Constant-section ultrathin-wall bearing seal structure

A technology of bearing sealing and ultra-thin wall, which is applied in the direction of ball bearings, bearing components, shafts and bearings, etc., can solve the problems of uneven bearing friction torque, poor sealing effect, difficult measurement and control of inclined plane machining, and achieve sealing Uniformity, reduction of starting friction torque, and increase of operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation, structure, Features and features, detailed as follows.

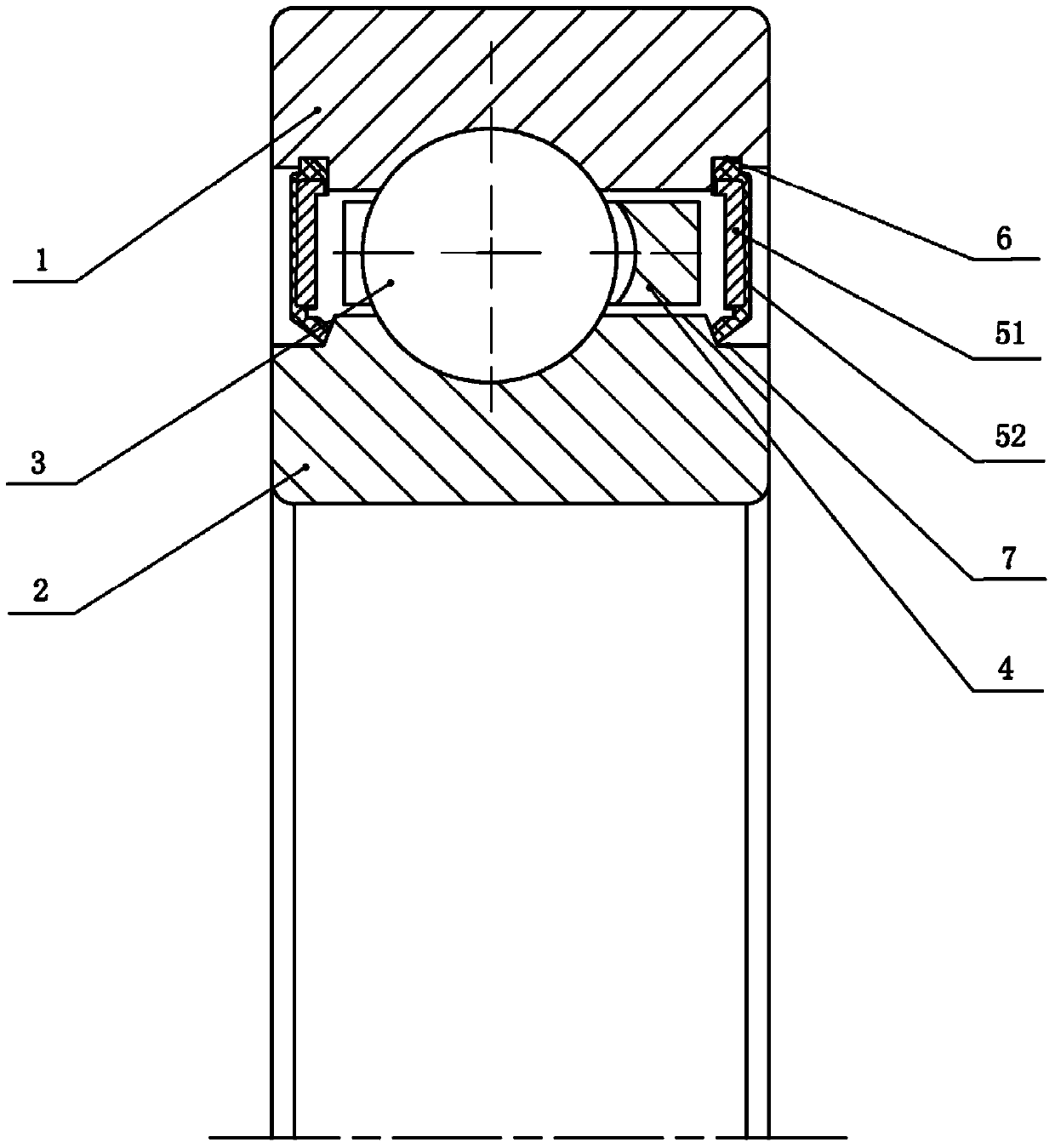

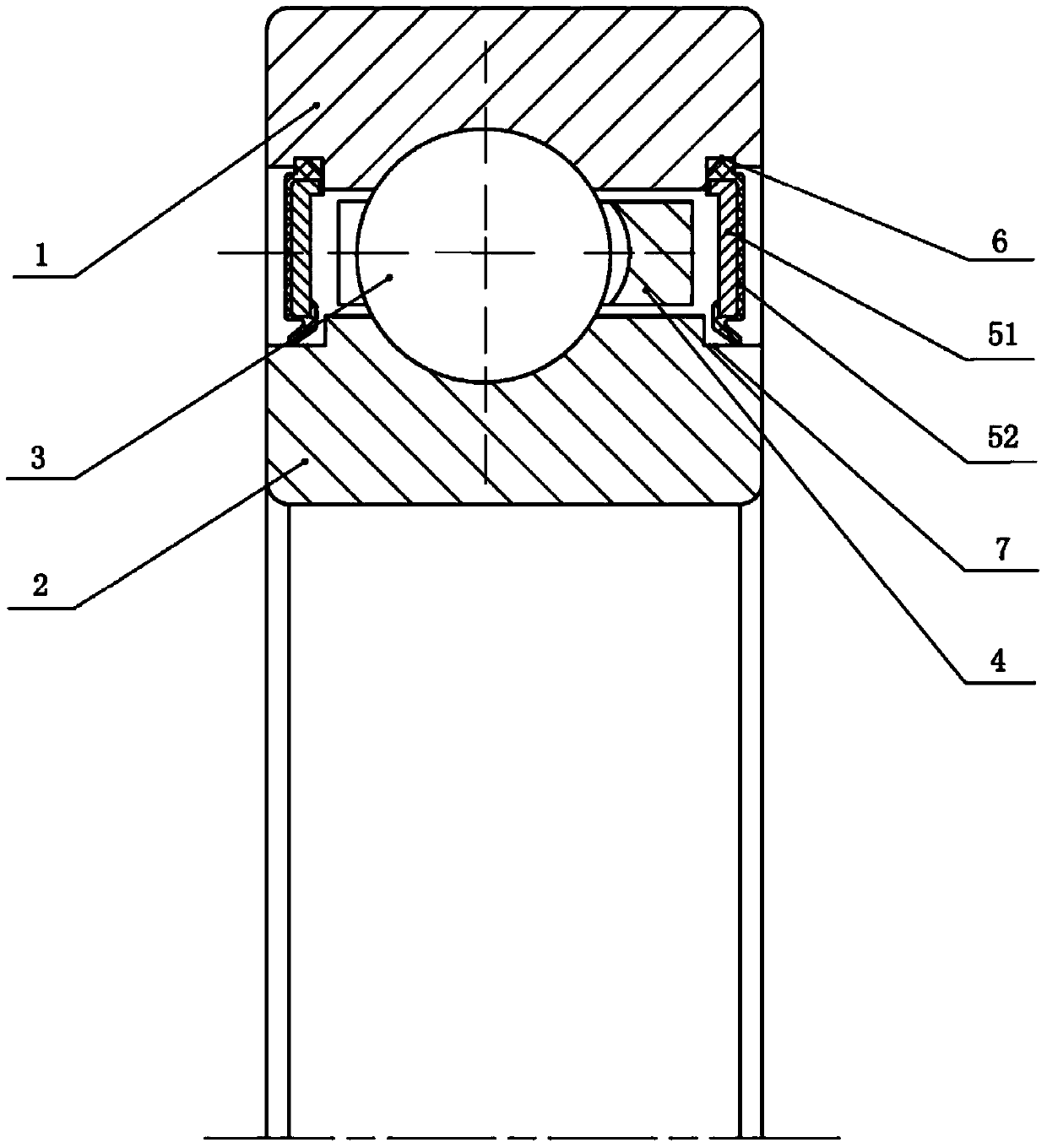

[0023] see figure 2 As shown, it is a schematic diagram of the sealing structure of an equal-section ultra-thin-wall bearing in the present invention, including: outer ring 1, inner ring 2, rolling element 3, cage 4, first sealing ring 51, second sealing ring 52, outer ring teeth 6 And the boss step 7 of the inner ring, wherein, the rolling body 3 is arranged in the channel between the outer ring 1 and the inner ring 2, the rolling body 3 is fixed by the cage 4, and the inner diameter of the outer ring 1 is provided with a symmetrical outer ring The tooth mouth 6, the outer diameter of the inner ring 2 is provided with a symmetrical inner ring boss step 7, and the first sealing ring 51 is sandwiched between the outer ring tooth mouth 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com