Wear-resistant and heat-resistant EPDM (ethylene-propylene-diene monomer) sole material and preparation method thereof

A shoe sole material, EPDM56 technology, applied in the field of EPDM shoe sole material and its preparation, can solve problems such as weak binding force, poor heat aging resistance, and decreased wear resistance of shoe sole materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

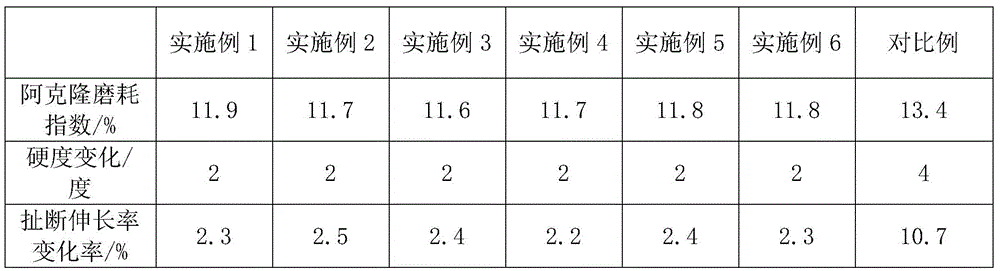

Examples

Embodiment 1

[0027] A kind of wear-resisting and heat-resistant EPDM shoe sole material, its weight part is composed of: 56 parts of EPDM, 8.5 parts of EVA, 1.2 parts of crosslinking agent BP, 12 parts of talcum powder, 3.5 parts of foaming agent OBSH, 2.4 parts of gum arabic , 0.6 parts of antioxidant DLTP, 4 parts of paraffin oil, 2.5 parts of accelerator TMTD, 4.2 parts of terpene resin, 4 parts of zinc oxide, 3 parts of zinc stearate, and 6 parts of modified aluminum oxide.

[0028] Its preparation method is:

[0029] A. Add PEG to water and disperse evenly to prepare a PEG aqueous solution with a concentration of 10%. Add a 10% ammonia solution to the magnesium aluminate aqueous solution. Stop adding when the pH value is 10. Stir until it is uniformly dispersed and then mixed. Solution, add the mixed solution into the PEG aqueous solution at a speed of 500L / H, continue to stir until it is completely converted into a gel, and stop adding to obtain a mixed gel;

[0030] B. Aging the mi...

Embodiment 2

[0035] A kind of wear-resisting and heat-resistant EPDM shoe sole material, its parts by weight are composed of: 60 parts of EPDM, 9 parts of EVA, 1 part of crosslinking agent BP, 10 parts of talcum powder, 5 parts of foaming agent OBSH, 2.8 parts of gum arabic, and 0.0 parts of antioxidant DLTP. 8 parts, 6 parts of paraffin oil, 2.1 parts of accelerator TMTD, 4 parts of terpene resin, 4 parts of zinc oxide, 3 parts of zinc stearate, 5.2 parts of modified aluminum oxide.

[0036] Its preparation method is the same as Example 1.

Embodiment 3

[0038] A kind of wear-resisting and heat-resistant EPDM shoe sole material, its parts by weight are composed of: 64 parts of EPDM, 8 parts of EVA, 1.5 parts of crosslinking agent BP, 8 parts of talcum powder, 4.5 parts of foaming agent OBSH, 2 parts of gum arabic, anti 1 part of oxygen agent DLTP, 8 parts of paraffin oil, 2.7 parts of accelerator TMTD, 4.8 parts of terpene resin, 4 parts of zinc oxide, 3 parts of zinc stearate, and 5.6 parts of modified aluminum oxide.

[0039] Its preparation method is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com