Eccentric screw pump having an automatic adjustment system and adjustment method

An eccentric screw pump, adjustment technology, applied in the direction of the pump, pump control, pump components, etc., can solve the problem of increasing the weight of the stator-rotor-system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

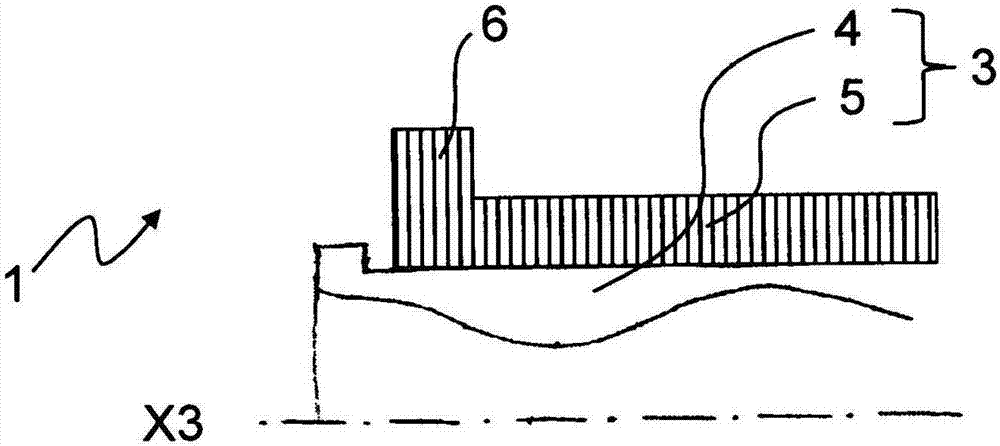

[0050] FIG. 1 shows a schematic partial view of a known stator-rotor system 1 for an eccentric screw pump. Such a system 1 comprises a generally metallic, single-filar helical rotor (not shown) and a stator 3 with double-filar threads. During operation of the eccentric screw pump, the rotor performs an eccentric rotational movement with its body axis about the longitudinal axis X3 of the stator. The stator 3 comprises an elastomer part 4 and a stator housing 5 , wherein there is no fixed connection between the elastomer part 4 and the stator housing 5 .

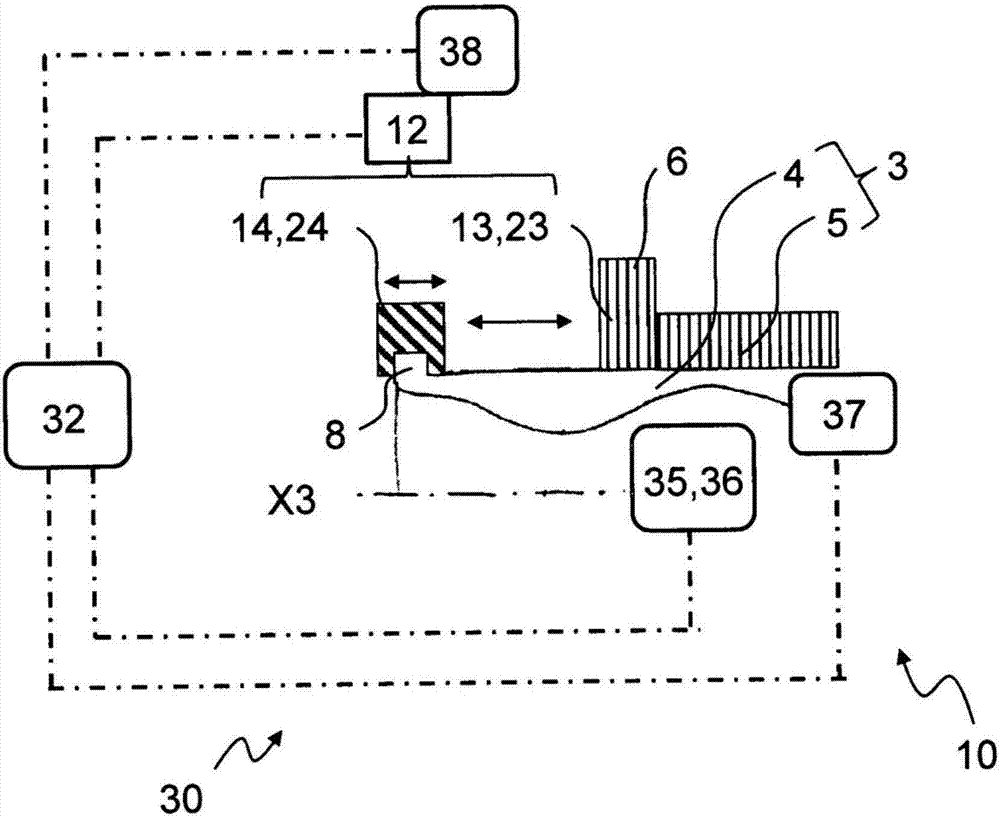

[0051] figure 2 A schematic partial view of a first embodiment of a stator-rotor system 10 according to the invention is shown, which has an adjusting mechanism 12 for fine adjustment or adjustment of the stator 3 . The adjustment mechanism 12 includes a fixed first adjustment element 13 and a second adjustment element 14 with a variable position. A change in the distance between the two setting elements 13 , 14 leads to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com