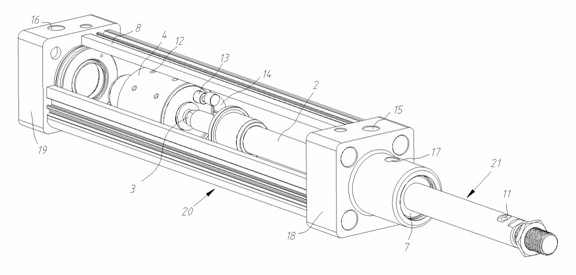

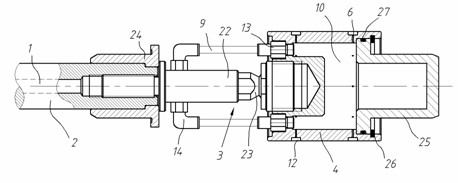

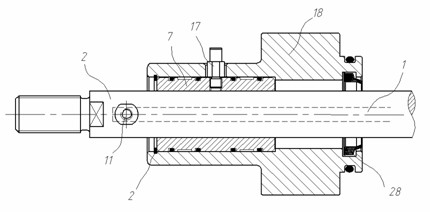

Zero-friction air cylinder with air bearing

A technology of frictionless cylinders and air bearings, applied in the direction of fluid pressure actuators, etc., can solve the problems of low friction, large stroke, radial load sensitivity, etc., and achieve the effects of reduced friction, simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention designs the piston part of the cylinder according to the principle of the air bearing on the basis of the ordinary cylinder, so that it forms a static pressure air bearing journal bearing with the inner wall of the cylinder barrel, and the contact part between the piston rod and the front end cover of the cylinder is the same The air bearing is used to connect, so that the non-contact connection between the movable part and the immovable part of the cylinder is realized, and the friction force is greatly reduced. The cylinder piston designed according to the principle of air bearings sprays compressed air from the inside of the piston to the tiny gap between the piston and the cylinder barrel through the orifices distributed in the circumferential direction of the piston, so that a high-pressure air film is formed in the gap Keep the piston out of contact with the cylinder barrel. When the piston is subjected to a certain radial force, such as a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com