Method for measuring non-contact type bearing startup friction torque and measuring instrument thereof

A friction torque, non-contact technology, applied in the direction of measuring devices, torque measurement, instruments, etc., can solve the problem of unable to quantitatively detect and control bearing friction performance, large error value, and unable to meet the detection and analysis of starting friction torque of small and medium-sized bearings and performance tests to solve the difficulties of transient measurement, improve reliability and accuracy, and improve friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

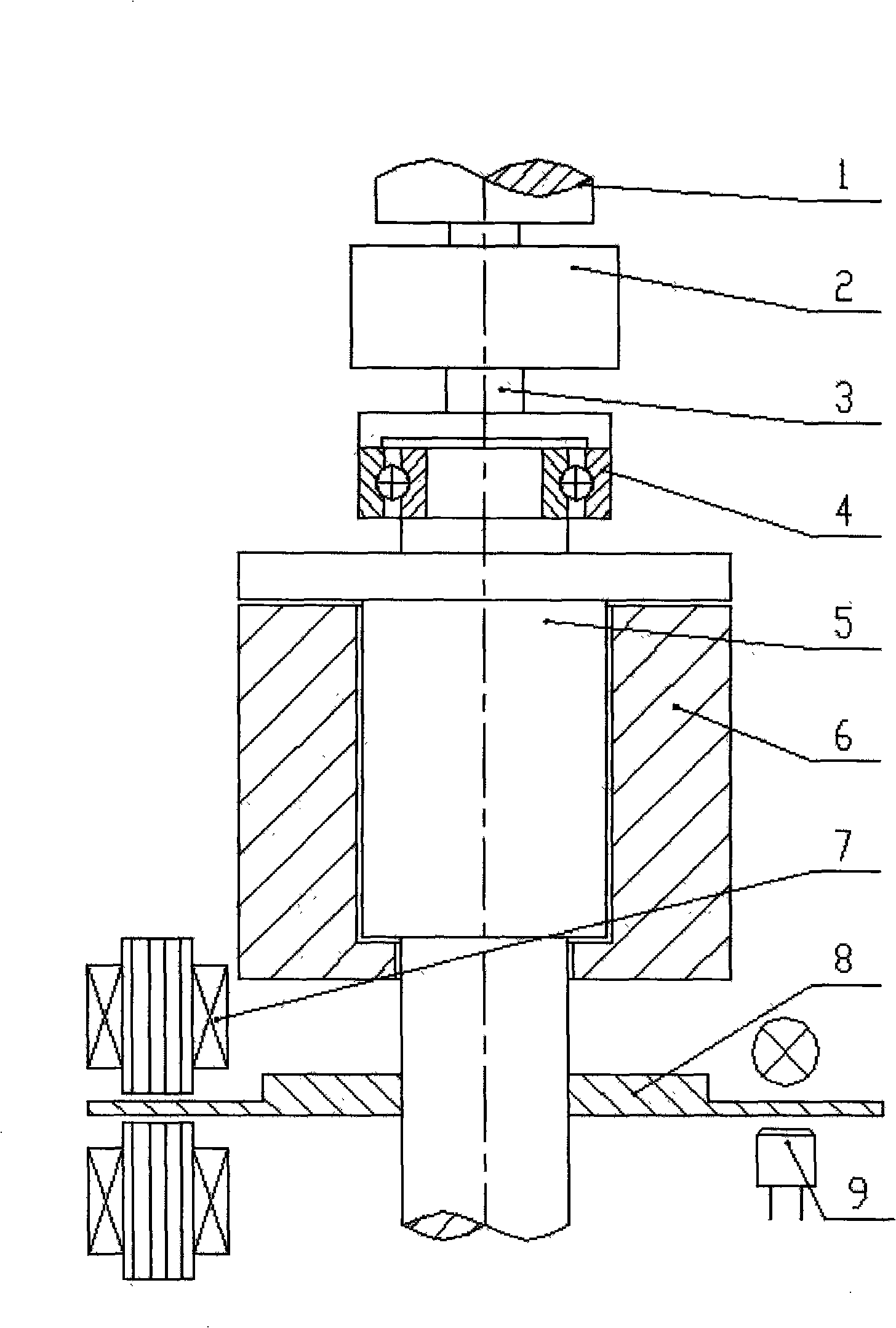

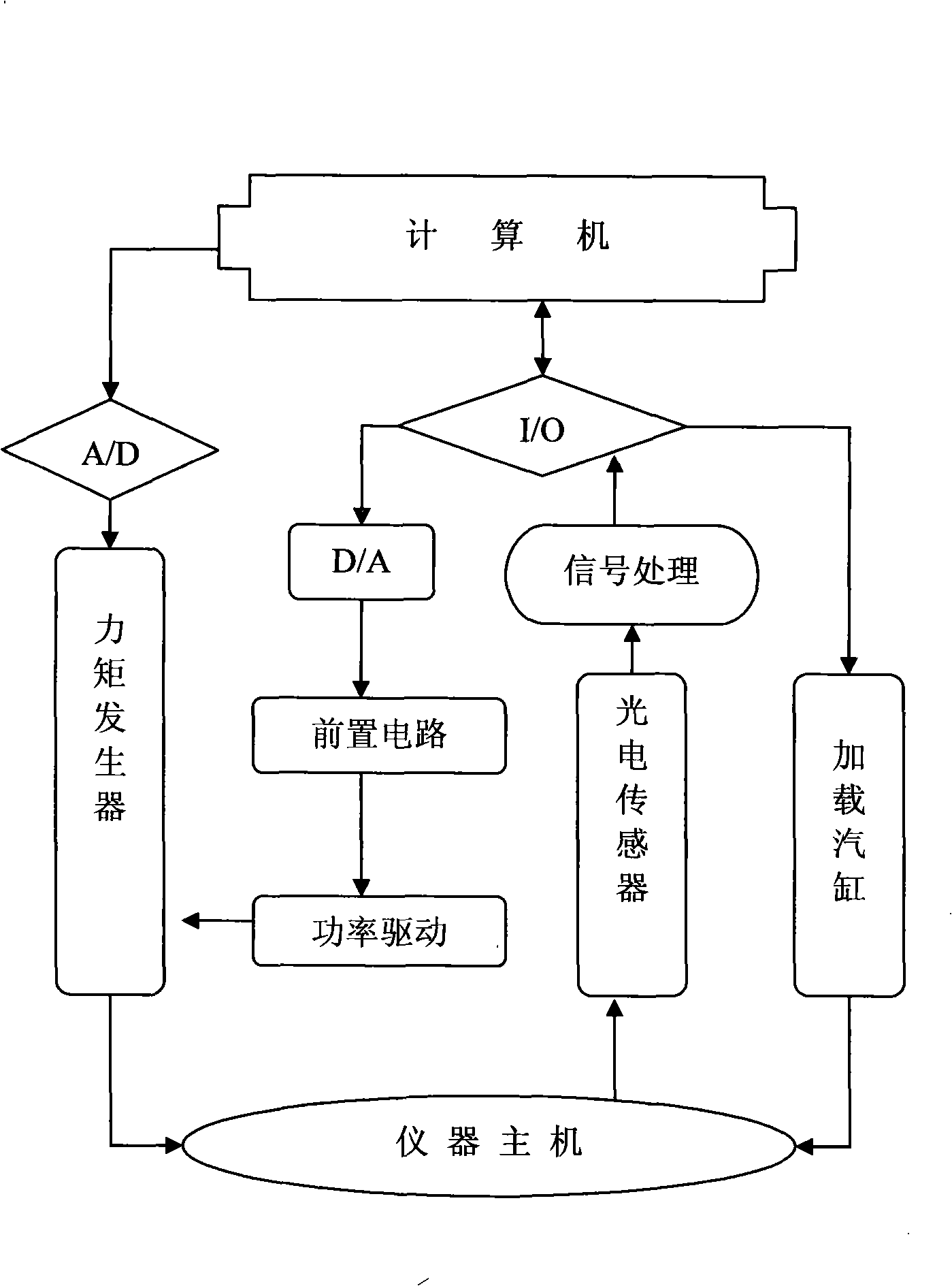

[0019] Such as figure 1 Shown: the measurement method of the present invention is first based on the measurement principle of the energy conversion method, uses a special torque generator (7) to generate the induced electromagnetic torque as the driving torque, and forms a closed-loop system with the photoelectric sensor (9) to automatically monitor the starting and running state of the bearing; Secondly, the air bearing (6) is used as a support to realize the non-contact automatic measurement of the starting friction torque value of the bearing; finally, during the measurement, the tested bearing (4) is installed on the air main shaft (6), and the driving disc is connected with the air main shaft, juxtaposed In the torque generator (7), after the axial load is applied to the tested bearing (4), the computer automatically controls the electrical system to gradually apply the input power to the torque generator (7). When the induced electromagnetic torque passes through the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com