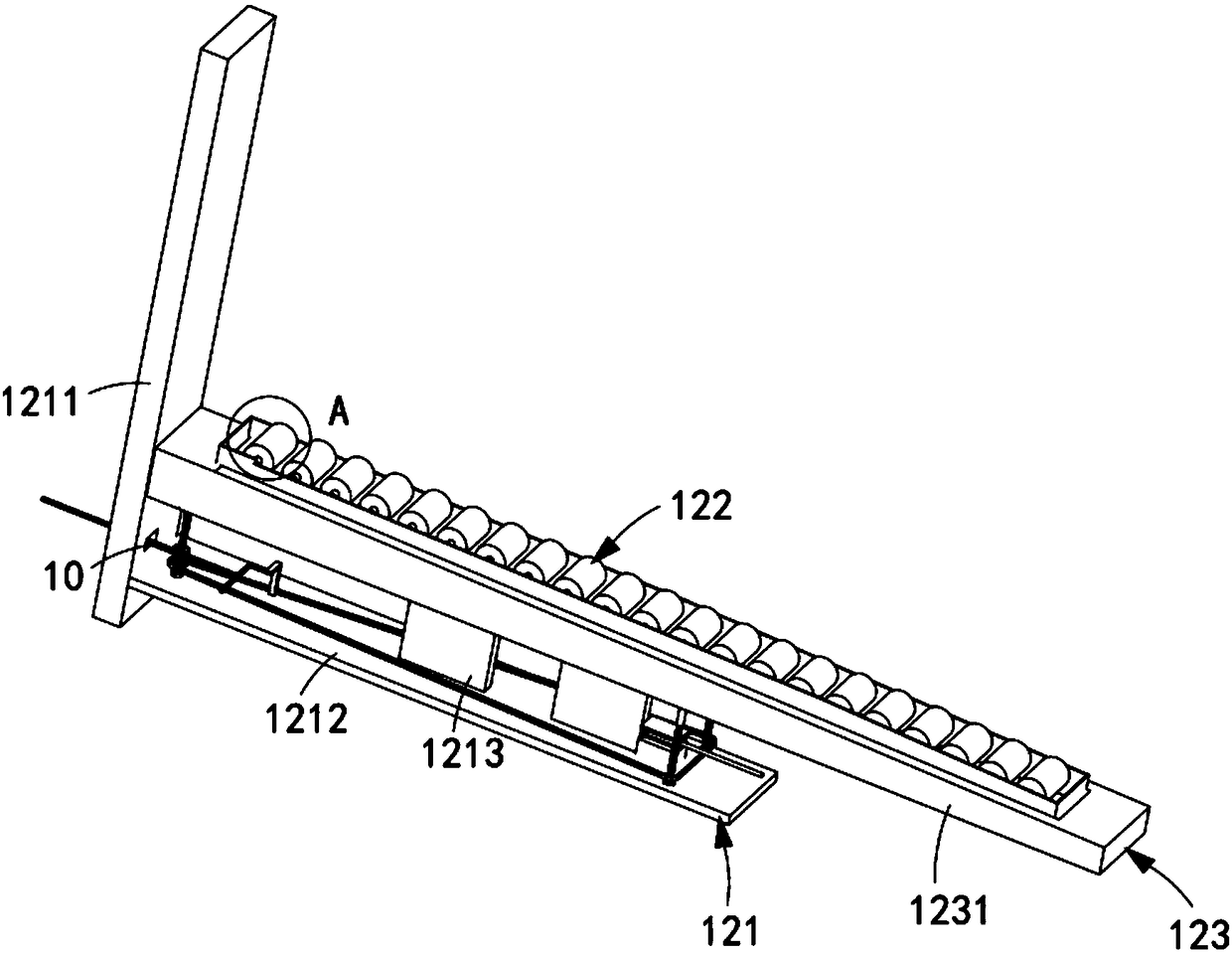

[0063] The primary unloading mechanism 1, the preliminary unloading mechanism 1 includes a driving assembly 11 fixedly arranged in the middle of the lifting frame 4, symmetrically arranged on both sides of the driving assembly 11 and slidingly arranged on the lifting frame 4 The first pusher assembly 12 and the second pusher assembly 13, the drive assembly 11 cooperates with the first pusher assembly 12 and the second pusher assembly 13 for preliminary unloading; and

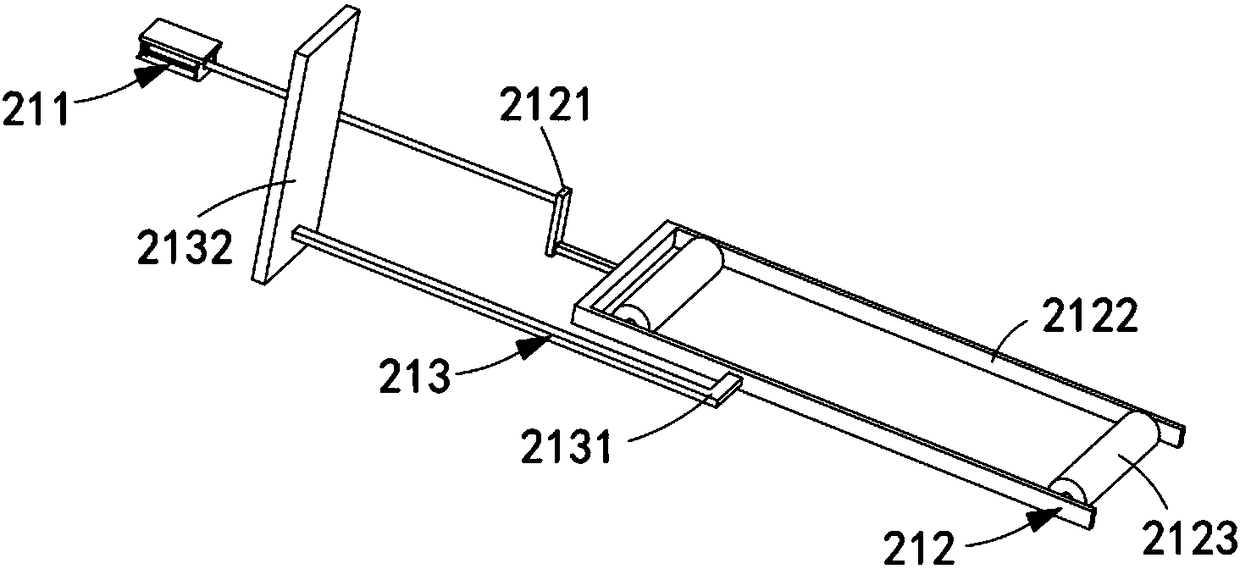

[0064] The secondary unloading mechanism 2, the secondary unloading mechanism 2 includes the first feeding assembly 21 arranged at the lower part of the first pushing assembly 12 and located in the second half of the material conveying direction and the second pushing assembly arranged at the second half The second feeding assembly 22 at the lower part of the feeding assembly 13 and l...

Embodiment 2

[0107] Such as figure 1 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0108]This embodiment also discloses a forklift, which includes a forklift 3 and a smooth feeding mast assembly for a forklift as described in Embodiment 1. The forklift 3 is fixedly connected to the lifting frame 4, and the lifting The frame 4 is located in front of the forklift 3 .

[0109] work process:

[0110] First start the first horizontal push cylinder 111, the first horizontal push cylinder 111 drives the pusher plate 113 to move forward, the drive rack 1239 drives the gear 1238 to rotate, and the screw rod 1235 coaxially arranged with the gear 1238 rotates synchronously. The coaxial sprocket 1237 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com