Multi-stage elastic supporting assembly and dynamic pressure gas radial bearing

An elastic support and component technology, applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of uncertain impact, limited support rigidity, small bubble volume, etc., to reduce friction damage and structural damping. The effect of small and enlarged heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

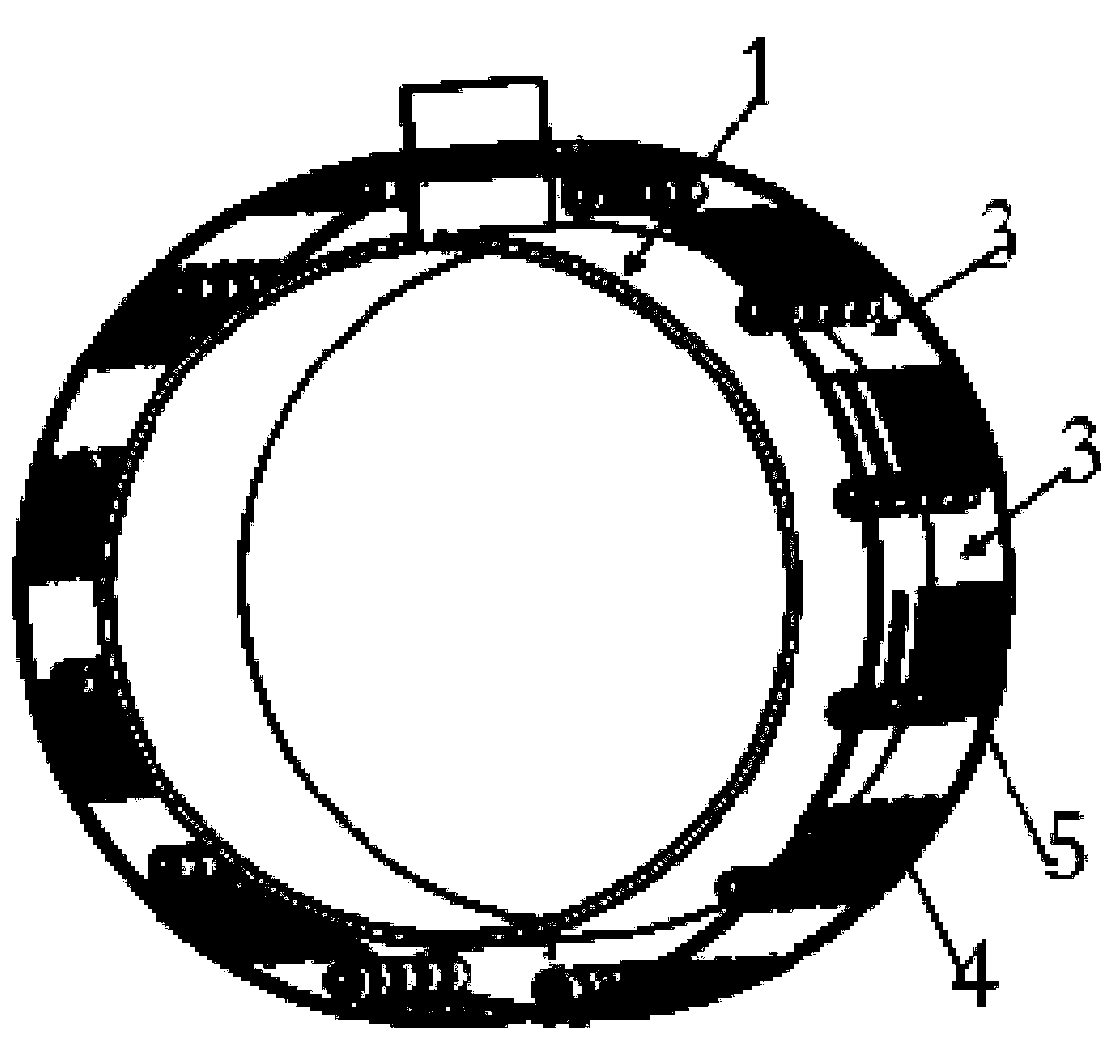

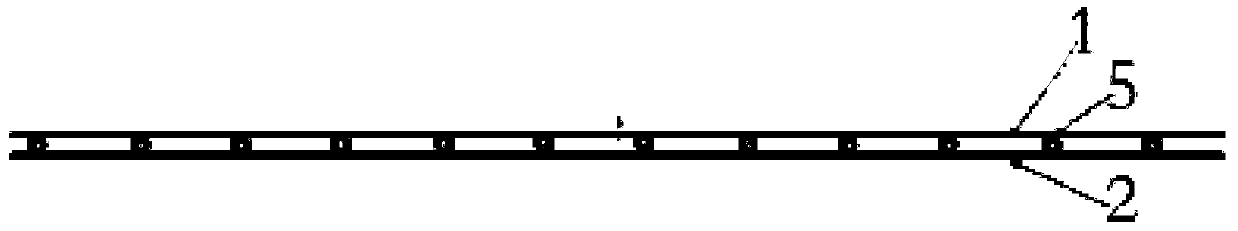

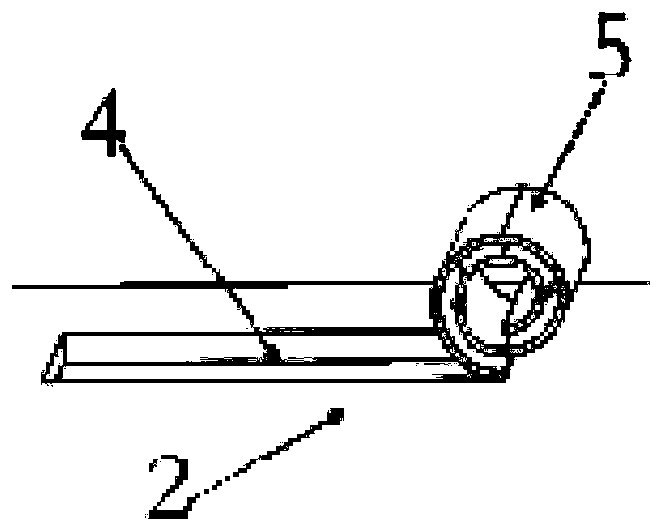

[0033] Hereinafter, specific embodiments of the present application will be described in detail with reference to the accompanying drawings. According to these detailed descriptions, those skilled in the art can clearly understand the present application and can implement the present application. Without departing from the principle of the present application, the features in different embodiments can be combined to obtain new implementations, or some features in certain embodiments can be replaced to obtain other preferred implementations.

[0034] Gas lubrication technology originated in the middle of the 19th century. As a non-contact, high-speed, low-power, and high-precision support technology, gas-lubricated bearings are widely used in rotating machinery such as centrifuges, compressors, fans, and pumps, especially in ultra-high temperature , ultra-low temperature and strong radiation and other special conditions. As an important branch of gas dynamic pressure lubricatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com