Angle steel painting device

An oiling device and angle steel technology, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as difficulty in ensuring quality, defects, and difficulty in evenly applying angle steel, so as to ensure the quality of painting and improve the The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

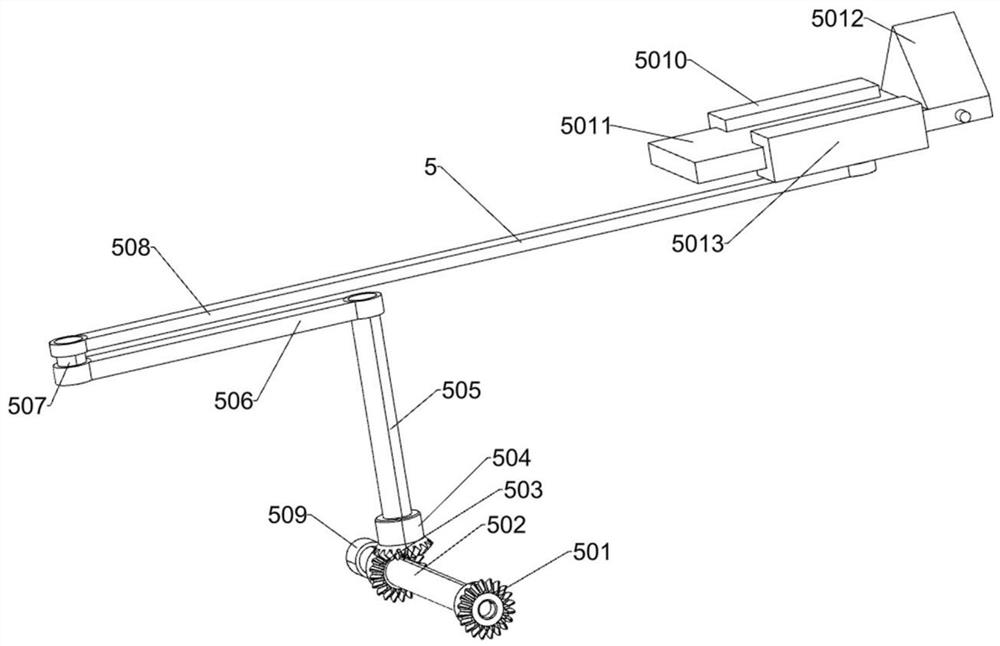

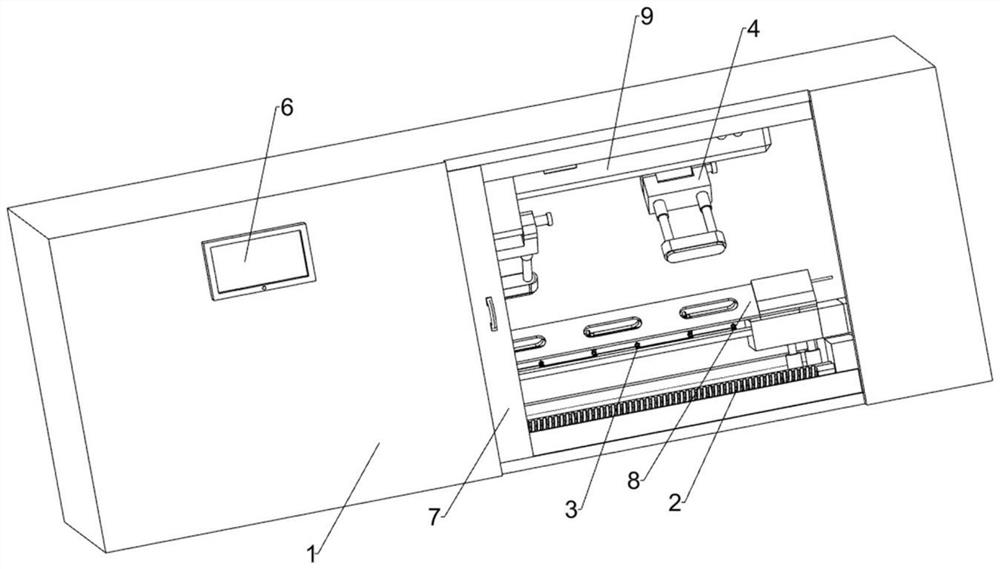

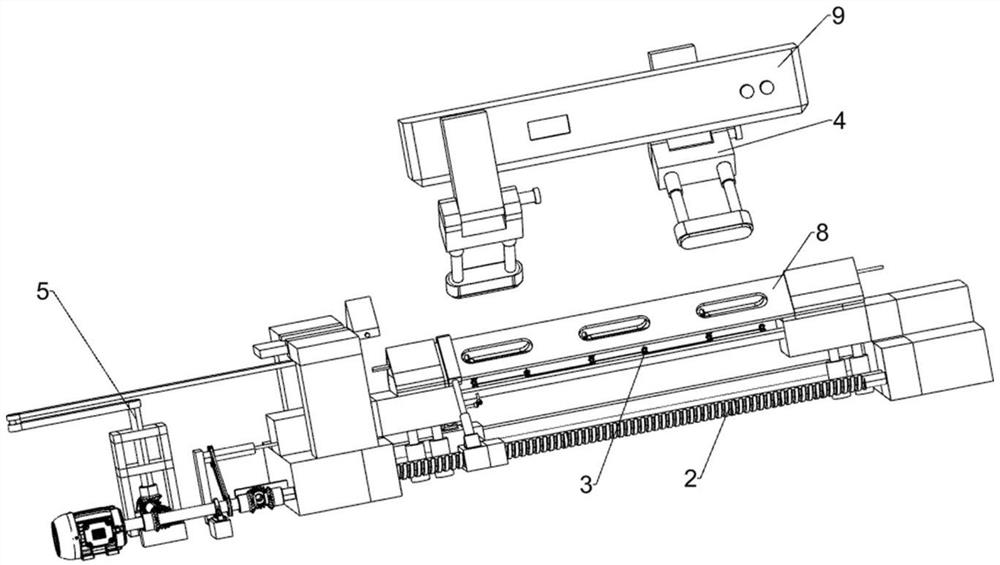

[0031] An angle steel oiling device, such as Figure 1-7 As shown, it includes a working room 1, an outer coating mechanism 2, a hole coating mechanism 3, a lifting and fixing mechanism 4, an inner coating mechanism 5, a control display screen 6, a work door 7, an angle steel 8 and a drying device 9; There are outer coating mechanism 2, hole coating mechanism 3, lifting and fixing mechanism 4, inner coating mechanism 5, working door 7, angle steel 8 and drying device 9; control display screen 6 is provided outside studio 1; outer coating mechanism 2 and holes The coating mechanism 3 is connected; the outer coating mechanism 2 is connected with the lifting and fixing mechanism 4; the outer coating mechanism 2 is connected with the inner coating mechanism 5; the lifting and fixing mechanism 4 is connected with the angle steel 8.

[0032] Working principle: When the device is in use, the various mechanisms in the studio 1 are controlled through the control display screen 6 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com