Axial small-hole normal-pressure water supply dynamic-static pressure spiral groove thrust bearing

A thrust bearing and spiral groove technology, applied in the field of thrust bearings, can solve problems such as increased bearing wear, blocked lubricating medium, poor bearing water, etc., and achieve the effects of optimizing bearing performance, improving dynamic pressure bearing capacity, and sufficient water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

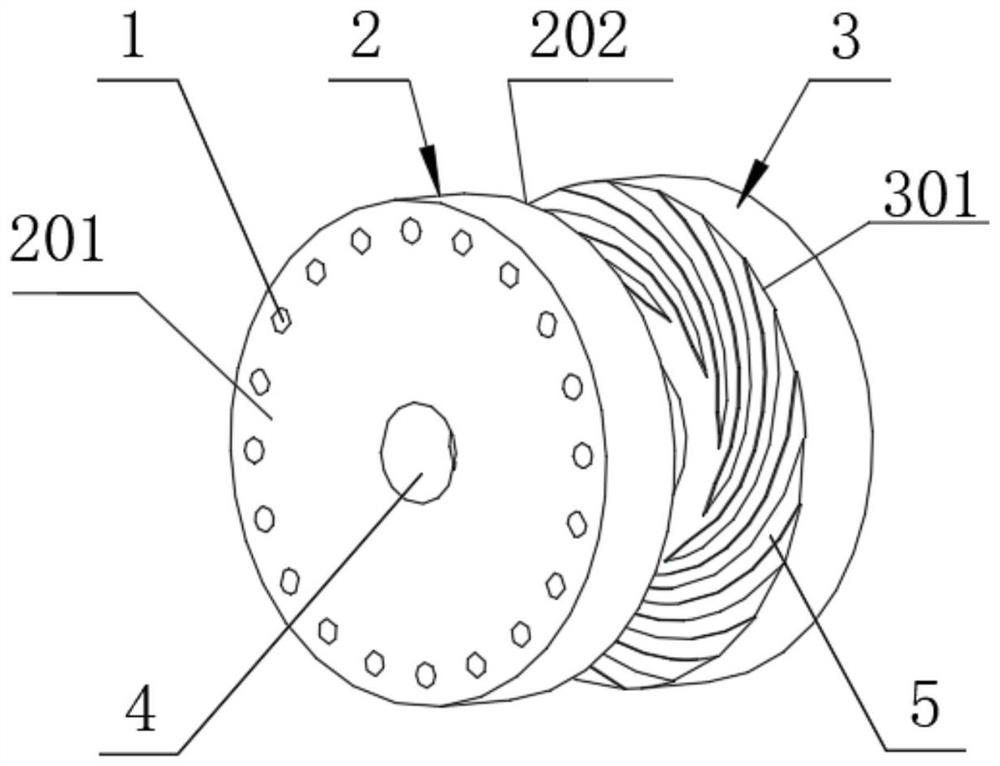

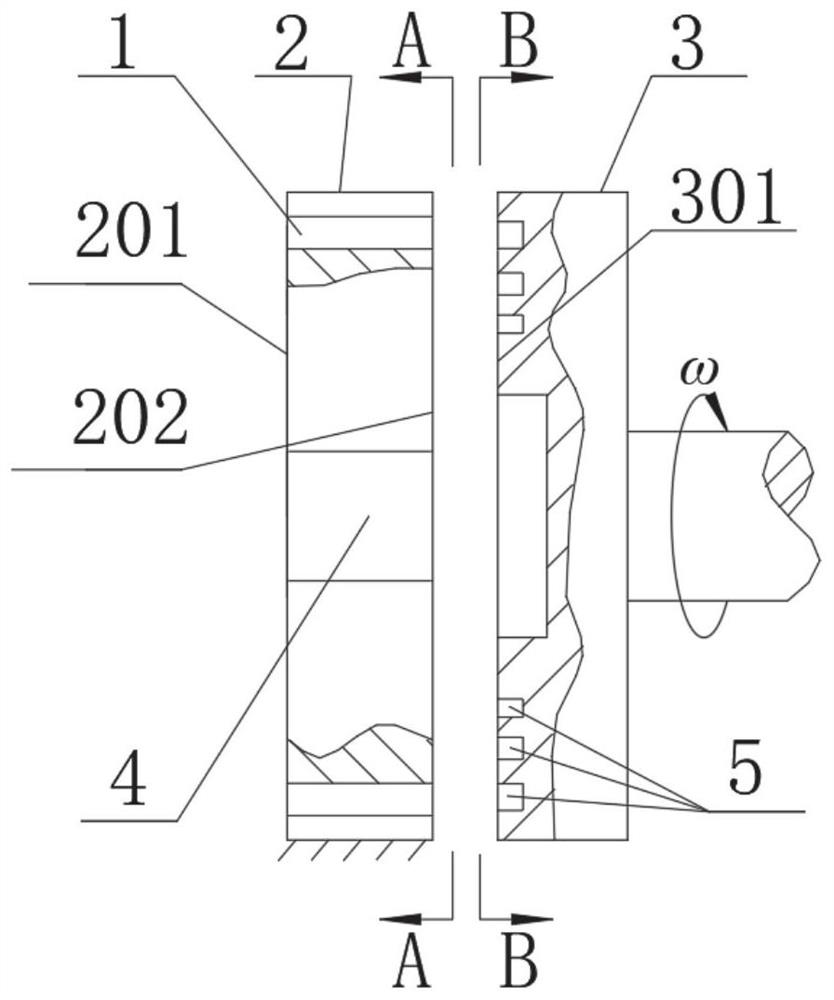

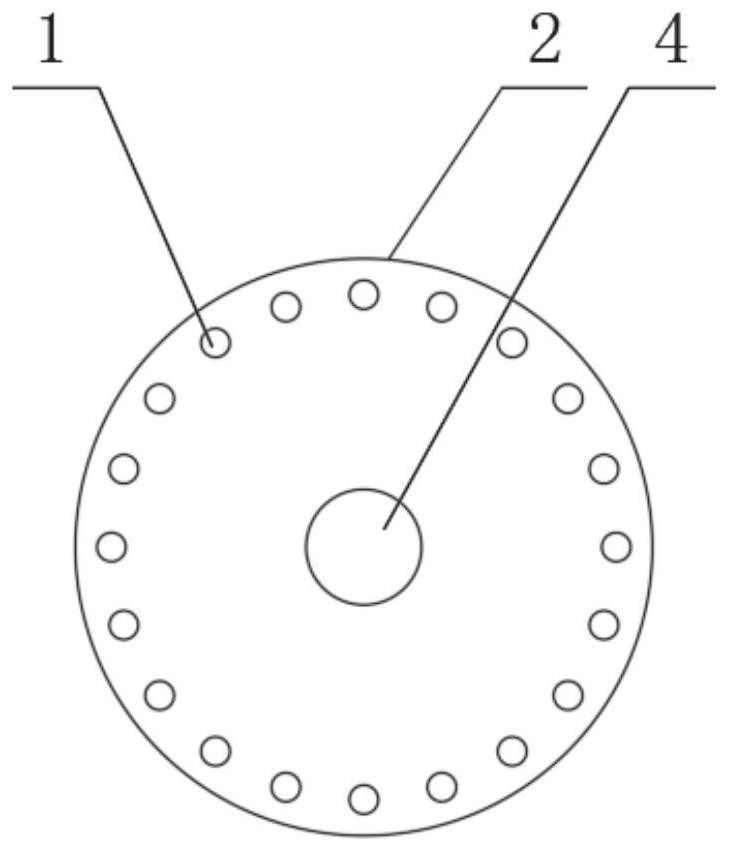

[0045] figure 2 It is a dynamic and static pressure spiral groove thrust bearing for water supply under normal pressure in a small hole, the thrust pad 1 is fixed, and the thrust disc 3 is used for rotating motion.

[0046] The outer diameter of the thrust tile 2 is 40mm, the diameter of the small hole 1 is 2mm, and the number is 20. The distance between the center of the small hole 1 and the center of the thrust tile 2 is 17.5mm, the thickness of the thrust tile is 8mm, and the diameter of the water outlet 4 is 8mm. The outer diameter of the disc 3 is 40 mm, the number of 5 spiral grooves is 12, the helix angle is 20°, the groove depth is 40 μm, the external water supply pressure is 0.15 MPa, and the thrust disc 3 rotates counterclockwise. Numerical simulation and experimental studies have concluded that: under light load conditions, the starting friction torque of the thrust bearing of the present invention is significantly smaller than that of a bearing of the same size wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com