Annealing mechanism and enameled wire production system

A production system and enameled wire technology, applied in the direction of conductor/cable insulation, furnace, heat treatment equipment, etc., can solve problems such as difficulty, mechanical properties, chemical properties, electrical properties, thermal properties of enameled wires, and affect the quality of wire coating. , to achieve the effect of preventing damage and ensuring the quality of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

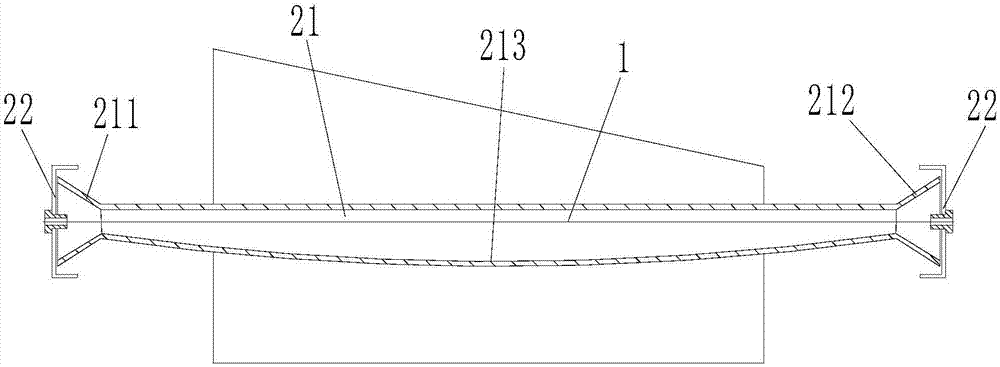

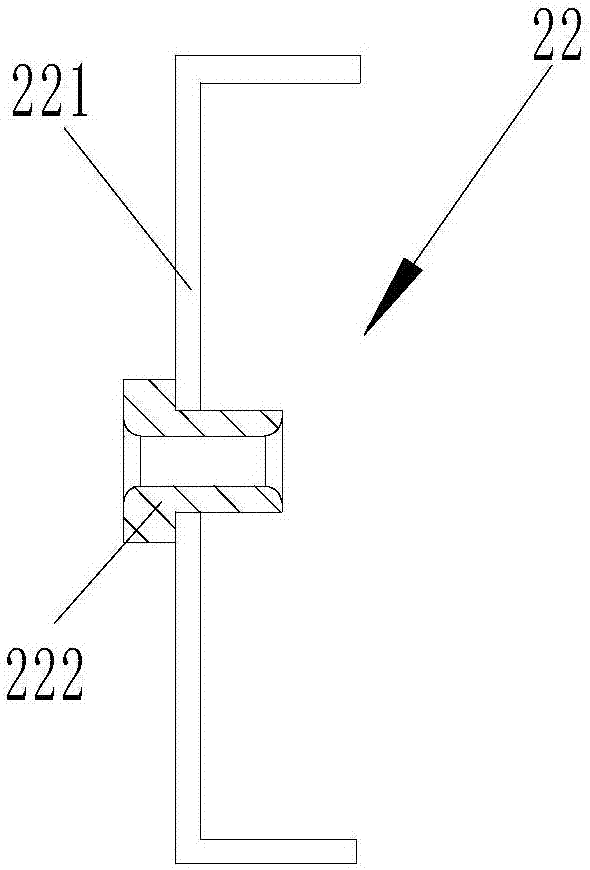

[0053] Such as figure 1 As shown, an annealing mechanism is used for annealing the wire body 1 after drawing, and the annealing mechanism includes an annealing tube 21 . The two ends of the annealing tube 21 are the wire inlet 211 and the wire outlet 212 respectively, and the inner wall 213 at the bottom of the annealing tube 21 is a downwardly concave arc. The wire body 1 enters the annealing pipe 21 from the wire inlet 211 , and is discharged from the wire outlet 212 after being heated by the annealing mechanism. In actual use, the wire body 1 enters the annealing tube 21 from the wire inlet 211 and is discharged from the wire outlet 212 by pulling the wire body 1 to keep the wire body 1 in a tensioned state. But because the wire body 1 enters the annealing tube 21 and will be heated, at this time due to thermal expansion and contraction, the part of the wire body 1 in the annealing tube 21 will sag, and the bottom inner wall 213 of the annealing tube 21 is used to be a dow...

Embodiment 2

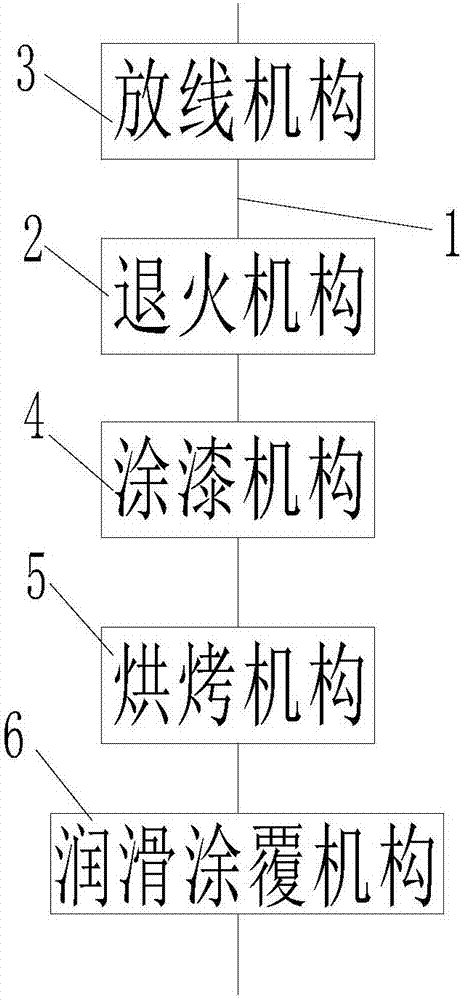

[0057] On the one hand, the present invention also provides an enameled wire production system, which is used to paint the wire body 1 after wire drawing, such as image 3 As shown, the enameled wire production system includes: the annealing mechanism 2 in the first embodiment, as well as the painting mechanism 4 and the baking mechanism 5 . The wire body 1 passes through the annealing mechanism 2, the painting mechanism 4 and the baking mechanism 5 in sequence. After the wire body 1 is annealed by the annealing mechanism 2, the paint liquid is applied to the surface of the wire body 1 through the painting mechanism 4, and then passed through the The roasting mechanism 5 roasts the wire body 1 .

[0058] It should be noted that after the thread body 1 is annealed by the annealing mechanism 2, the surface of the thread body 1 can be cleaned first (for example, the surface of the thread body 1 is cleaned with felt), and then the paint solution is applied by the painting mechanis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com