Megawatt level wind power generation oar-changing bearing friction torque numeric control testing machine and test approach

A pitch bearing and friction torque technology, used in engine testing, mechanical bearing testing, machine/structural component testing, etc., can solve the problems such as the accuracy of the test results need to be considered, the cost and potential risks are high, and the operation is inconvenient. , to achieve the effect of perfect fault alarm setting, avoiding the influence of human factors, and intuitive friction torque curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

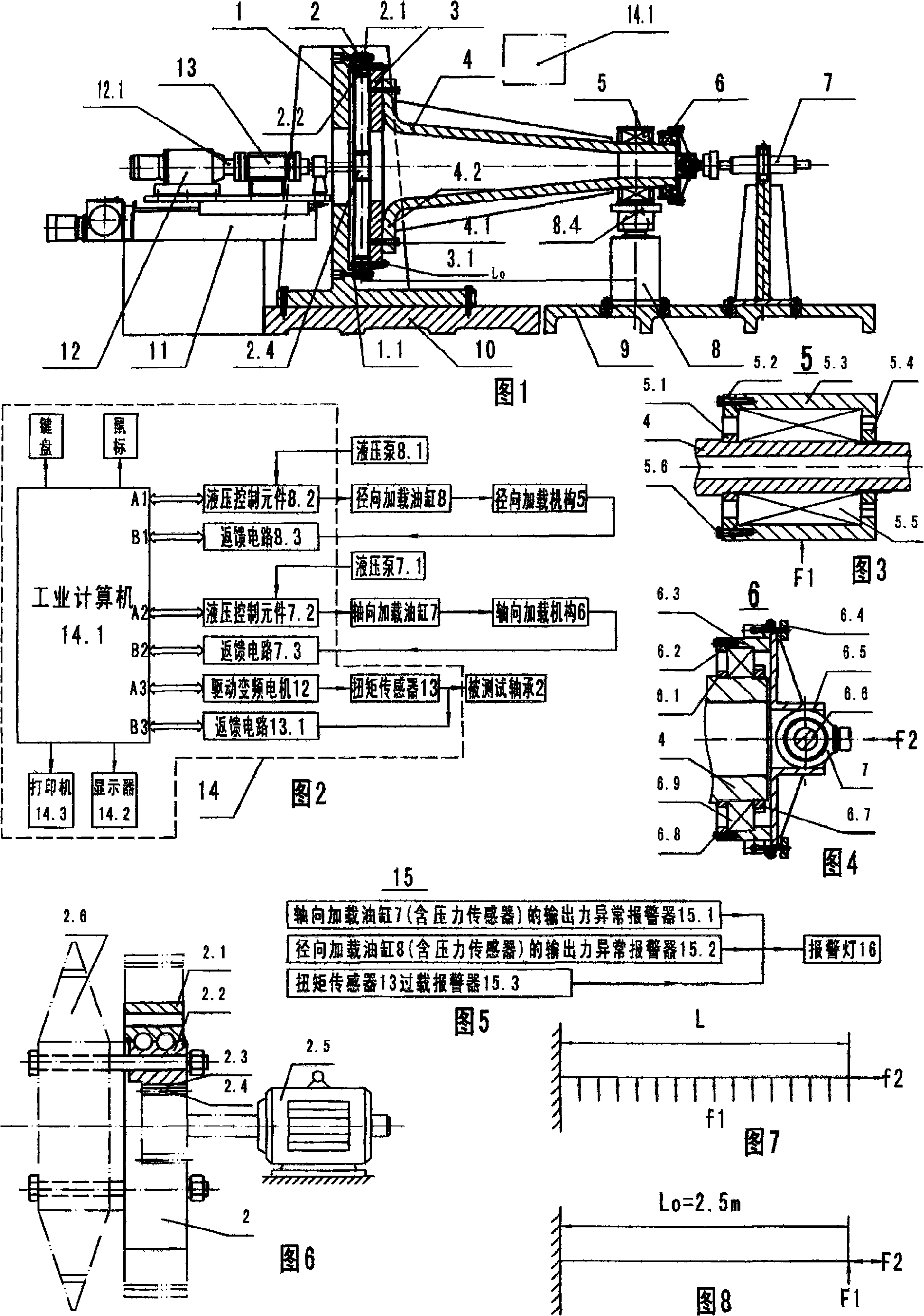

[0033] The structure of the numerical control testing machine for friction torque of the megawatt-level wind power pitch bearing in the embodiment of the present invention is as follows:

[0034] As shown in Fig. 1, fasten the bearing outer ring 2.1 of the measured wind power pitch bearing 2 to the vertical flat surface of the frame 1 with the connecting piece 1.1. (The outer ring 2.1 of the pitch bearing 2 of the wind turbine can be seen in Fig. 6 at the same time). The frame is formed by fixing two L plates on the base plate 10 . The loading system is formed as follows: the main shaft 4 is a hollow conical tube, one end is a large-diameter tube with a flange 4.2, and it is fixed on the connecting piece 3 with a screw 4.1, and the connecting piece 3 is fixed on the bearing inner ring 2.2 with a screw 3.1, and the main shaft 4 is separately One end is equipped with a hydraulic radial loading mechanism 5 added by a radial loading cylinder 8, and the end of the main shaft 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com