Parallel gripper

A parallel gripper and gripper technology, applied in the directions of clamping, chucking, support, etc., can solve the problems of low working efficiency, high cost and complex action of the mechanical gripper, and achieve high-efficiency clamping of the hub. , low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

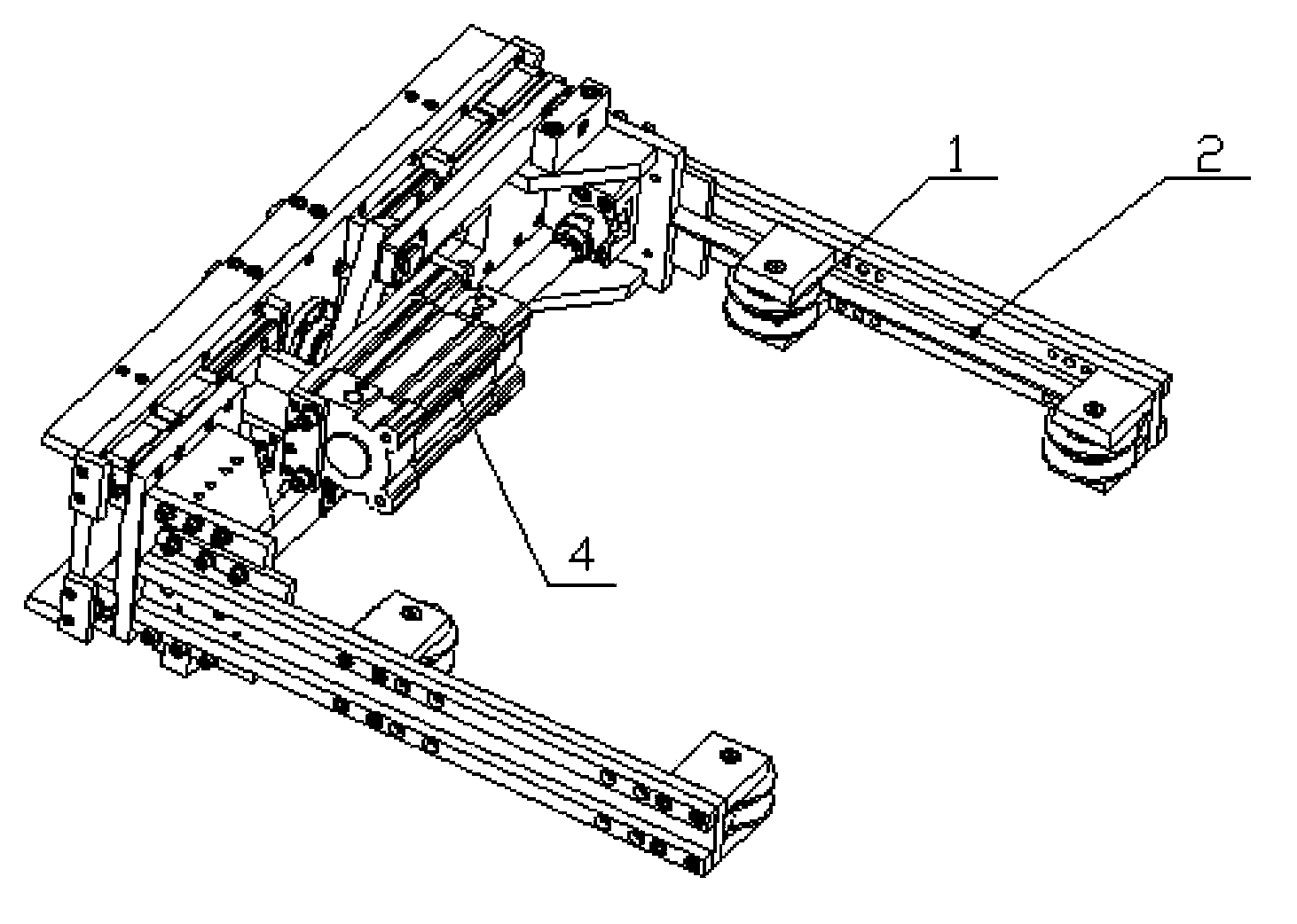

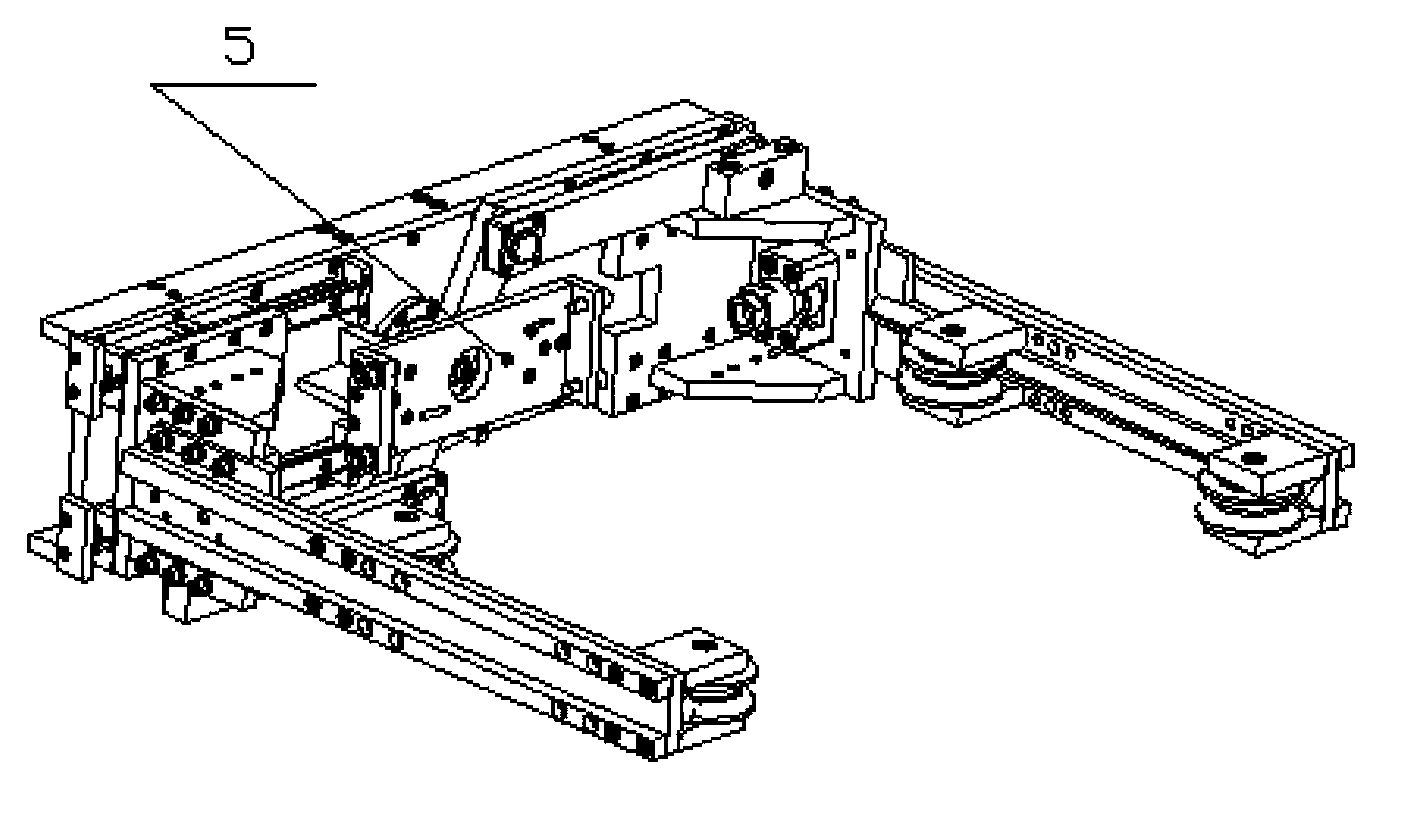

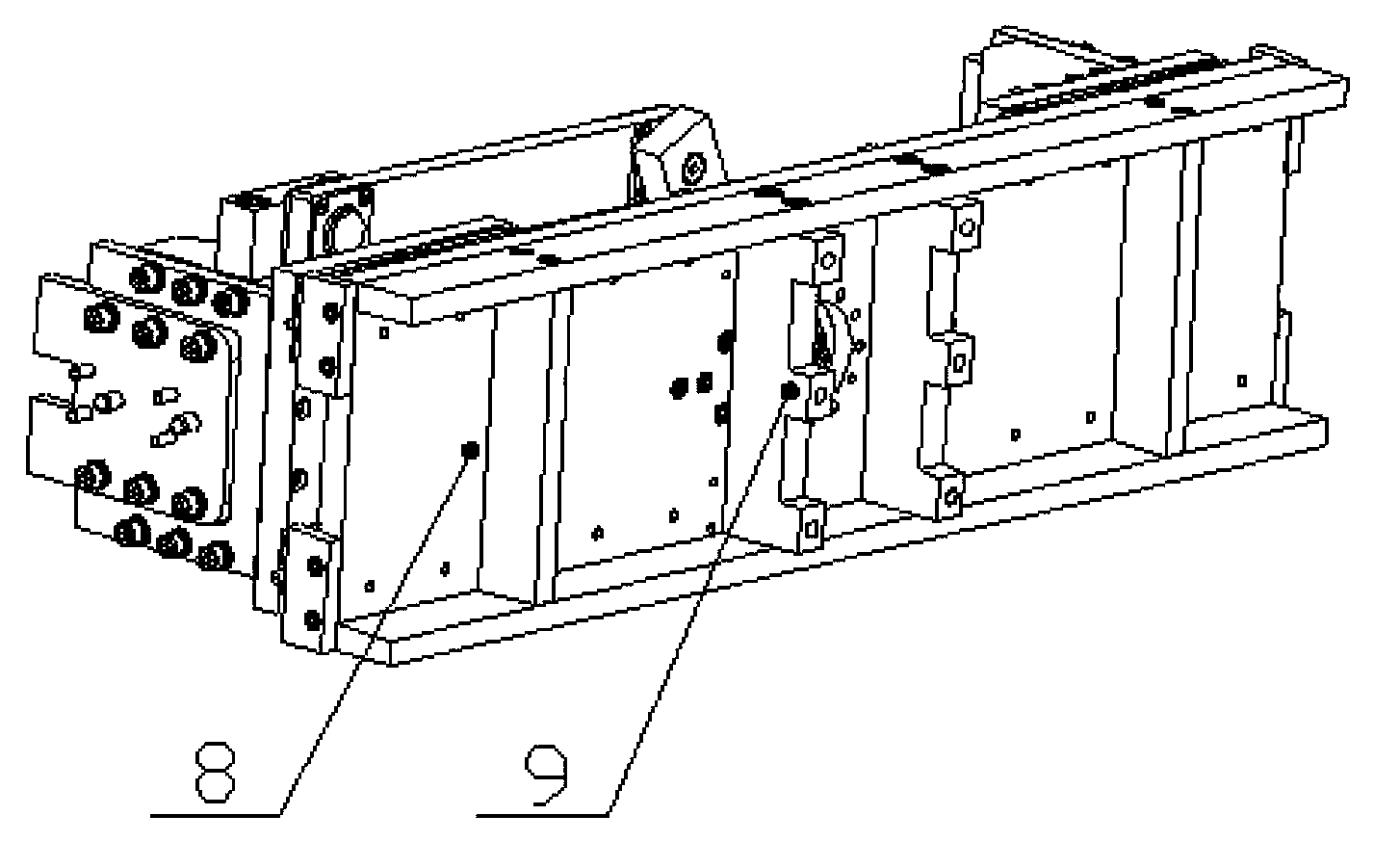

[0026] The invention discloses an effective parallel clamper. The parallel clamper has a simple structure, high reliability and high work efficiency under the premise of ensuring functional requirements and economic costs, and the mechanism is used as a The module can be quickly installed at the end of the robot arm without any changes to the existing structure.

[0027] The parallel clamper includes a base, a connection port arranged on the base, a pair of clamping beams, at least two rotating wheels respectively installed on the two clamping beams, a connecting block, and an air cylinder fixed on the base of the clamper The base, the cylinder installed on the cylinder base, the floating joint, and the center-symmetrical crank-slider mechanism installed on the holder base, the two clamping beams are respectively connected to the two ends of the center-symmetrical crank-slider mechanism through connecting blocks , the end of the cylinder is connected to the connection block th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com