Charging pile

A charging pile and charging gun technology, used in electric traction, electric vehicles, transportation and packaging, etc., can solve the problems of easy theft, shortened service life, and the gun wire is susceptible to ground friction, so as to avoid damage and extend the Longevity and effect of reducing the chance of theft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

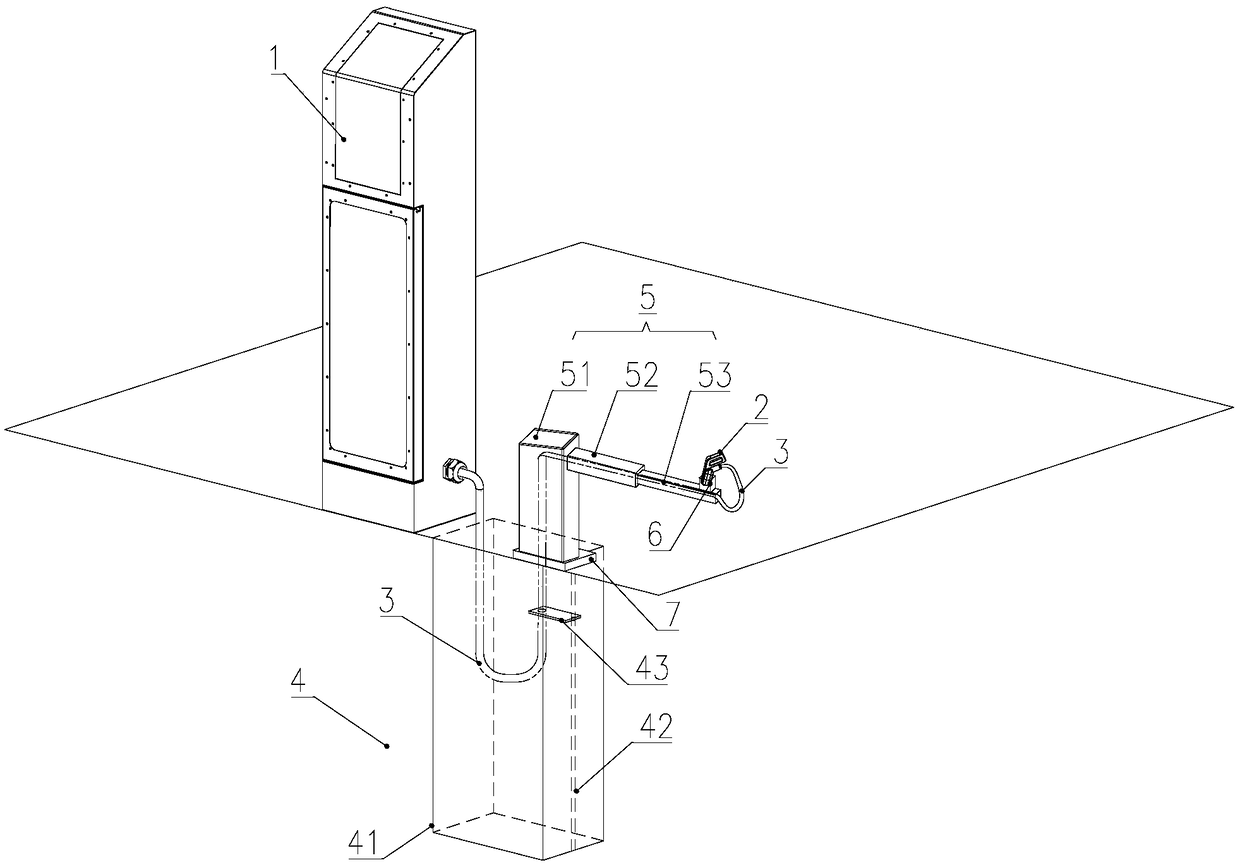

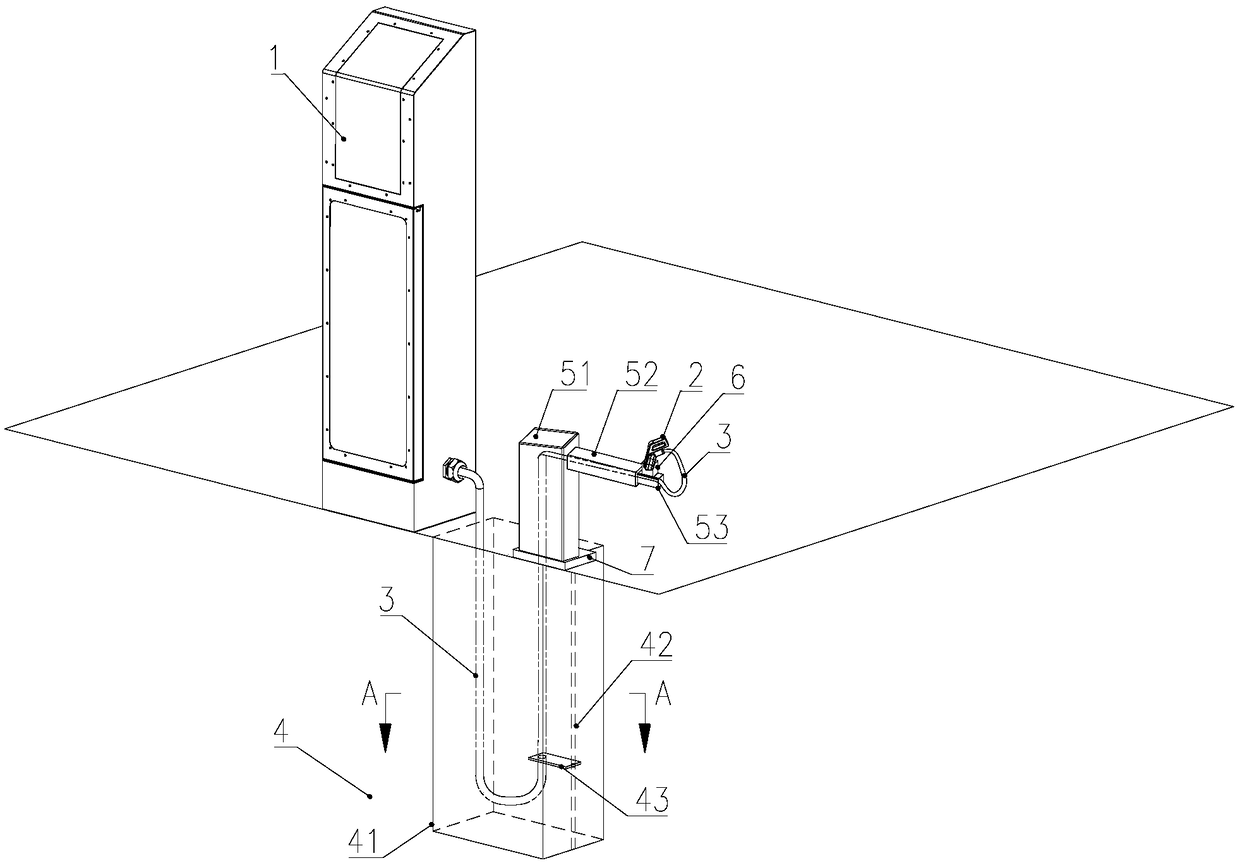

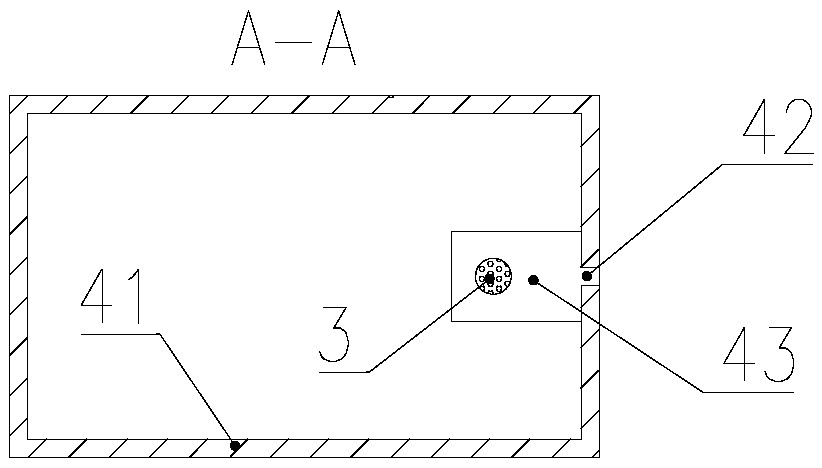

[0046] Such as figure 1 , figure 2 As shown, a charging pile includes a charging pile 1, a charging gun 2, and a charging wire 3. One end of the charging wire 3 is connected to the charging pile 1, and the other end is connected to the charging gun 2. The charging pile also includes a charging wire. The retractable device 4 and the bracket 5; wherein, the sliding device 43 is equipped with control equipment; the charging gun 2 is provided with an induction device, and the induction device is linked with the control equipment; the gun wire retractable device 4 is buried in Under the ground, it is used to store or release the gun wire 3; the bracket 5 is placed on the ground, and used to support the gun wire 3.

[0047] Such as Figure 4 As shown, the support 5 includes a vertical pole 51 arranged on the ground, a fixed pole 52 vertically connected with the vertical pole 51, and one or more movable poles 53, and the movable pole 53 is nested and connected with the fixed pole ...

Embodiment 2

[0063] The structural difference between this embodiment and Embodiment 1 is that, as Image 6 As shown, the gun wire supporting device is an electric winch 44 arranged at the bottom of the box body 41, instead of the chute 42 arranged on the surrounding wall of the box body 41 in Embodiment 1 and the slide that can move up and down along the chute 42 The device 43 is suitable for reducing the height of the box 41 in some places where it is not convenient to dig deep and bury the box 41, and only need to excavate the shallow ground to realize its anti-theft function; wherein, the electric winch 44 is equipped with There is control equipment; the charging gun 2 is provided with an induction device, and the induction device is linked with the control equipment.

[0064] In this embodiment, the working process of the charging pile 1 is as follows:

[0065] When the electric vehicle needs to be charged, the user parks the electric vehicle near the bracket 5, and conducts pre-char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com